A kind of galanga polysaccharide and its preparation method and its application as an emulsifier to prepare slow-digesting emulsion

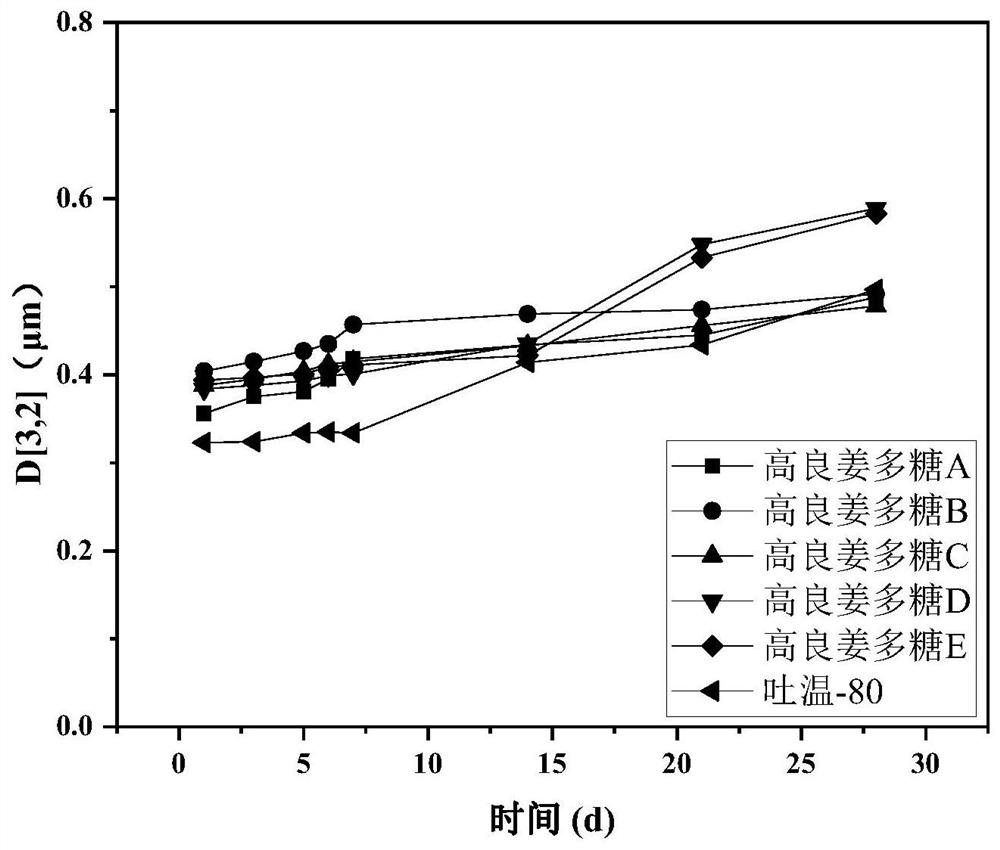

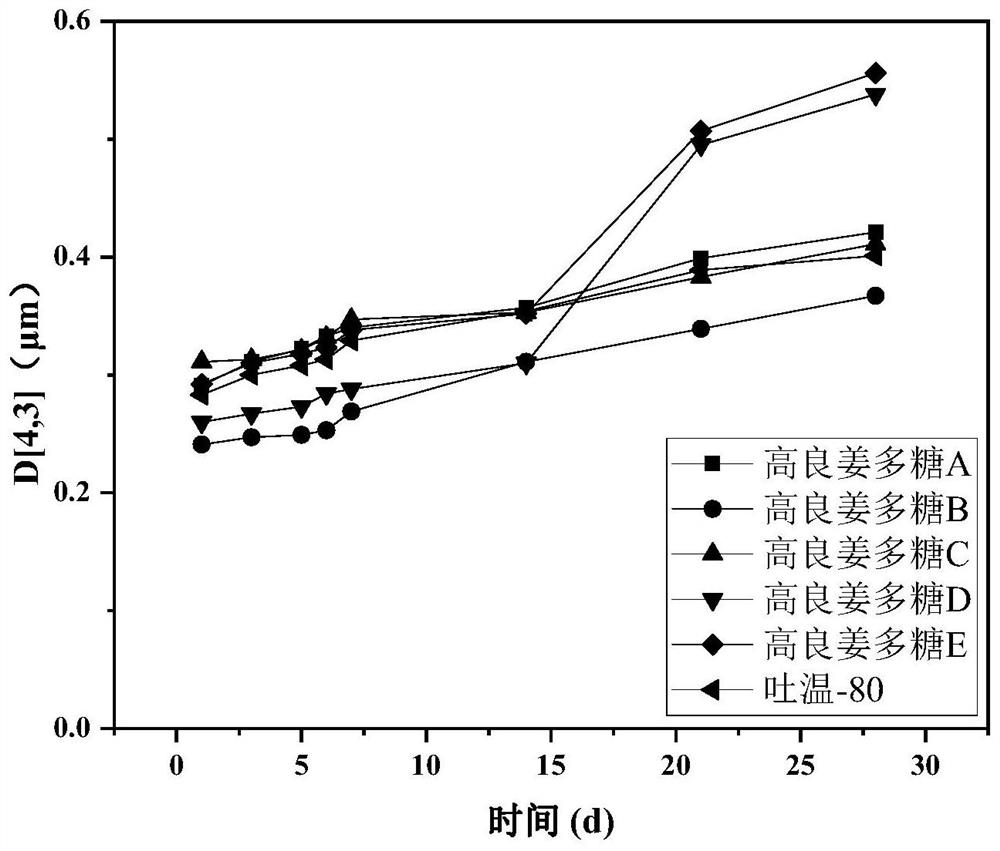

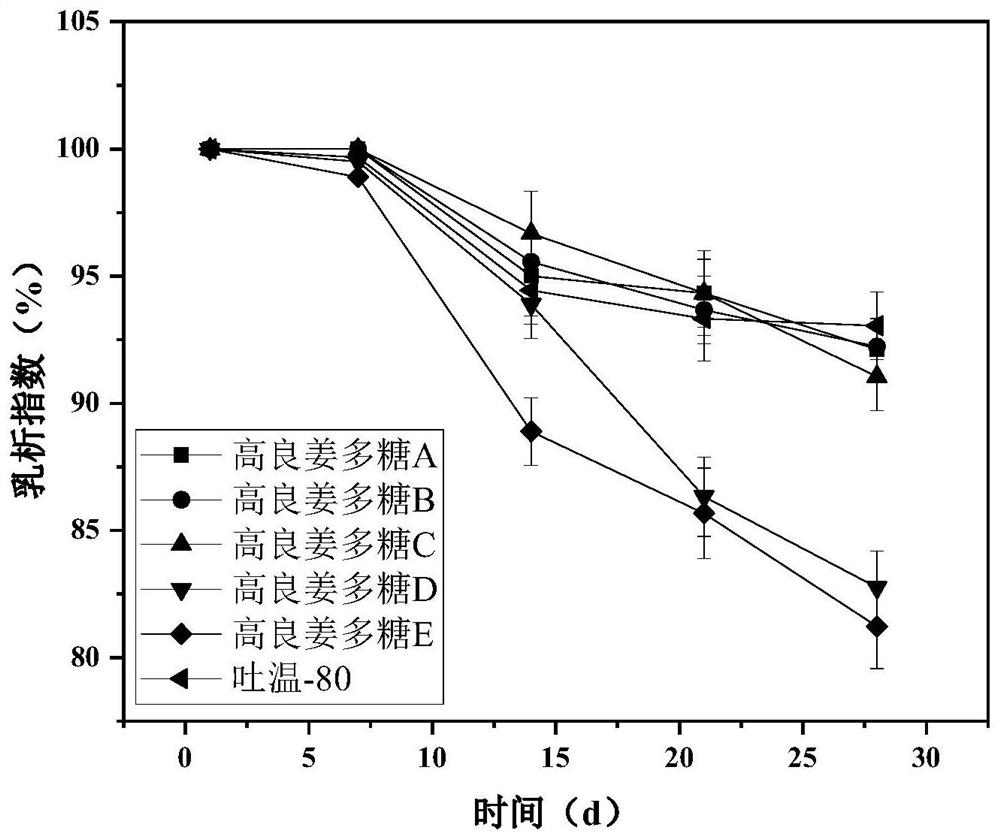

A technology of galangal and polysaccharides, which is applied in the direction of food ingredients as emulsifiers, application, polysaccharide/gum-containing food ingredients, etc., can solve the problems of limiting the application of galangal polysaccharides and low purity of crude polysaccharides, and achieve delay in lipid digestion. Effects of good stability and good lipid digestibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] A kind of method utilizing galanga polysaccharide as emulsifier to prepare slow-digestion emulsion, specifically comprises the steps:

[0080] (1) Grinding and sieving: Grinding dried galangal and passing it through a 40-mesh sieve to obtain galangal dry powder A1.

[0081] (2) ethanol thermal reflux to remove impurities: the galangal dry powder A1 obtained in step (1) is mixed with the ethanol solution and then the reflux extraction condition is: the concentration of the ethanol solution is 85% (v / v), and the concentration of the galangal dry powder A1 and the ethanol solution The ratio of solid to liquid is 1:8g / mL, the stirring rate is 200r / min, the extraction temperature is 75°C, the number of extractions is 2 times, and the time of each reflux extraction treatment is 0.5h. The centrifugation conditions after reflux extraction are: the centrifugal force is 4000g, and the centrifugation time is 15min. Discard the supernatant, dry the residue at 45°C, and dry for 3 h...

Embodiment 2

[0097] A kind of method utilizing galanga polysaccharide as emulsifier to prepare slow-digestion emulsion, specifically comprises the steps:

[0098] (1) Grinding and sieving: crush the dried galangal and pass it through a 40-mesh sieve to obtain dry galangal powder B1.

[0099] (2) ethanol thermal reflux to remove impurities: the galangal dry powder B1 obtained in step (1) is mixed with the ethanol solution, and the reflux extraction condition is: the concentration of the ethanol solution is 90% (v / v), and the concentration of the galangal dry powder B1 and the ethanol solution is The solid-liquid ratio was 1:9g / mL, the stirring rate was 300r / min, the extraction temperature was 80°C, the extraction times were 3 times, and the time for each reflux extraction treatment was 1h. The centrifugation conditions after reflux extraction are: the centrifugal force is 5000g, and the centrifugation time is 15min. Discard the supernatant, dry the residue at 50°C, and dry for 4 hours to o...

Embodiment 3

[0115] A kind of method utilizing galanga polysaccharide as emulsifier to prepare slow-digestion emulsion, specifically comprises the steps:

[0116] (1) Crushing and sieving: crush the dried galangal and pass through a 40-mesh sieve to obtain dry galangal powder C1.

[0117] (2) ethanol thermal reflux to remove impurities: the galangal dry powder C1 obtained in step (1) is mixed with the ethanol solution and the reflux extraction condition is: the concentration of the ethanol solution is 95% (v / v), and the concentration of the galangal dry powder C1 and the ethanol solution is The ratio of solid to liquid was 1:10g / mL, the stirring rate was 400r / min, the extraction temperature was 85°C, the number of extractions was 4 times, and the time for each reflux extraction treatment was 1.5h. The centrifugation conditions after reflux extraction are: the centrifugal force is 6000g, and the centrifugation time is 15min. Discard the supernatant, dry the residue at a temperature of 55°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com