Explosive compression molding method for improving charging density and density uniformity of special-shaped projectile body

A technology of density uniformity and compression molding, which is applied to ammunition, offensive equipment, weapon accessories, etc., can solve the problems of radial maximum density difference, low charge density, and poor density uniformity, so as to reduce density difference and improve charge volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

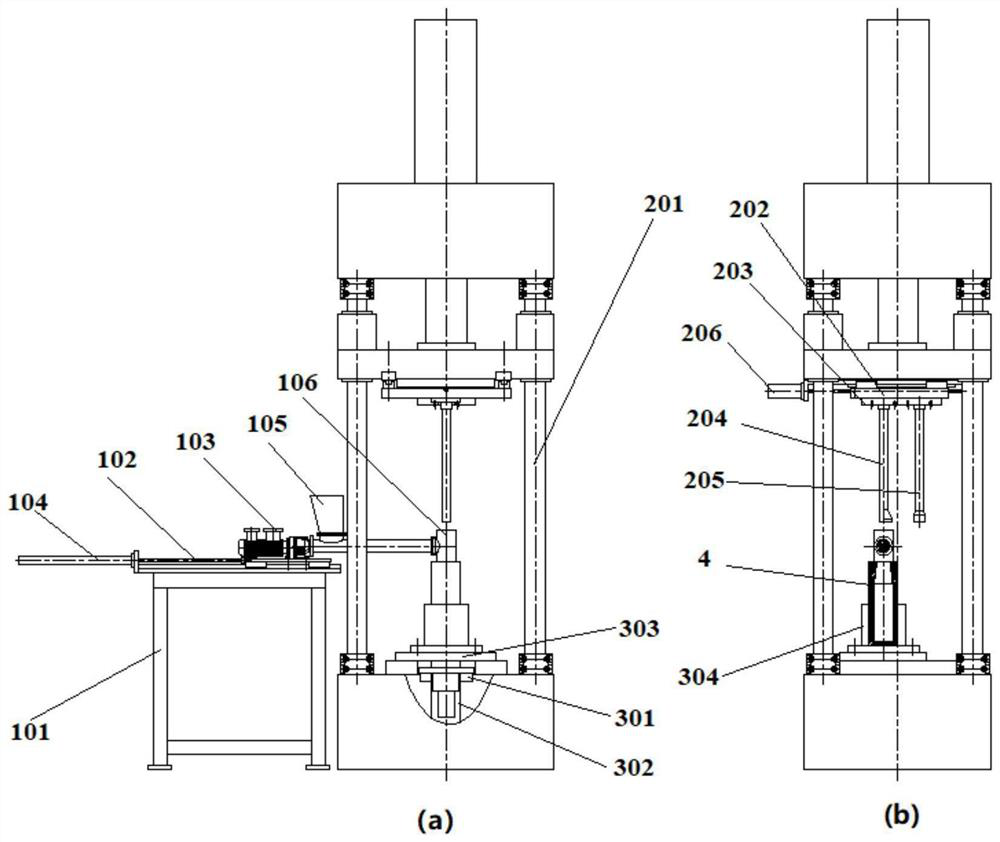

[0059] This embodiment provides an explosive compression molding method that improves the charge density and density uniformity of special-shaped projectiles. The explosive compression molding system used in the method includes an automatic feeding mechanism, a compression molding mechanism, a body fixing and rotating mechanism; the compression molding mechanism Located in the center, the automatic feeding mechanism is located on the rear side of the press-forming mechanism, and the body fixing and rotating mechanism are fixed at the center of the lower platform of the press-forming mechanism;

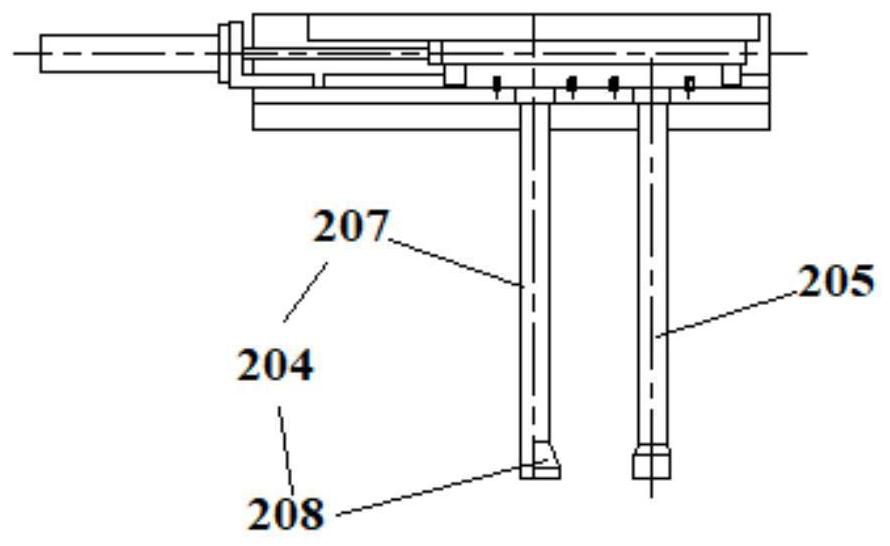

[0060] Automatic feeding mechanism comprises: frame 101, the first guide rail 102 that is fixed on the frame 101, the screw feeder 103 that is located on the first guide rail 102, the mobile cylinder 104 that is located at the first guide rail 102 rear, is located at the screw feeder The charging bin 105 that is communicated with the screw feeder 103 above the machine 103 and the feed f...

Embodiment 2

[0088] This embodiment provides an explosive compression molding method that improves the charging density and density uniformity of special-shaped projectiles. The explosive compression molding system used in the method includes an automatic feeding mechanism, a compression molding mechanism, a projectile body fixing and rotating mechanism; and each mechanism Same as embodiment 1, the differences between this embodiment and embodiment 1 are:

[0089] The method includes the following steps:

[0090] Step 1: set the feeding speed of screw feeder 103 to 12kg / h, and add explosive powder into feeding bin 105;

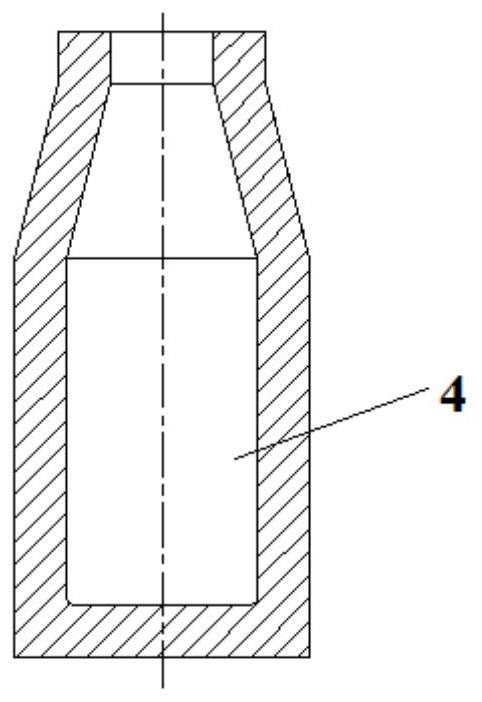

[0091] Step 2: Assemble the special-shaped mold 4 on the mold rotating part 303, and fix it in place by the chuck 304. The maximum diameter of the bottom of the special-shaped mold 4 is 114mm, and the diameter of the mouth is 70mm;

[0092] Step 3: Turn on the moving cylinder 104, move the feeding funnel 106 above the special-shaped mold 4, turn on the screw feeder 103 fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Large diameter | aaaaa | aaaaa |

| Mouth diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com