Cold extrusion steel seamless four-way pipe manufacturing process

A manufacturing process, cold extrusion technology, which is applied in the field of cold extrusion steel seamless four-way manufacturing process, can solve the problems of uneven thickness of joints, complicated preparation procedures, and short service life in the later period, so as to ensure service life and manufacture Simple, safe and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

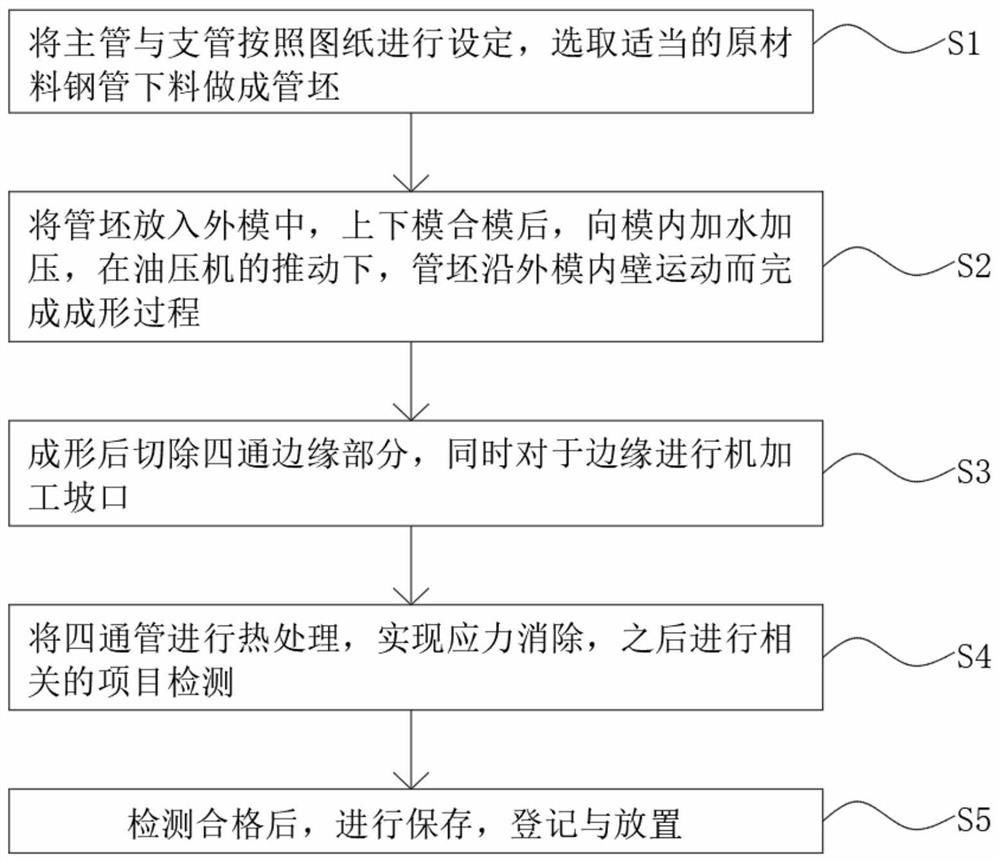

[0021] Such as figure 1 As shown, the present invention provides a technical solution, a cold-extruded steel seamless four-way manufacturing process, including the following steps:

[0022] S1. Set the main pipe and the branch pipe according to the drawing, and select the appropriate raw material steel pipe to blank to make the pipe blank;

[0023] S2. Put the tube blank into the outer mold, after the upper and lower molds are closed, add water and pressure to the mold, and under the push of the hydraulic press, the tube blank moves along the inner wall of the outer mold to complete the forming process;

[0024] S3. Cut off the edge part of the four-way after forming, and machine the bevel to the edge at the same time;

[0025] S4. Carry out heat treatment to the four-way pipe to realize stress relief, and then carry out related project inspections;

[0026] S5. After passing the test, save, register and place.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com