A kind of preparation method of low-shrinkage nylon 66 industrial yarn

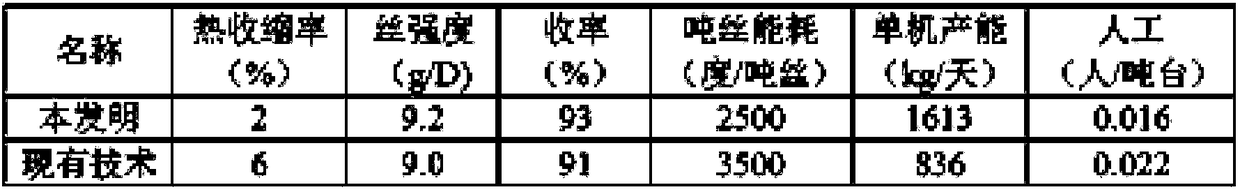

An industrial yarn and low-shrinkage technology, which is applied in the field of nylon spinning, can solve the problems of safety hazards and low production efficiency, and achieve the effects of low shrinkage, good electrical insulation, and ensuring smoothness and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032]A preparation method of low-shrinkage nylon 66 industrial yarn, the thermal shrinkage rate of the prepared nylon 66 industrial yarn is 2%, the denier is 100D, the breaking strength is 9.2g / D, and the breaking elongation is 19%. Include the following steps:

[0033] (1) Transport nylon 66 slices with an initial moisture content of 3000ppm and an initial relative viscosity of 2.20 to the drying tower, turn on the vacuum pump, and dry them in N with an oxygen content of ≤5ppm and a temperature of 145°C. 2 Drying and polymerization reaction are carried out under protection, the pressure inside the drying tower is 6kPa, the reaction temperature is 145°C, the reaction time is 30h, the moisture content of the slice after reaction is 400ppm, and the relative viscosity is 2.60;

[0034] (2) The polyamide fiber 66 slice after step (1) drying is carried out humidity-conditioning treatment, regulates the moisture content and the viscosity of slice again, and the moisture content of ...

Embodiment 2

[0047] A preparation method of low-shrinkage nylon 66 industrial yarn, the thermal shrinkage rate of the prepared nylon 66 industrial yarn is 1.98%, the denier is 840D, the breaking strength is 9.5g / D, and the breaking elongation is 20%. Include the following steps:

[0048] (1) Transport nylon 66 slices with an initial moisture content of 3000ppm and an initial relative viscosity of 2.23 to the drying tower, turn on the vacuum pump, and dry them in N with an oxygen content of ≤5ppm and a temperature of 150°C. 2 Drying and polymerization reaction are carried out under protection, the pressure inside the drying tower is 6kPa, the reaction temperature is 150°C, the reaction time is 36h, the moisture content of the slice after reaction is 350ppm, and the relative viscosity is 2.60;

[0049] (2) The nylon 66 slice dried in step (1) is subjected to humidity-conditioning treatment, and the moisture content and viscosity of the slice are adjusted again. The slices are sent to the hu...

Embodiment 3

[0062] A preparation method of low-shrinkage nylon 66 industrial yarn, the thermal shrinkage rate of the prepared nylon 66 industrial yarn is 1.95%, the denier is 1890D, the breaking strength is 9.8g / D, and the breaking elongation is 22%. Include the following steps:

[0063] (1) Transport nylon 66 slices with an initial moisture content of 5000ppm and an initial relative viscosity of 2.26 to the drying tower, turn on the vacuum pump, and dry them in N at an oxygen content of ≤5ppm and a temperature of 150°C. 2 Drying and polymerization reaction are carried out under protection, the pressure inside the drying tower is 6kPa, the reaction temperature is 150°C, the reaction time is 36h, the moisture content of the slice after reaction is 400ppm, and the relative viscosity is 2.70;

[0064] (2) The polyamide fiber 66 slice after step (1) drying is carried out humidity-conditioning treatment, regulates the moisture content and the viscosity of slice again, and the moisture content ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com