A method for automatic adjustment of process parameters for single crystal silicon rod cutting

A technology of automatic adjustment and process parameters, applied in the direction of manufacturing tools, work accessories, stone processing equipment, etc., can solve the problems of affecting the quality of crystalline silicon cutting, low efficiency of manual adjustment, etc., to improve cutting quality, reduce manual intervention, and save costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

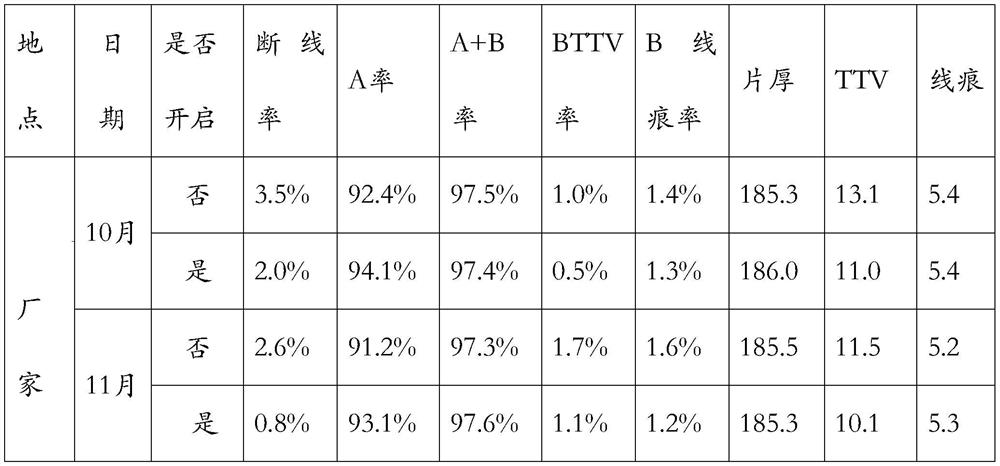

Embodiment 1

[0024] The method and equipment are suitable for the multi-wire cutting process of slicing. The multi-wire cutting device includes two horizontally distributed left and right cutting rollers. The cutting rollers have wire grooves and are covered with wire meshes. The wire meshes are made of gold steel wire. The gold steel wire enters the wire along the wire entry end of the left cutting roll, and the two main rolls are covered along the wire groove, and the wire exits from the steel wire outlet end of the right cutting roll. The gold steel wire enters from the incoming end, and after the outgoing end comes out, it is connected to the gold steel wire take-up and pay-off control device through a small guide wheel. , acceleration and deceleration and line tension; this program needs to have the functions of automatically collecting cutting information and automatically adjusting process parameters. Include the following steps:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com