A method for preparing antimony sulfide powder by flash heat treatment

An antimony sulfide, flash technology, applied in antimony sulfide, chemical instruments and methods, inorganic chemistry and other directions, to achieve the effect of controlling production costs, low production costs, and low temperature requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: The heating method used in this example is plasma heating, the protective gas is argon, and the carrier gas is argon

[0034] A kind of flash heat treatment to prepare antimony sulfide (Sb 2 S 3 ) powder method, the concrete steps are as follows:

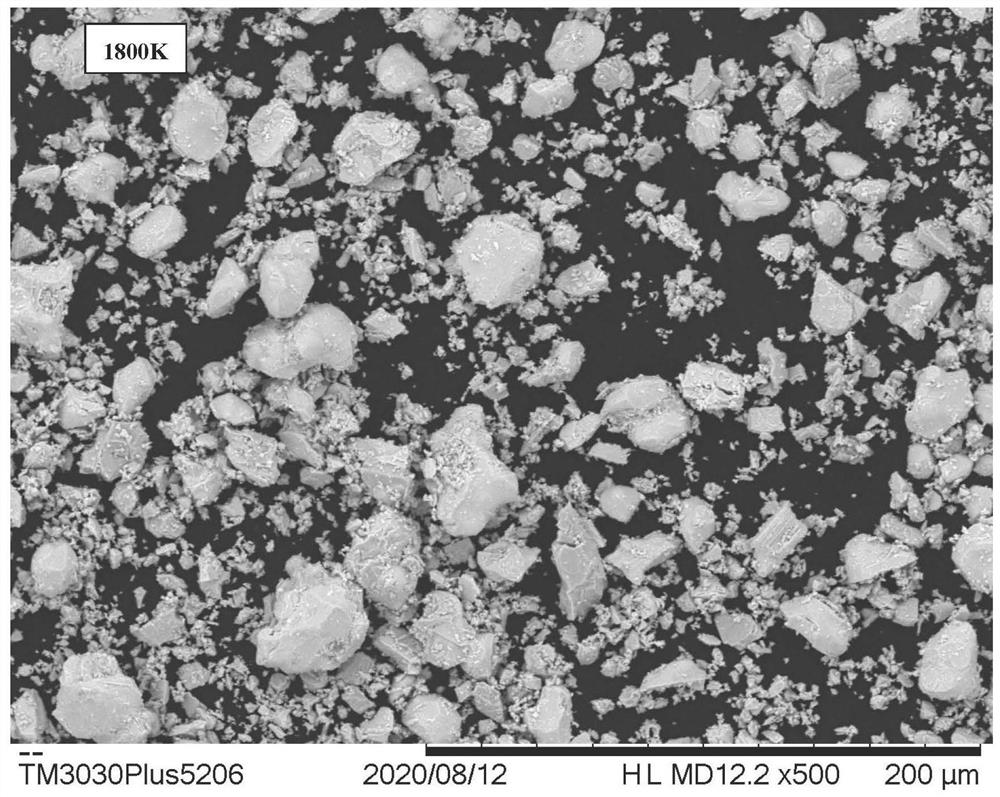

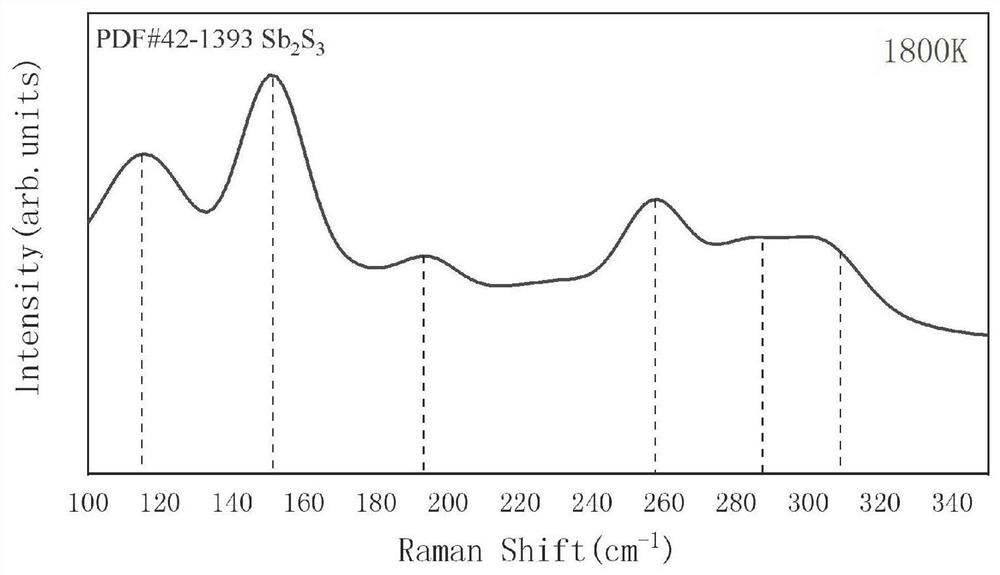

[0035] (1) Put 0.5mol sulfur powder (99% in purity) and 0.2mol antimony powder (99.9% in purity) into the feeding device, turn on the argon excitation gas source, enter the vertical plasma heating reactor, and turn on the plasma Power on and start the plasma, set the plasma power to 1500W, and raise the temperature to the target temperature of 1800K. In order to ensure that the high-temperature reaction area is fully heated to the set temperature, the system is heated up slowly, and the heating time is set to 115min;

[0036] (2) The sulfur powder and antimony powder are transported to the flash heat treatment high temperature zone (1800K plasma heating zone) in the vertical plasma heating reactor through the car...

Embodiment 2

[0039] Embodiment 2: The heating method adopted in this embodiment is plasma heating, the protective gas is xenon, and the carrier gas is hydrogen;

[0040] A kind of flash heat treatment to prepare antimony sulfide (Sb 2 S 3 ) powder method, the concrete steps are as follows:

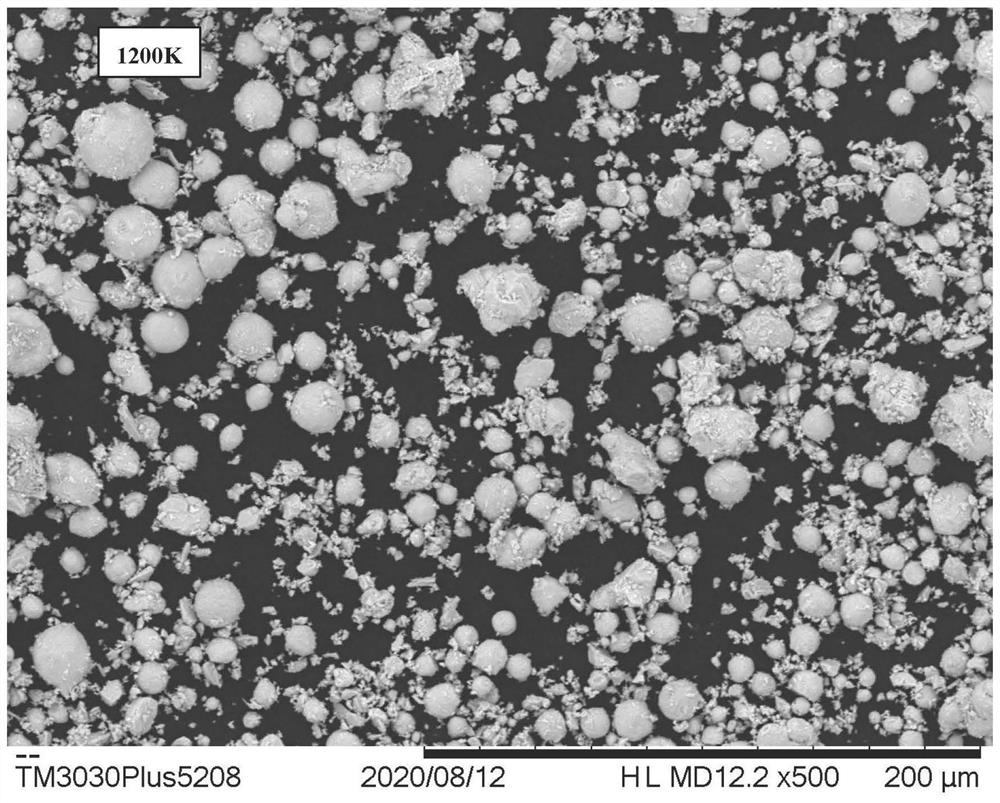

[0041](1) Put 0.45mol sulfur powder (99.99% in purity) and 0.2mol antimony powder (99% in purity) into the feeding device, turn on the xenon excitation gas source, enter the vertical plasma heating reactor, and turn on the plasma power And start the plasma, set the plasma power to 1100W, and raise the temperature to the target temperature of 1200K. In order to ensure that the high-temperature reaction area is fully heated to the set temperature, the system is heated up slowly, and the heating time is set to 125min;

[0042] (2) The sulfur powder and antimony powder are transported to the flash heat treatment high temperature zone (1200K plasma heating zone) in the vertical plasma heating reactor thro...

Embodiment 3

[0045] Embodiment 3: The heating method adopted in this embodiment is thermocouple heating, the protective gas is helium, and the carrier gas is a mixture of hydrogen sulfide and methane with a molar ratio of 1:1;

[0046] A kind of flash heat treatment to prepare antimony sulfide (Sb 2 S 3 ) powder method, the concrete steps are as follows:

[0047] (1) Put 0.4mol sulfur powder (purity: 99.9%) and 0.2mol antimony powder (purity: 99.9%) in the feeding device, open the argon excitation gas source, enter the vertical high-temperature reactor, and turn on the thermocouple power supply , raise the temperature to the target temperature of 900K, in order to ensure that the high-temperature reaction area is fully heated to the set temperature, the system is slowly heated up, and the heating time is set to 90min;

[0048] (2) The sulfur powder and antimony powder are transported to the flash heat treatment high temperature zone (900K plasma heating zone) in the vertical high tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com