Preparation method of isobutyric acid

A technology of isobutyric acid and isobutyraldehyde, which is applied in the field of isobutyric acid preparation, can solve the problems of long reaction time and easy explosion, and achieve the effects of avoiding explosion accidents, increasing reaction speed, and improving atom economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] In a first aspect, the present invention provides a method for preparing isobutyric acid, wherein the method comprises: contacting the atomized droplets of a mixture of isobutyraldehyde and water with an oxygen-containing gas to generate isobutyric acid, and Based on the total weight of the mixed liquid, the content of the water is 20-50% by weight.

[0043] In the method of the present invention, the concentration of reactants and the contact area are increased by adopting the atomization mode of isobutyraldehyde, the reaction residence time is shortened, and the reaction speed is increased simultaneously.

[0044] The atomized droplets of the mixture of isobutyraldehyde and water in the present invention can be formed by passing the mixture of isobutyraldehyde and water through an atomizing nozzle, but the formation method is not limited thereto.

[0045] There is no particular limitation on the concentration of the above-mentioned mixed solution. In order to improve ...

Embodiment 1

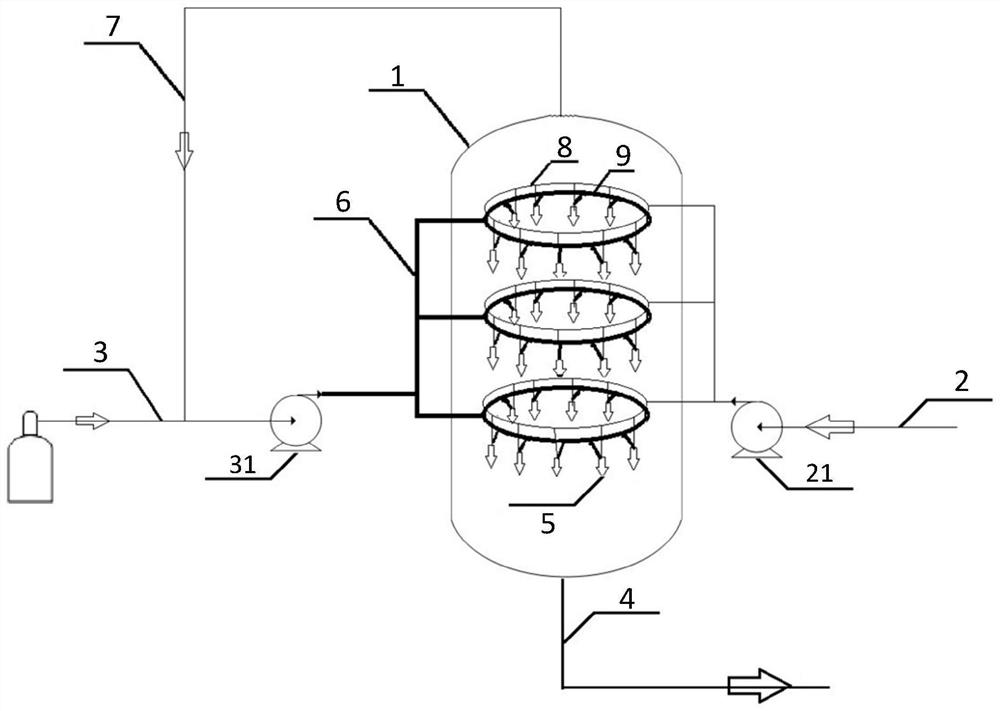

[0072] exist figure 1 Carry out the preparation of isobutyric acid in the shown device, at first in reactor 1, be filled with 2 kilograms of oxygen through gas feed pipe 2, the mixed emulsion of isobutyraldehyde and water (the content of isobutyraldehyde in the mixed solution is 50% by weight ) enters the liquid distributor 8 in the reactor 1 through the liquid feed pipe 2 through the feed pump 21; the circulation pump 31 pumps the gas in the upper part of the reactor 1 into the gas distributor 9 by the gas circulation line 7; the liquid distributor 8 The isobutyraldehyde-water mixture coming from the gas distributor 9 is driven by oxygen and sprayed into the reaction kettle 1 through the atomization unit 5 (specifically, the atomization nozzle) for rapid oxidation. The temperature in the reaction kettle 1 is 80°C and the pressure is 0.25°C. MPa, the reaction time is 2h. The liquid at the bottom of the reaction kettle 1 is discharged through the discharge pipe 4 for oil-water...

Embodiment 2

[0075] First, 8 kilograms of oxygen are charged into the reactor 1 through the gas feed pipe 2, and the mixed emulsion of isopropanal and water (the content of isobutyraldehyde in the mixed solution is 60% by weight) is passed through the feed pump 21 by the liquid feed pipe 2. Enter the liquid distributor 8 in the reactor 1; the circulation pump 31 pumps the upper gas in the reactor 1 into the gas distributor 9 through the gas circulation line 7; the isobutyraldehyde water coming from the liquid distributor 8 and the gas distributor 9 is mixed The liquid is driven by oxygen and sprayed into the reaction kettle 1 through the atomization unit 5 (specifically, the atomization nozzle) for rapid oxidation. The temperature in the reaction kettle 1 is 30° C., the pressure is 0.25 MPa, and the reaction time is 3 hours. The liquid at the bottom of the reaction kettle 1 is discharged through the discharge pipe 4 for oil-water separation, and the isobutyric acid contained in the water ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com