Reaction device for preparing isobutyric acid

A reaction device, the technology of isobutyric acid, applied in the direction of chemical/physical/physical chemical nozzle reactor, etc., can solve the problems of easy explosion and long reaction time, so as to improve the reaction speed, avoid explosion accidents, and reduce energy consumption. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

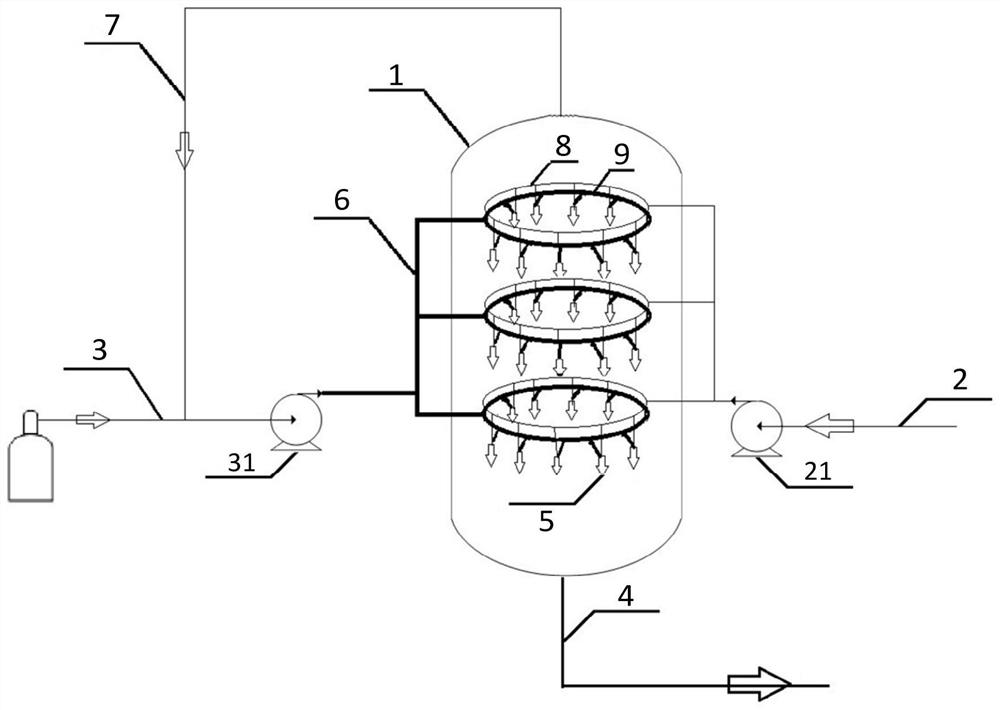

[0066] exist figure 1 Carry out the preparation of isobutyric acid in the shown device, at first in reactor 1, be filled with 2 kilograms of oxygen through gas feed pipe 2, the mixed emulsion of isobutyraldehyde and water (the content of isobutyraldehyde in the mixed solution is 50% by weight ) enters the liquid distributor 8 in the reactor 1 through the liquid feed pipe 2 through the feed pump 21; the circulation pump 31 pumps the gas in the upper part of the reactor 1 into the gas distributor 9 by the gas circulation line 7; the liquid distributor 8 The isobutyraldehyde-water mixture coming from the gas distributor 9 is driven by oxygen and sprayed into the reaction kettle 1 through the atomization unit 5 (specifically, the atomization nozzle) for rapid oxidation. The temperature in the reaction kettle 1 is 80°C and the pressure is 0.25°C. MPa, the reaction time is 2h. The liquid at the bottom of the reaction kettle 1 is discharged through the discharge pipe 4 for oil-water...

Embodiment 2

[0069] First, 8 kilograms of oxygen are charged into the reactor 1 through the gas feed pipe 2, and the mixed emulsion of isopropanal and water (the content of isobutyraldehyde in the mixed solution is 60% by weight) is passed through the feed pump 21 by the liquid feed pipe 2. Enter the liquid distributor 8 in the reactor 1; the circulation pump 31 pumps the upper gas in the reactor 1 into the gas distributor 9 through the gas circulation line 7; the isobutyraldehyde water coming from the liquid distributor 8 and the gas distributor 9 is mixed The liquid is driven by oxygen and sprayed into the reaction kettle 1 through the atomization unit 5 (specifically, the atomization nozzle) for rapid oxidation. The temperature in the reaction kettle 1 is 30° C., the pressure is 0.25 MPa, and the reaction time is 3 hours. The liquid at the bottom of the reaction kettle 1 is discharged through the discharge pipe 4 for oil-water separation, and the isobutyric acid contained in the water ph...

Embodiment 3

[0072] At first in reactor 1, be charged with 5 kilograms of oxygen through gas feed pipe 2, the mixed emulsion of isopropanal and water (the content of isobutyraldehyde in the mixed solution is 70% by weight) by liquid feed pipe 2 through feed pump 21 Enter the liquid distributor 8 in the reactor 1; the circulation pump 31 pumps the upper gas in the reactor 1 into the gas distributor 9 through the gas circulation line 7; the isobutyraldehyde water coming from the liquid distributor 8 and the gas distributor 9 is mixed The liquid is driven by oxygen and sprayed into the reaction kettle 1 through the atomization unit 5 (specifically, the atomization nozzle) for rapid oxidation. The temperature in the reaction kettle 1 is 50°C, the pressure is 0.4MPa, and the reaction time is 3h. The liquid at the bottom of the reaction kettle 1 is discharged through the discharge pipe 4 for oil-water separation, and the isobutyric acid contained in the water phase is further separated.

[0073]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com