A kind of aromatic and aliphatic chain co-brominated high molecular polymer and its preparation method

A high molecular polymer and aliphatic chain technology, which is applied in the field of flame retardant synthesis, can solve the problems of inaccurate bromination of products, low molecular weight, and high production energy consumption, and achieves simple and easy post-processing methods and raw material utilization. High, good product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

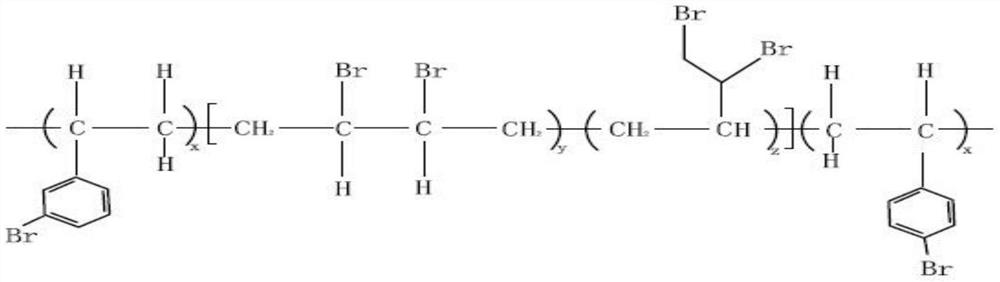

[0029] An aromatic and aliphatic chain co-brominated high molecular polymer, its structural formula is:

[0030]

[0031] The specific preparation method includes the following steps in turn:

[0032] (1) Fatty chain bromination: add 240g of methylene chloride and 30g of styrene butadiene polymer to a 1000ml four-necked bottle, stir and dissolve, and set aside for later use. 60g of dichloromethane, 70g of liquid bromine, and 90g of tetraethylammonium bromide were added to a 500ml four-necked bottle to prepare a solution of tetraethylammonium tribromide in dichloromethane, for subsequent use. The reaction temperature of the 1000ml four-necked flask was controlled to be 10°C, and the pre-prepared tetraethylammonium tribromide dichloromethane solution was poured into the styrene butadiene polymer solution to carry out bromination reaction for 10 hours. After the reaction was completed, 100 ml of water was added, and tetraethylammonium bromide was recovered by washing with wat...

Embodiment 2

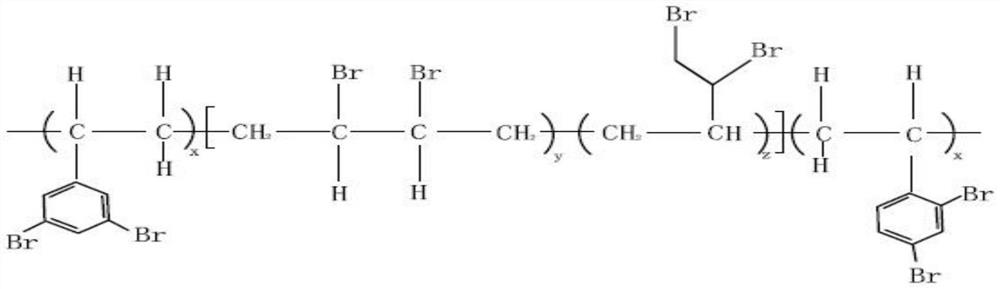

[0036] A kind of macromolecular polymerization of aromatic and aliphatic chains co-brominated, its structural formula is:

[0037]

[0038] The specific preparation method includes the following steps in turn:

[0039](1) Fatty chain bromination: add 210g of dichloroethane and 30g of styrene butadiene polymer into a 1000ml four-necked bottle, stir and dissolve, and set aside. 50g of dichloroethane, 70g of liquid bromine and 100g of tetrabutylammonium bromide were added to a 500ml four-necked bottle to prepare a solution of tetrabutylammonium tribromide in dichloroethane, for later use. The reaction temperature of the 1000ml four-necked flask was controlled to be 15°C, and the pre-prepared tetrabutylammonium tribromide dichloroethane solution was poured into the styrene butadiene polymer solution to carry out bromination reaction for 13 hours. After the reaction was completed, 100 ml of water was added, and tetrabutylammonium bromide was recovered by washing with water, and...

Embodiment 3

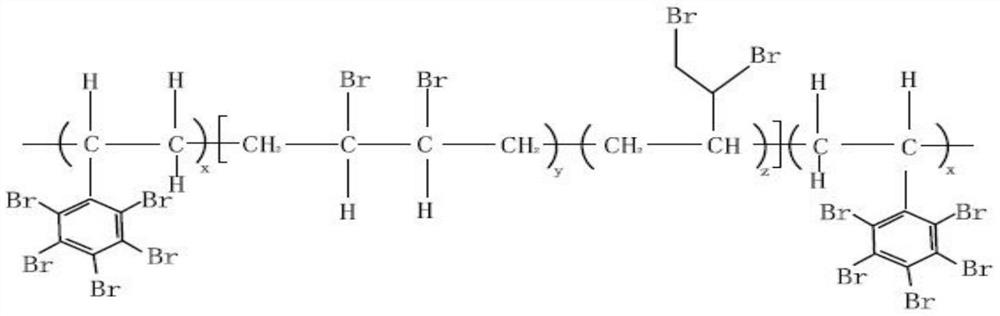

[0043] An aromatic and aliphatic chain co-brominated high molecular polymer, its structural formula is:

[0044]

[0045] The specific preparation method includes the following steps in turn:

[0046] (1) Fatty chain bromination: add 150g of chlorobenzene and 30g of styrene butadiene polymer into a 1000ml four-necked bottle, stir and dissolve, and set aside for later use. Add 50g of chlorobenzene, 70g of liquid bromine, and 53g of benzyltrimethylammonium bromide to a 500ml four-necked bottle, and prepare a solution of benzyltrimethylammonium tribromide in chlorobenzene, for subsequent use. The reaction temperature of the 1000ml four-necked flask was controlled to be 17°C, and the pre-prepared solution of benzyltrimethylammonium tribromide in chlorobenzene was poured into the styrene butadiene polymer solution to carry out bromination reaction for 13 hours. After the reaction was completed, 100 ml of water was added, and benzyl trimethyl ammonium bromide was recovered by wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com