Coal tar and raw coke oven gas integrated purification and separation device

A technology for purification, separation, and raw gas, which is applied in tar processing, tar processing by chemical method, petroleum industry, etc. It can solve the problems of inconvenient separation, sewage generation, sewage discharge and environmental pollution, and achieve the effect of preventing solution splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

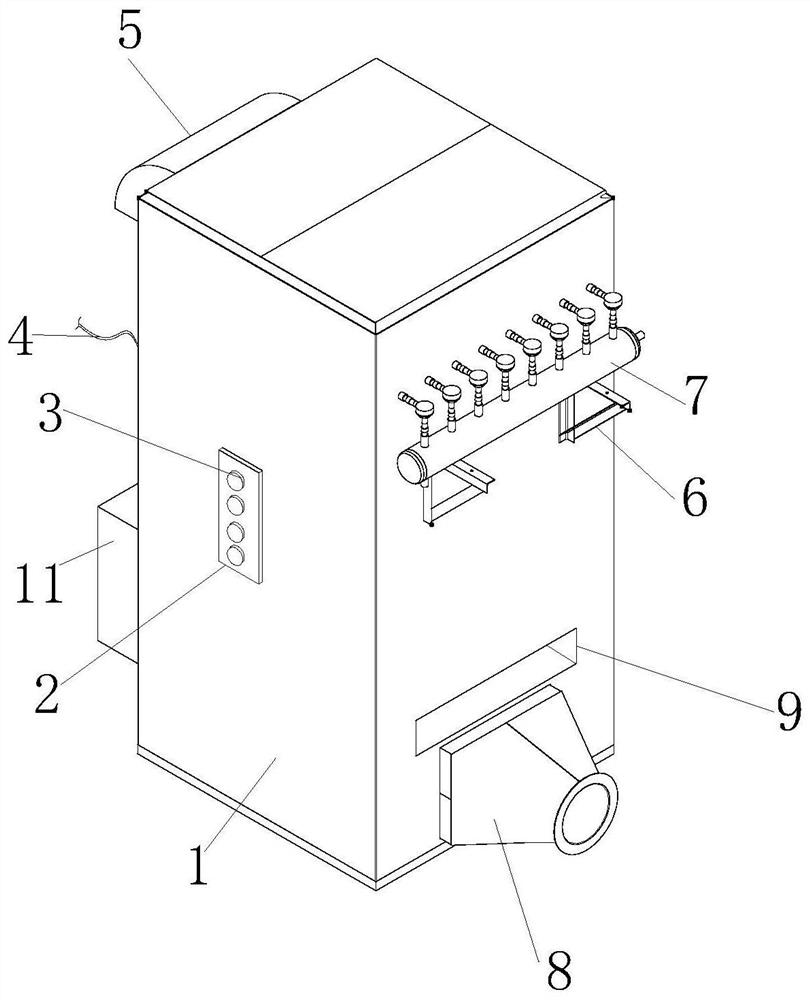

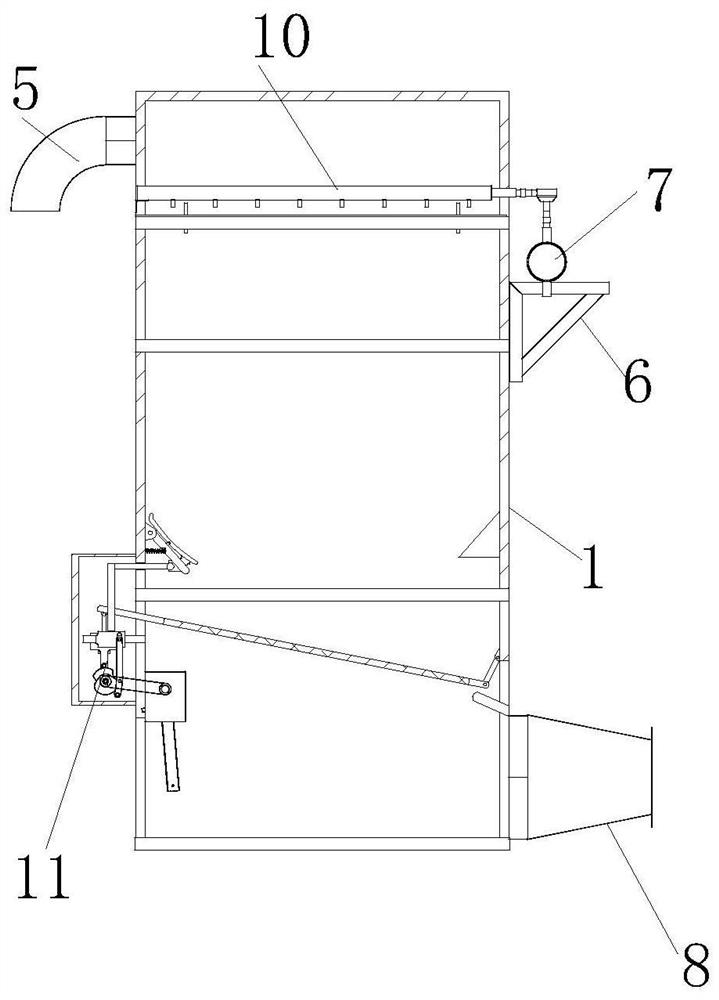

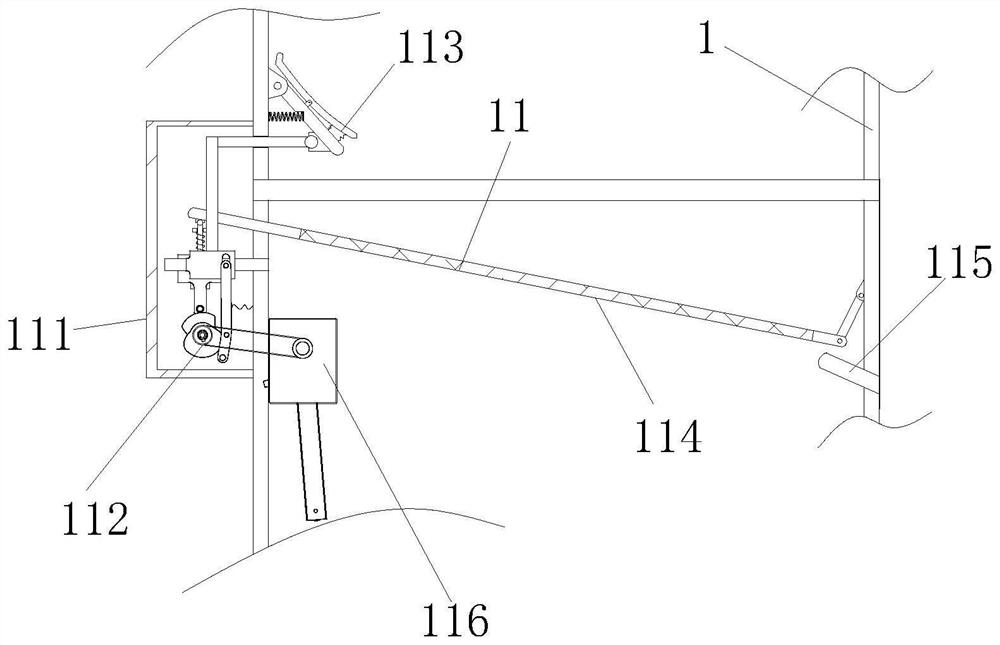

[0036] see figure 1 and figure 2 , the present invention provides an integrated purification and separation device for coal tar and raw coal gas through improvement, including a purification and separation frame 1, an air intake pipe 5, a support frame 6, a water collection pipe 7, a spray pipe 10 and a filter and oil removal mechanism 11, The front end of the purification separation frame 1 is provided with a control panel 2, the front end of the control panel 2 is equipped with a button 3, the left end of the purification separation frame 1 is fixed with a power lead 4, the filter and degreasing mechanism 11 is installed and fixed at the lower left end of the purification separation frame 1, and the purification separation frame 1 It communicates with the right end of the intake pipe 5, the purification separation frame 1 is welded and fixed to the left end of the support frame 6, the support frame 6 is fixedly connected to the bottom of the water collection pipe 7, the rig...

Embodiment 2

[0044] The present invention provides an integrated purification and separation device for coal tar and raw coal gas through improvement. The upper ends of the swing rod 1124 and the top rod 1129 are provided with a top wheel 11212, and the top wheel 11212 is connected with the right end of the first cam 1121 and the second cam respectively. The tops of 1128 are in contact with each other, which is conducive to driving the swing bar 1124 to swing and driving the push rod 1129 to move up. Push rod 1129 moves smoothly.

[0045] The present invention provides an integrated purification and separation device for coal tar and raw coal gas through improvement, and its working principle is as follows;

[0046] First, before use, place the coal tar and raw gas integrated purification and separation device horizontally, so that the purification and separation frame 1 can fix and support the device;

[0047] Second, when in use, connect the external power supply through the power suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com