Preparation method of palm oil-based environment-friendly concrete water-based release agent

An environmentally friendly concrete and palm oil technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems caused by the non-renewable environment of the raw material of concrete release agent, not resistant to rain erosion, damage, etc., and achieve excellent emulsification stability and space. Stability, easy to emulsify, improve the effect of emulsion adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

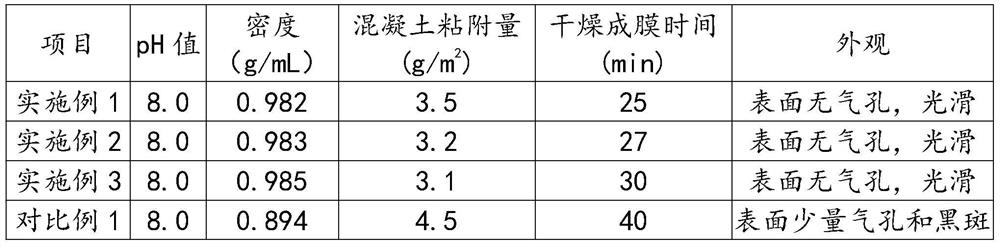

Examples

Embodiment 1

[0025] A kind of palm oil-based environment-friendly concrete aqueous release agent preparation method, comprises the steps:

[0026] The first step, weigh the following component raw materials in parts by weight: 38 parts of palm oil, 2 parts of water-soluble emulsifier, 2.5 parts of oily emulsifier, 1 part of emulsification aid, 2 parts of substrate wetting agent, 2 parts of waterproofing agent and 0.5 parts of antirust agent;

[0027] The second step, the emulsifier is pre-dispersed in palm oil: put the weighed palm oil into the reactor, and at the stirring speed of 200r / min, add the water-soluble emulsifier into the reactor until the mixed liquid in the reactor is dark. Stop stirring in yellow turbid state;

[0028] The third step, emulsion formation: under the conditions of dispersion speed of 1000r / min and temperature of 45°C, mix oil-soluble emulsifier, emulsification aid, substrate wetting agent, water repellent and rust inhibitor to make emulsified water, Add emulsi...

Embodiment 2

[0037] A kind of palm oil-based environment-friendly concrete aqueous release agent preparation method, comprises the steps:

[0038] The first step, weigh the following component raw materials in parts by weight: 44 parts of palm oil, 2.5 parts of water-soluble emulsifier, 3 parts of oily emulsifier, 1.5 parts of emulsification aid, 2.2 parts of substrate wetting agent, 2.2 parts of waterproofing agent and 0.7 parts of antirust agent;

[0039] The second step, the emulsifier is pre-dispersed in the palm oil: add the weighed palm oil into the reactor, and at the stirring speed of 250r / min, add the water-soluble emulsifier into the reactor until the mixed liquid in the reactor becomes dark. Stop stirring in yellow turbid state;

[0040]The third step, emulsion formation: under the conditions of dispersion speed of 1000r / min and temperature of 45°C, mix oil-soluble emulsifier, emulsification aid, substrate wetting agent, water repellent and rust inhibitor to make emulsified wat...

Embodiment 3

[0049] A kind of palm oil-based environment-friendly concrete aqueous release agent preparation method, comprises the steps:

[0050] The first step, weigh the following component raw materials by weight: 50 parts of palm oil, 3 parts of water-soluble emulsifier, 3.5 parts of oily emulsifier, 2 parts of emulsification aid, 2.5 parts of substrate wetting agent, 2.5 parts of waterproofing agent and 1 part of antirust agent;

[0051] The second step, the emulsifier is pre-dispersed in the palm oil: put the weighed palm oil into the reactor, and at the stirring speed of 300r / min, add the water-soluble emulsifier into the reactor until the mixed liquid in the reactor becomes dark. Stop stirring in yellow turbid state;

[0052] The third step, emulsion formation: under the conditions of dispersion speed of 1000r / min and temperature of 45°C, mix oil-soluble emulsifier, emulsification aid, substrate wetting agent, water repellent and rust inhibitor to make emulsified water, Add emul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com