Anti-cracking leather and production method thereof

An anti-cracking and leather technology, applied in textiles and papermaking, etc., can solve the problems of insufficient buckling resistance and reduced bonding strength of the adhesive layer, and achieve the effects of strong practicability, reduced peeling and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

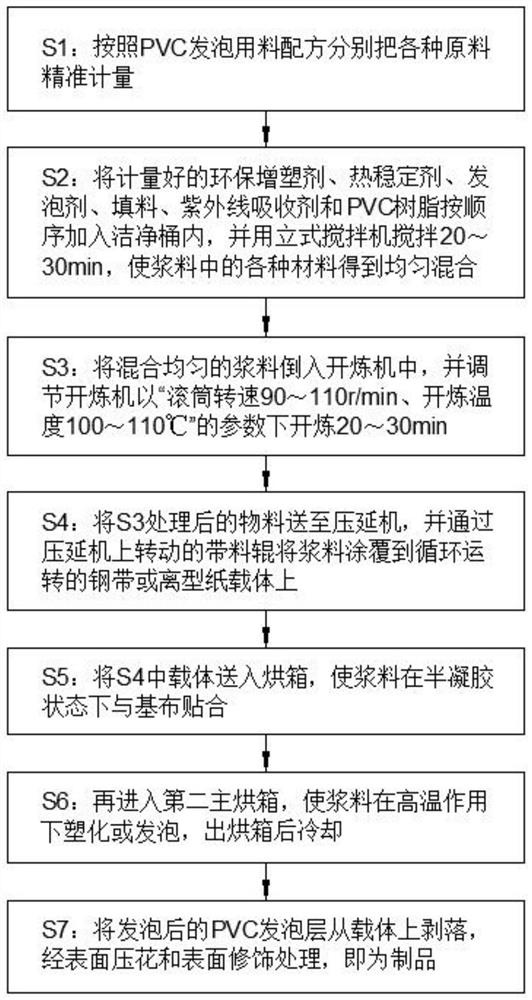

Image

Examples

Embodiment 1

[0024] A kind of anti-cracking leather of the present invention comprises a base cloth layer, a PVC foam layer and a surface modification layer, the PVC foam layer is arranged between the base cloth layer and the surface modification layer, and the PVC foam layer is specifically composed of The raw materials are composed of the following parts by weight: 110 parts of PVC resin, 80 parts of environmentally friendly plasticizer, 3 parts of heat stabilizer, 4 parts of foaming agent, 8 parts of filler, and 3 parts of ultraviolet absorber.

[0025] Wherein, the base fabric layer is any one of knitted fabric or woven fabric.

[0026] Wherein, the plasticizer is dioctyl phthalate or epoxy fatty acid methyl ester.

[0027] Wherein, the heat stabilizer is a barium-zinc composite heat stabilizer, and the type of the heat stabilizer that is a barium-zinc composite heat stabilizer is BF-470HB.

[0028] Wherein, the ultraviolet absorber is ultraviolet absorber UV-531, and the component is...

Embodiment 2

[0039] A kind of anti-cracking leather of the present invention comprises a base cloth layer, a PVC foam layer and a surface modification layer, the PVC foam layer is arranged between the base cloth layer and the surface modification layer, and the PVC foam layer is specifically composed of The raw materials are composed of the following parts by weight: 105 parts of PVC resin, 82 parts of environmentally friendly plasticizer, 3.4 parts of heat stabilizer, 4.5 parts of foaming agent, 9 parts of filler, and 3.5 parts of ultraviolet absorber.

[0040] Wherein, the base fabric layer is any one of knitted fabric or woven fabric.

[0041] Wherein, the plasticizer is dioctyl phthalate or epoxy fatty acid methyl ester.

[0042] Wherein, the heat stabilizer is a barium-zinc composite heat stabilizer, and the type of the heat stabilizer that is a barium-zinc composite heat stabilizer is BF-470HB.

[0043] Wherein, the ultraviolet absorber is ultraviolet absorber UV-531, and the compon...

Embodiment 3

[0054] A kind of anti-cracking leather of the present invention comprises a base cloth layer, a PVC foam layer and a surface modification layer, the PVC foam layer is arranged between the base cloth layer and the surface modification layer, and the PVC foam layer is specifically composed of The raw materials are composed of the following parts by weight: 120 parts of PVC resin, 85 parts of environmentally friendly plasticizer, 3.8 parts of heat stabilizer, 4.8 parts of foaming agent, 9.5 parts of filler, and 3.8 parts of ultraviolet absorber.

[0055] Wherein, the base fabric layer is any one of knitted fabric or woven fabric.

[0056] Wherein, the plasticizer is dioctyl phthalate or epoxy fatty acid methyl ester.

[0057] Wherein, the heat stabilizer is a barium-zinc composite heat stabilizer, and the type of the heat stabilizer that is a barium-zinc composite heat stabilizer is BF-470HB.

[0058] Wherein, the ultraviolet absorber is ultraviolet absorber UV-531, and the compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com