Improving acceleration of gas turbine

A technology of gas turbine and turbine, which is applied in the direction of fuel control of turbine/propulsion device, gas turbine device, turbine/propulsion fuel delivery system, etc., and can solve problems such as seldom referring to the optimal control strategy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

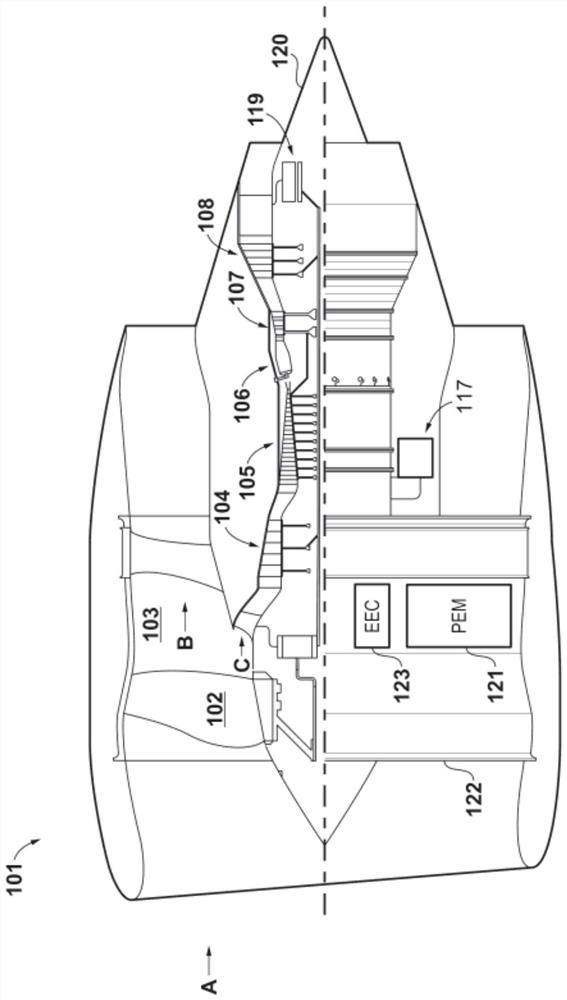

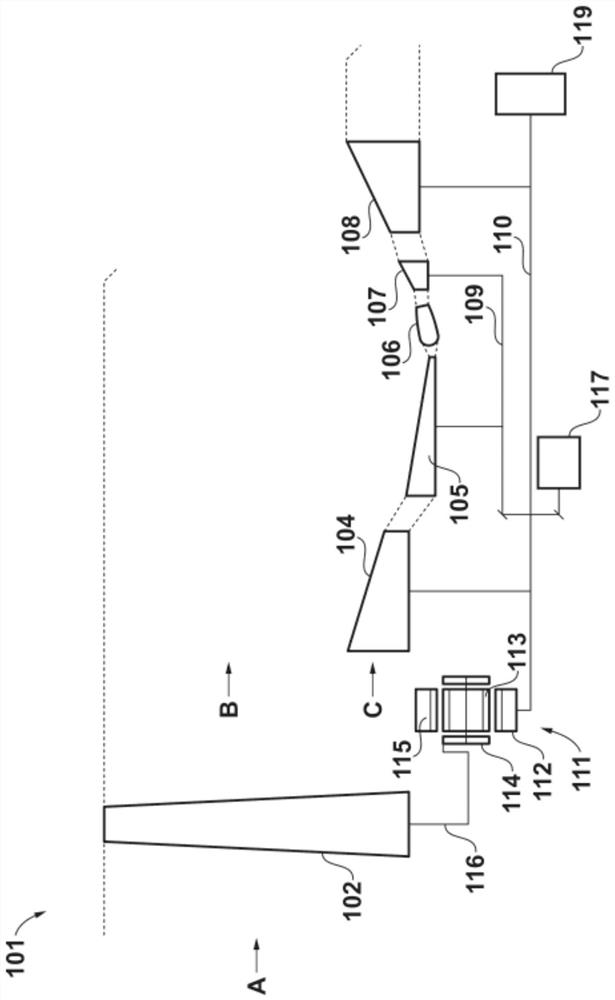

[0033] The invention is described in the context of a two-spool geared turbofan engine architecture. However, it will be apparent to those skilled in the art that the principles of the present invention can be applied to other engine types, including gas turbines having two or more slide valves, such as direct drive turbofans, turboprops, or open rotor engines .

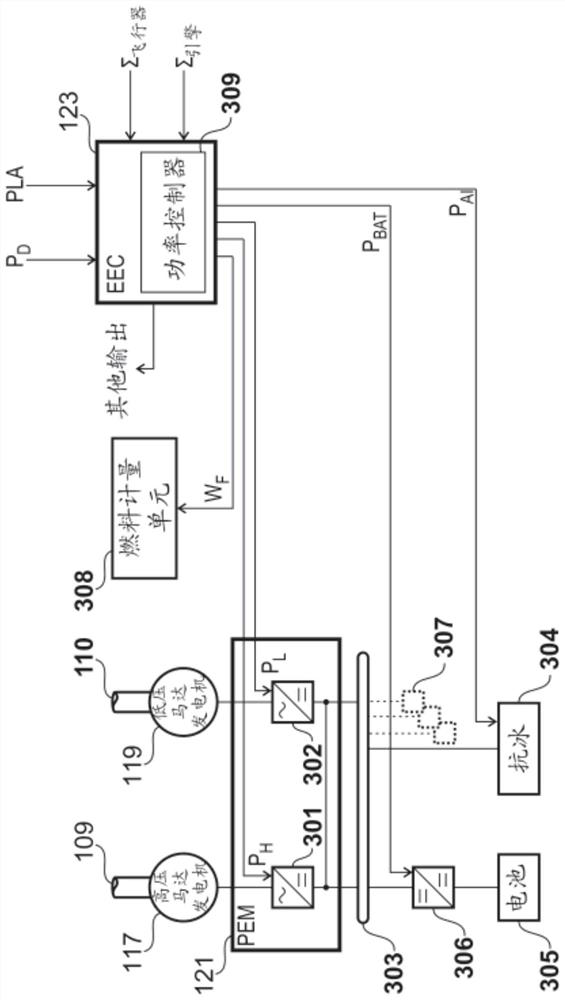

[0034] figure 1 and figure 2

[0035] The general arrangement structure of the engine 101 of aircraft is in figure 1 is shown in the equivalent block diagram of its main components in figure 2 shown in .

[0036] In this embodiment, the engine 101 is a turbofan and thus includes a ducted fan 102 which receives intake air A and generates two streams: a bypass flow B axially through a bypass duct 103 and a flow B into the core gas turbine. core flow C.

[0037] The core gas turbine includes a low pressure compressor 104 , a high pressure compressor 105 , a combustor 106 , a high pressure turbine 107 and a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com