A control system for controlling the ratio of hydrogen to carbon monoxide in the production of synthesis gas

A carbon monoxide and control system technology, applied in the direction of controlling the mixing ratio of fluids at different temperatures, gasification of granular/powdered fuels, etc., can solve problems such as prolonging the process flow, increasing process consumption, and excess hydrogen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

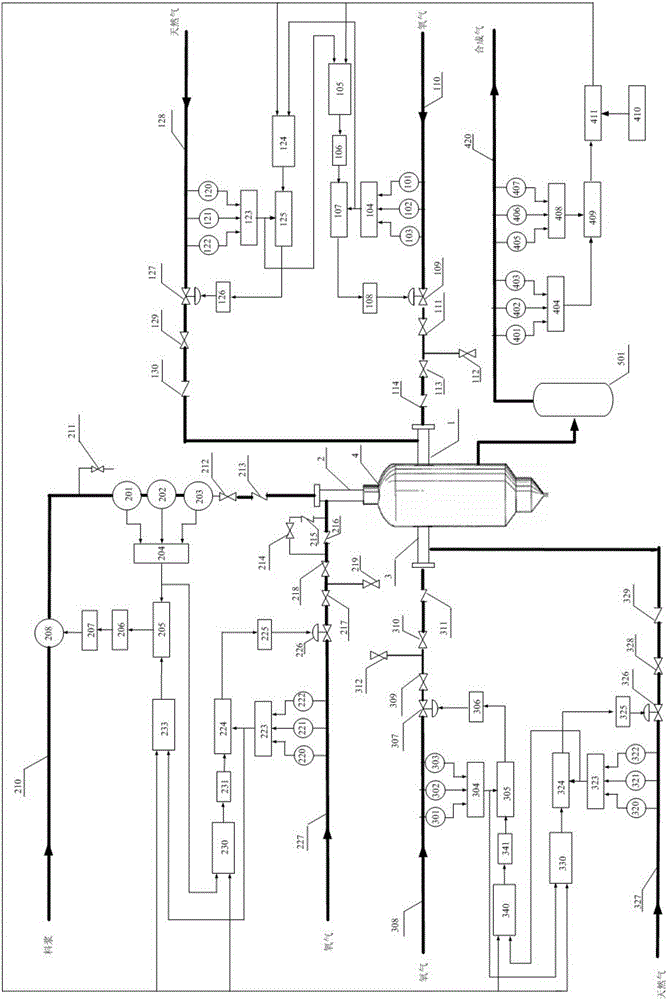

[0090] Embodiment 1: Adopt control system of the present invention to control synthesis gas production process

[0091] Using the method described in CN100593509C, a certain coal in Henan is used as raw material to produce synthesis gas, and the production conditions are as follows: the volume concentration of oxygen is 99.6%, and the flow rate of oxygen input gasification reactor is 31340.00Nm 3 / h, the pressure and temperature of the oxygen input boundary area are 8.3MPa, 40°C; the volume concentration of natural gas is 96.30%, and the flow rate of the input gasification reactor is 22744.40Nm 3 / h, the pressure and temperature of natural gas are 8.1MPa, 30℃; the slurry concentration is 65% based on the total weight of dry coal, the flow rate of slurry input gasification reactor is 41849.60kg / h, the pressure and temperature are 7.8 MPa, 40°C; gasification reactor operating pressure 6.50MPa, operating temperature 1350°C. Attached figure 1 The control system shown controls th...

Embodiment 2

[0120] Embodiment 2: Adopt control system of the present invention to control synthesis gas production process

[0121] Using the method described in CN100593509C, a certain coal in Henan is used as a raw material to produce synthesis gas, and the production conditions are as follows: the volume concentration of oxygen is 99.5%, and the flow rate of oxygen input into the gasification reactor is 29928.11Nm 3 / h, temperature and pressure are 40.00°C, 8.30MPa; the volume concentration of natural gas is 96.30%, and the flow rate of the gasification reactor is 26305.10Nm 3 / h, the temperature and pressure are 30.00°C and 8.10MPa respectively; the slurry concentration is 65% based on the total weight of dry coal, the flow rate of the slurry into the gasification reactor is 32521.26kg / h, and the temperature and pressure are respectively 50.00°C, 7.80MPa; the operating pressure of the gasification reactor is 6.50MPa, and the operating temperature is 1350°C.

[0122] Attached figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com