High-voltage vacuum circuit breaker mechanical fault diagnosis method and system

A technology for vacuum circuit breakers and mechanical faults, applied in circuit breaker testing, mechanical component testing, instruments, etc., can solve problems affecting the validity of feature quantities, fixed time-frequency resolution, and large computational load, and achieve accurate judgment. , quick identification, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention is described in further detail below in conjunction with accompanying drawing:

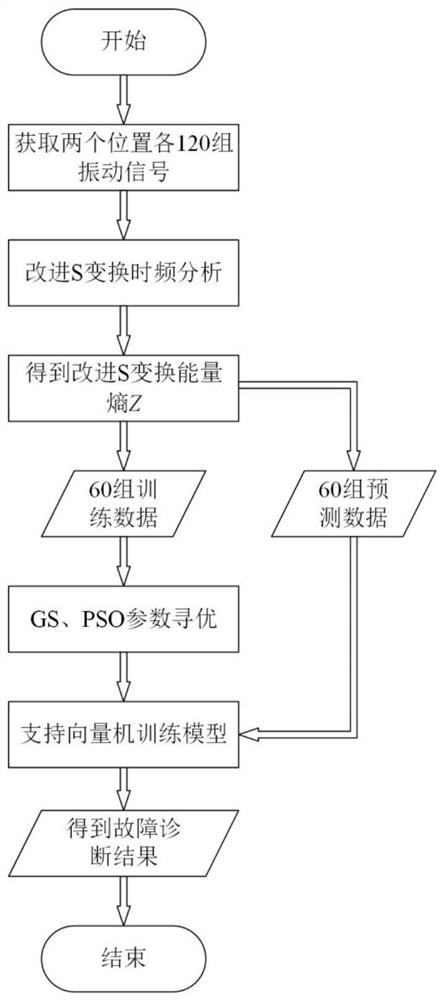

[0042] combine figure 1 The steps of a method for diagnosing a mechanical fault of a high-voltage vacuum circuit breaker according to the present invention are specifically described, including the following steps:

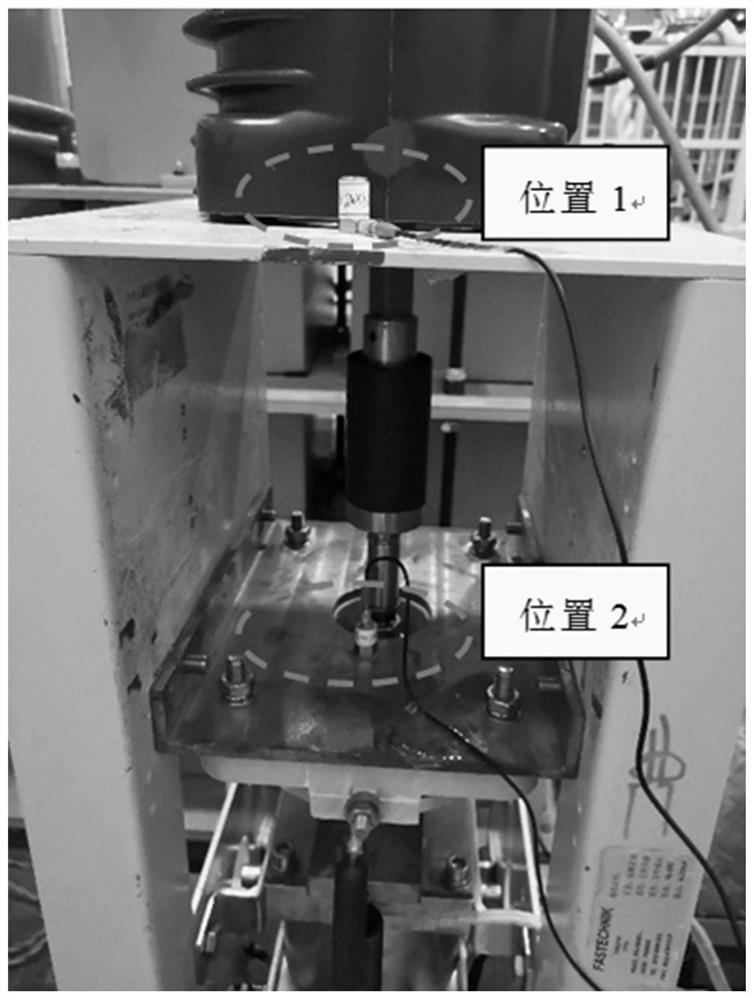

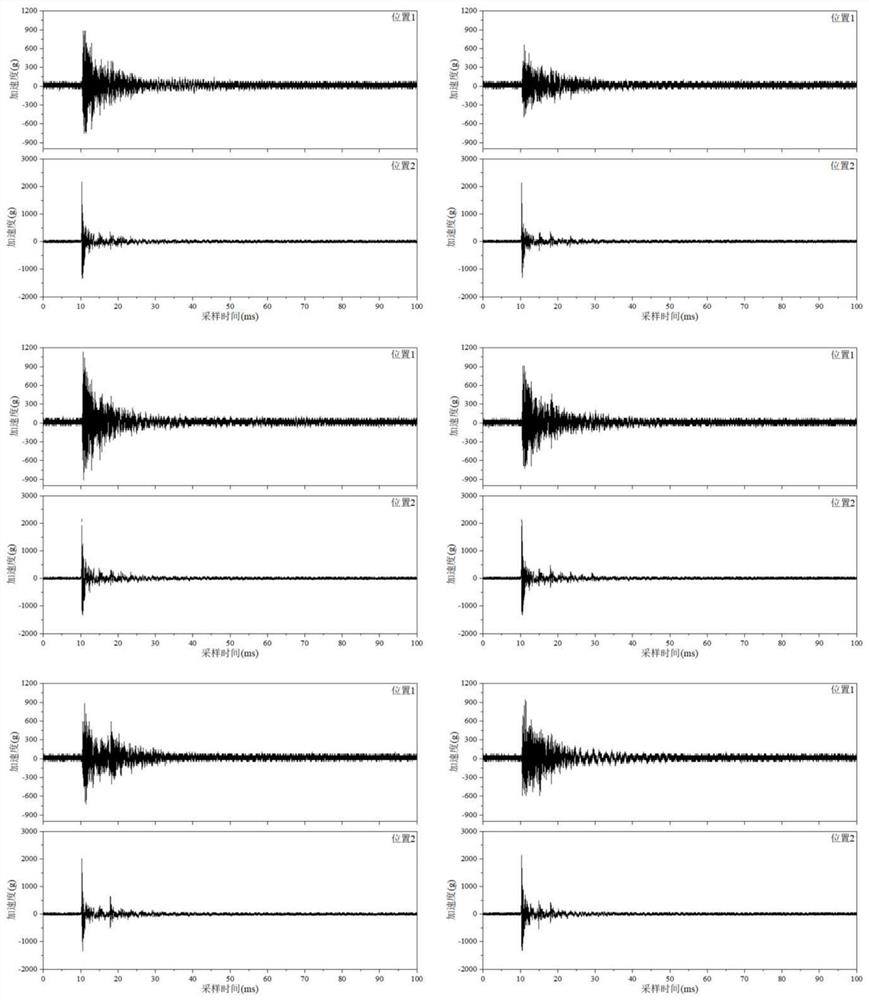

[0043] Step 1. Establish an experimental platform for a high-voltage vacuum circuit breaker with an electromagnetic repulsion mechanism, and simulate 5 kinds of faults, namely: fault 1-control circuit voltage is too low (85% of rated voltage), fault 2-control circuit voltage is too high (110% of rated voltage ), fault 3-increased resistance of the control loop (simulated coil aging), fault 4-buffer jamming, fault 5-base fixing screws loose. After comprehensively analyzing the vibration signals at different positions of the circuit breaker, select positions 1 and 2 to install acceleration sensors to collect vibration signals, such as figure 2 shown. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com