Automatic-discharging efficient recovery and extraction system for fragrance of plant extracting solution

A plant extract, automatic discharge technology, applied in grain processing, essential oils/spices, fat production, etc., can solve the problems of low work efficiency, poor automation, waste of labor, etc., and achieve convenient and fast use and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

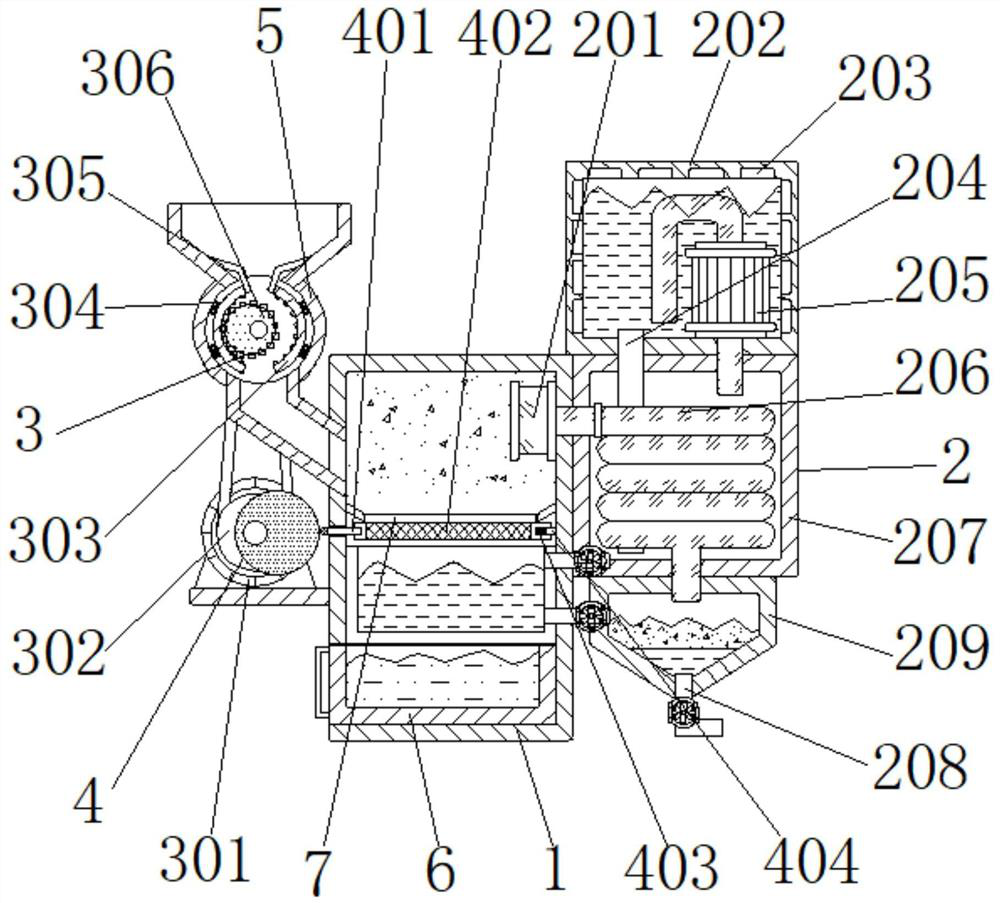

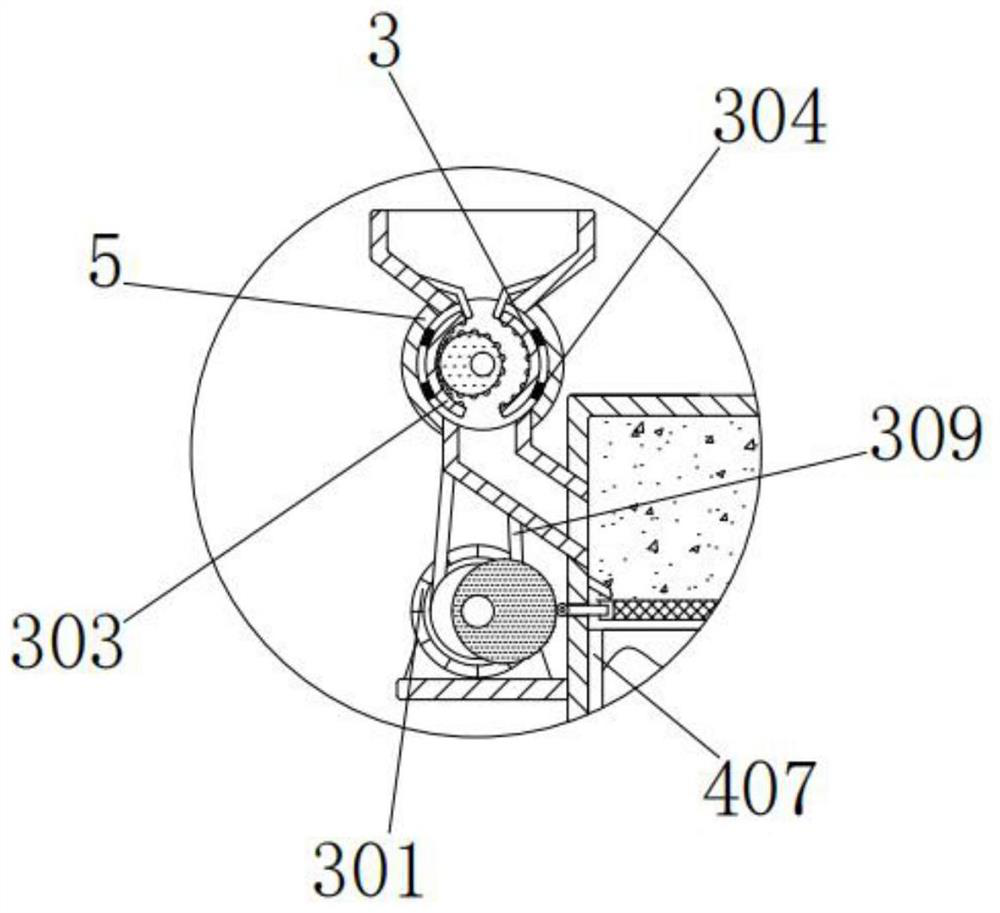

[0040]An automatic discharge plant extract liquid aroma efficient recovery extraction system, including a first box 1, the upper left side of the first box 1 is fixedly connected with a feed port 5, and the inner cavity of the feed port 5 is provided with a crushing device 3. The crushing device 3 includes a motor 301, a first sheave 302, a first curved plate 303, a first spring 304, a second curved plate 305, a round roller 306, a horizontal plate 307, a round shaft 308, a belt 309 and a second groove The wheel 310 and the right end of the horizontal plate 307 are fixedly connected to the lower left side of the first box body 1, the top of the horizontal plate 307 is fixedly connected with a motor 301, the model of the motor 301 is RS550SH-7527, and the output end of the motor 301 is fixedly connected with a A sheave 302, the top of the first sheave 302 is provided with a second sheave 310, the outer wall of the first sheave 302 is connected with the outer wall of the second s...

Embodiment 2

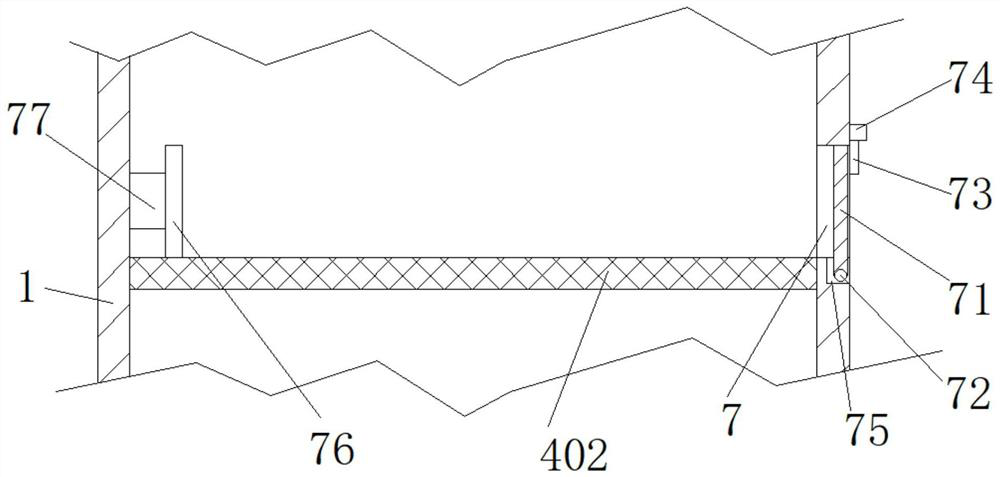

[0042] As an option, see figure 1 , 2 And 6, the automatic discharge plant extract aroma efficient recovery extraction system, the inner cavity of the first box body 1 is provided with a vibration device 4, and the vibration device 4 includes a short rod 401, a filter screen 402, a second spring 403, and a round rod 404 , circular plate 405, sphere 406 and the third casing 407, the rear end face of circular plate 405 is fixedly connected with the front end face of first sheave 302, and first sheave 302 can drive circular plate 405 to rotate simultaneously when first sheave 302 is stressed, and circular plate The right end of 405 fits with the left end of sphere 406, and the front end of sphere 406 is connected with the left side of the front end surface of short rod 401 through the pin shaft, and the outer wall of short rod 401 is matched with the inner wall of the first box body 1, and the short rod 401 The right end of the filter screen 402 is fixedly connected with a filte...

Embodiment 3

[0050] As an option, see figure 1 , automatic discharge plant extract aroma efficient recovery extraction system, the right side of the first box 1 is provided with a condensing device 2, the condensing device 2 includes a fan 201, a fourth box 202, a cooling plate 203, a round pipe 204, a water pump 205, curved pipe 206, fifth box body 207, short pipe 208 and sixth box body 209, the right end of fan 201 is fixedly connected with the upper right side of the inner wall of the first box body 1, the model of fan 201 is GD30K2-12, the fan The air outlet of 201 is fixedly connected with a curved pipe 206, the curved pipe 206 runs through the right side of the outer wall of the first box body 1 and the left side of the outer wall of the fifth box body 207, and the left side of the fifth box body 207 and the side of the first box body 1 The upper right side is fixedly connected, the first box body 1 plays a supporting role for the fifth box body 207, the bottom outer wall of the curv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com