Improved daylighting panel and preparation method thereof

A lighting panel and an improved technology, applied in chemical instruments and methods, flat products, other household appliances, etc., can solve the problems of insufficient flame retardancy, large power consumption, skin damage, etc. of the lighting panel, and achieve low cost and energy saving. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0035] 1) Take 50% unsaturated polyester resin, 2% flame retardant, 2.5% antioxidant, 2% accelerator, 8% infrared blocker, and 8% ultraviolet blocker according to the proportion of the formula and add it to the mixer and stir until it is completely uniform Then add 2.5% curing agent and mix evenly to obtain a resin mixture;

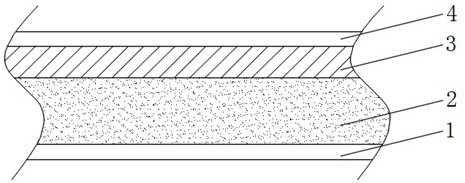

[0036] 2) Evenly coat a layer of gel coat on the PET lower film with a thickness of 150μm, and then add 25% reinforced glass fiber into the resin mixture evenly to mix the reinforced glass fiber and resin evenly, and then add the reinforced glass fiber The mixture of fibers and resin flows onto the PET lower film to form a resin layer with a thickness of 4mm;

[0037] 3) Uniformly coat a layer of gel coat on the solar film with a thickness of 150 μm. After heating the gel in a gel coat furnace, press it onto the resin layer to obtain the product;

[0038] 4) Send the finished product into the molding heating control area, and uniformly heat up to 180-200...

specific Embodiment 2

[0041] 1) Take 50% unsaturated polyester resin, 2% flame retardant, 2% antioxidant, 2% accelerator, 6% infrared blocker, and 6% ultraviolet blocker according to the proportion of the formula and add it to the mixer and stir until it is completely uniform Then add 2% curing agent and mix evenly to obtain a resin mixture;

[0042] 2) Evenly coat a layer of gel coat on the PET lower film with a thickness of 150μm, and then add 30% reinforced glass fiber into the resin mixture evenly to mix the reinforced glass fiber and resin evenly, and then add the reinforced glass fiber The mixture of fibers and resin flows onto the PET lower film to form a resin layer with a thickness of 4mm;

[0043] 3) Uniformly coat a layer of gel coat on the solar film with a thickness of 150 μm. After heating the gel in a gel coat furnace, press it onto the resin layer to obtain the product;

[0044] 4) Send the finished product into the molding heating control area, and uniformly heat up to 180-200°C a...

specific Embodiment 3

[0047] 1) Take 60% unsaturated polyester resin, 2% flame retardant, 2.5% antioxidant, 2% accelerator, 6.5% infrared blocker, 6.5% ultraviolet blocker and stir in the mixer according to the proportion of the formula, until it is completely uniform Then add 2.5% curing agent and mix evenly to obtain a resin mixture;

[0048] 2) Evenly coat a layer of gel coat on the PET lower film with a thickness of 150μm, and then add 18% reinforced glass fiber evenly into the resin mixture to mix the reinforced glass fiber and resin evenly, and then add the reinforced glass fiber The mixture of fibers and resin flows onto the PET lower film to form a resin layer with a thickness of 4mm;

[0049] 3) Uniformly coat a layer of gel coat on the solar film with a thickness of 150 μm. After heating the gel in a gel coat furnace, press it onto the resin layer to obtain the product;

[0050] 4) Send the finished product into the molding heating control area, and uniformly heat up to 180-200°C at a he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com