Manufacturing process of firewood-fired Jianzhan

A production process and wood-burning technology, applied in clay products, applications, household appliances, etc., can solve the problems of uneven temperature, lack of glaze layer, monotony, etc., to achieve less deformation and blistering defects, enrich daily life, craftsmanship Process clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

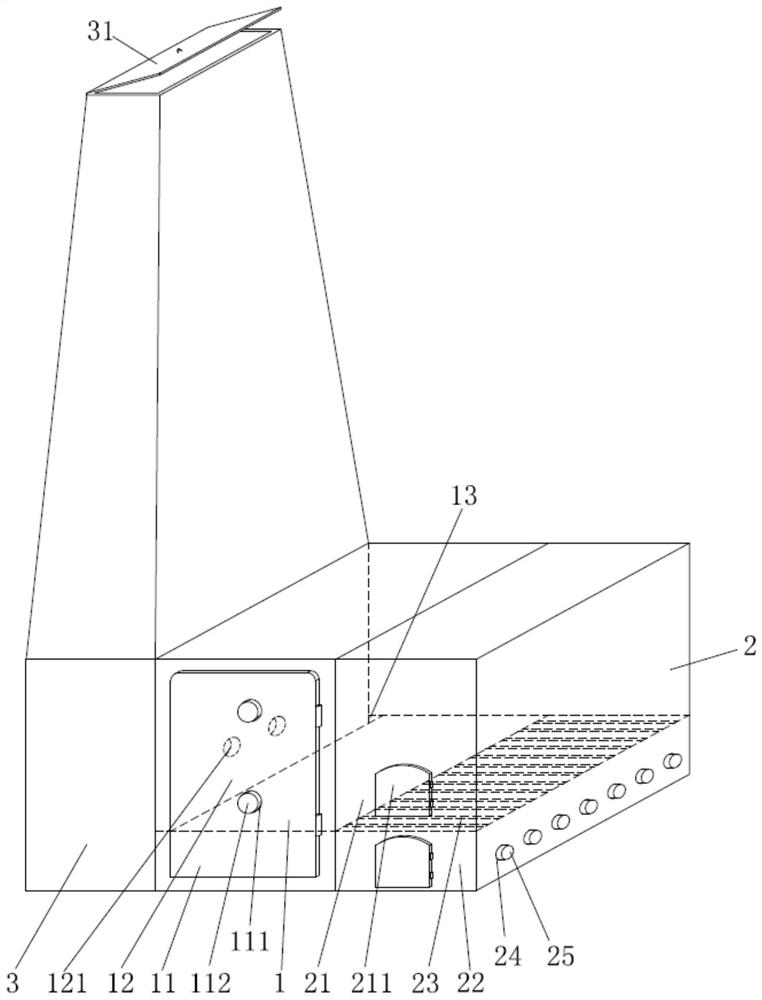

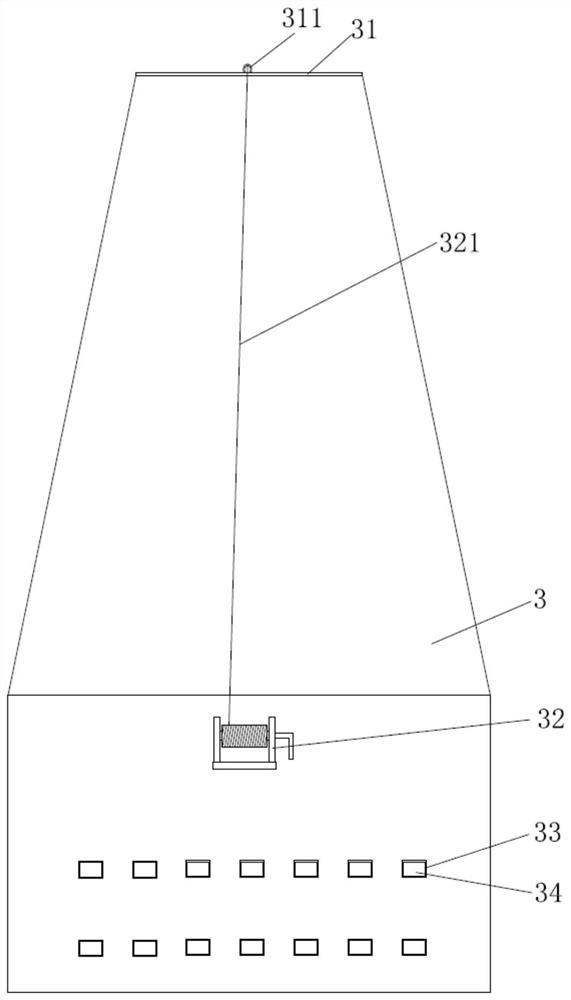

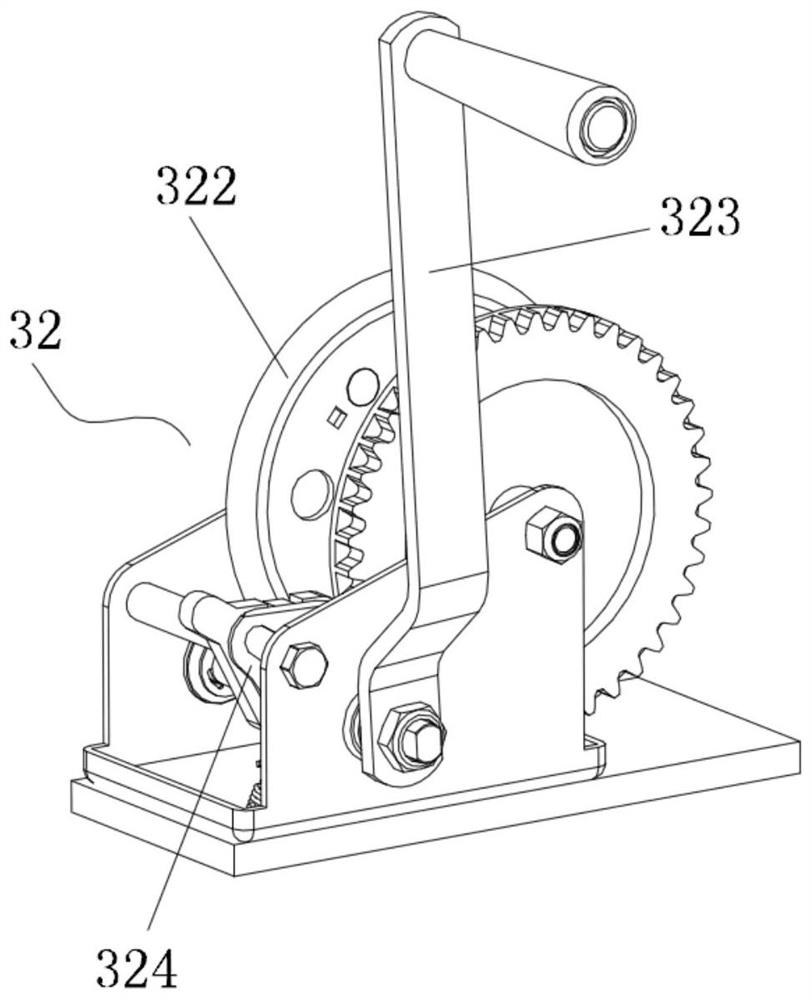

[0050] Please refer to figure 1 and figure 2 As shown, the present invention discloses a kiln for firing kilns, including a blank kiln chamber 1, a furnace 2 and a chimney 3, and the blank kiln chamber 1 is provided with a kiln door 11. The kiln door 11 is provided with at least one observation port 111 , and the observation port 111 is provided with a third pull-out plug 112 .

[0051] The billet kiln chamber 1 is located in the middle, and the furnace 2 and the chimney 3 are located on both sides of the billet kiln chamber 1 respectively.

[0052] The furnace 2 is divided into a combustion chamber 21 and an ash collection chamber 22 up and down by a grid 23; the combustion chamber 21 communicates with the billet kiln chamber 1. The combustion chamber 21 is provided with a furnace door 211;

[0053] A partition wall 12 is provided between the chimney 3 and the billet kiln chamber 1, and the bottom surface of the billet kiln chamber 1 is provided with a strip-shaped flue g...

Embodiment 2

[0066] The manufacturing process of wood-burning Jianzhan includes the following steps:

[0067] (1) preparing green body and glaze slurry;

[0068] Houjing red soil, Dali red soil, Nanshan clay, and Shuiyoshida mud are spread out to dry respectively, and pulverized, and then 75 parts by weight of Houjing red soil, 10 parts by weight of Dali red soil, 10 parts by weight of Nanshan clay, and 5 parts by weight of Shuiyoshitian mud Parts are mixed and washed with water; a part is passed through a 40-mesh sieve to obtain coarse mud, and another part is passed through a 60-mesh sieve to obtain fine mud, and then the coarse mud and fine mud are mixed in equal weight, stale, press-filtered, smelted, Knead the mud and pull the billet to form a green body, dry it, then trim the billet to shape, dry it again and then biscuit to obtain the green body;

[0069] Take the glaze ore and pulverize it, add an equal amount of water balls to grind it into a slurry, and pass through a 100-mesh s...

Embodiment 3

[0080] The manufacturing process of wood-burning Jianzhan includes the following steps:

[0081] (1) preparing green body and glaze slurry;

[0082] Houjing red soil, Dali red soil, Nanshan clay, and Shuiyoshida mud are spread out to dry respectively, and pulverized, and then 75 parts by weight of Houjing red soil, 10 parts by weight of Dali red soil, 10 parts by weight of Nanshan clay, and 5 parts by weight of Shuiyoshitian mud Parts are mixed and washed with water; a part is passed through a 40-mesh sieve to obtain coarse mud, and another part is passed through a 60-mesh sieve to obtain fine mud, and then the coarse mud and fine mud are mixed in equal weight, stale, press-filtered, smelted, Knead the mud and pull the billet to form a green body, dry it, then trim the billet to shape, dry it again and then biscuit to obtain the green body;

[0083] Take the glaze ore and pulverize it, add an equal amount of water polo to grind it into a slurry, and pass through a 100-mesh si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com