Method for removing silicon and phosphorus from blank roasting-ammonia leaching vanadium extracting solution

A blank roasting and ammonia leaching technology, applied in the direction of improving process efficiency, can solve the problems of incomplete silicon removal by silicon remover, increase vanadium loss, difficult to clarify vanadium liquid, etc., and achieve good environmental and economic benefits and vanadium loss. The effect of lowering and lowering production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] The embodiment of the present invention provides a method for removing silicon and phosphorus by blank roasting-ammonia leaching vanadium solution:

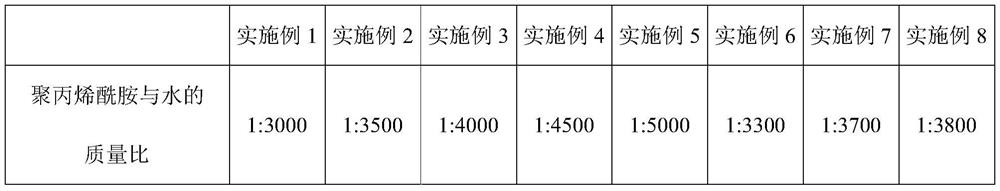

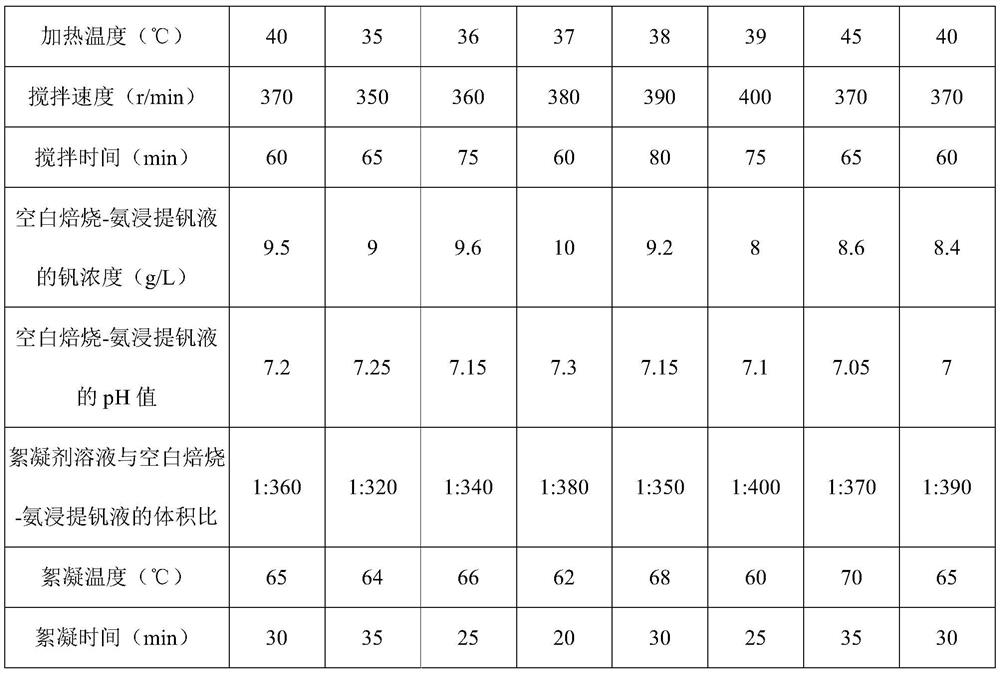

[0019] Mix polyacrylamide and water at a mass ratio of 1:3000-5000, heat to 35-45°C, and stir at a stirring speed of 350-400r / min for 40-80min to obtain an aqueous solution of polyacrylamide.

[0020] Control the vanadium concentration of blank roasting-ammonia leaching vanadium solution (silicon content is 131ppm, phosphorus content is 36ppm) to 8-10g / L, pH value is 7-7.3, and the prepared polyacrylamide aqueous solution is added to the blank roasting -In the ammonia leaching vanadium solution, the volume ratio of the flocculant solution to the blank roasting-ammonia leaching vanadium solution is 1:320~400, flocculate and settle at 60~70°C for 20~40min, and then use a fine filter Solid-liquid separation. The specific numerical values of each embodiment are shown in Table 1.

[0021] Table 1

[0022]

[0023]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com