Electrochemical hydrogen pump for preparing high-pressure hydrogen

A high-pressure hydrogen and electrochemical technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of low efficiency, high noise, high energy consumption, and achieve the effect of reducing cost, no noise, and high boosting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

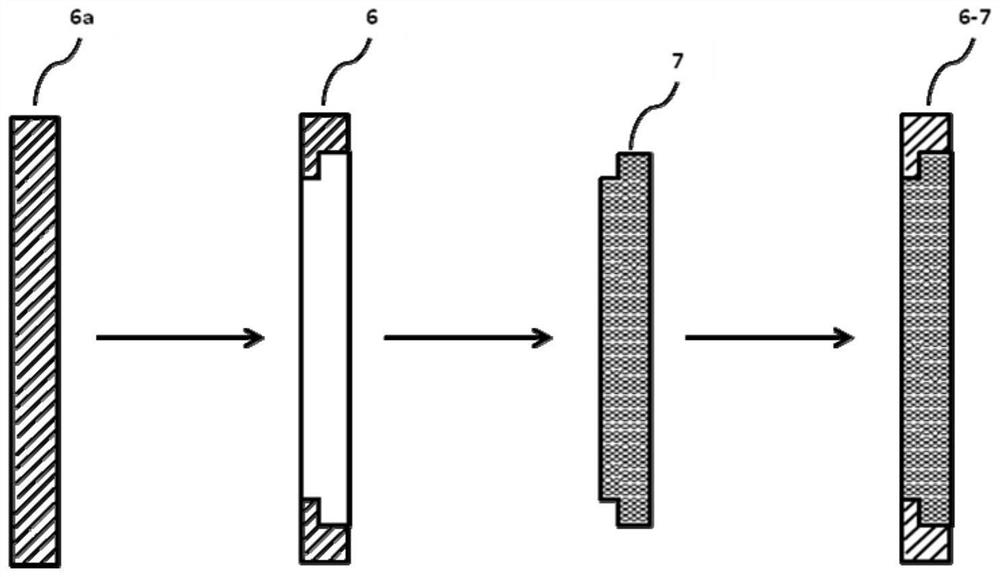

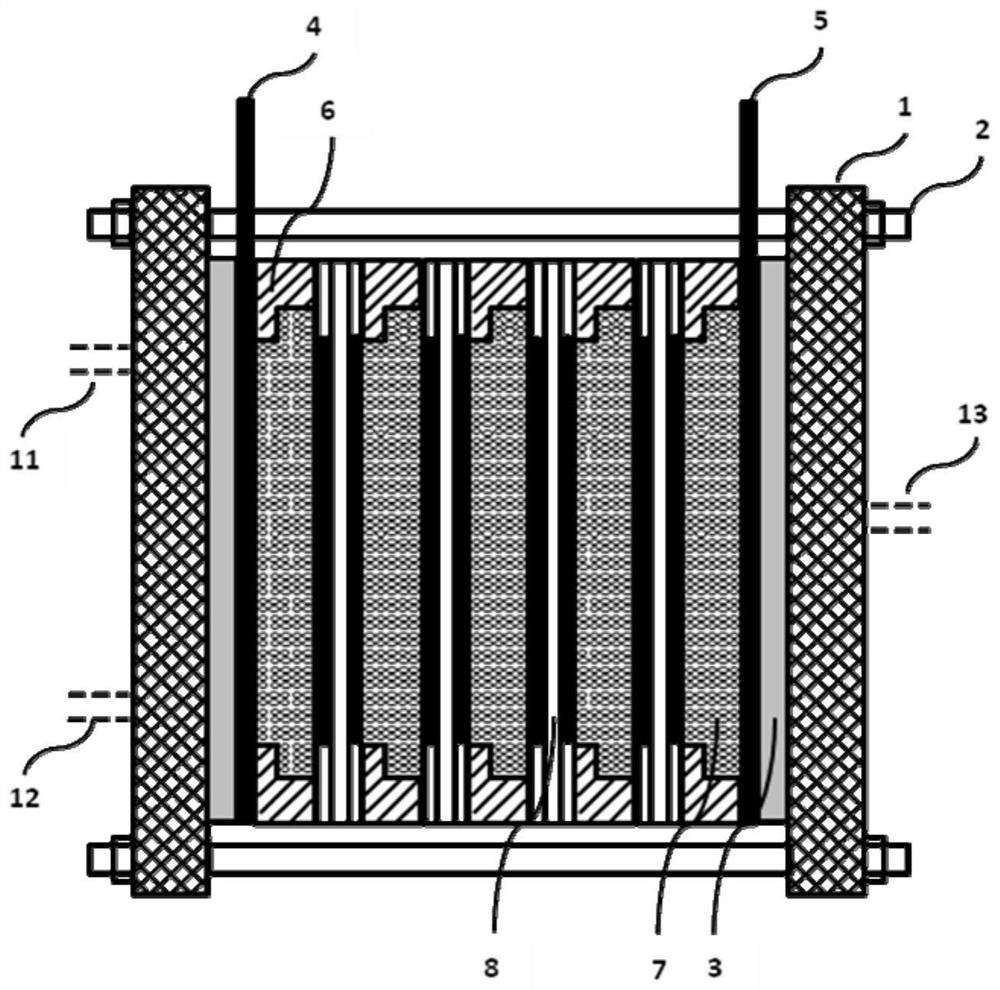

[0050] Such as figure 1 and figure 2 As shown, a low-pressure hydrogen gas inlet 11 and a low-pressure hydrogen gas outlet 12 are processed on one side of the fastening end plate 1, insulating plate 3 and positive electrode plate 4, and on the other side, the fastening end plate 1, insulating plate 3 and negative electrode plate 5 Process the high-pressure hydrogen outlet 13. Sealing is done between the fastening end plate 1 and the insulating plate 3, between the insulating plate 3 and the electrode plates 4 and 5, between the positive plate 4, the negative plate 5 and the separating and fixing plate 6. Select the separation and fixing plate original plate 6a that is consistent with the thickness of the gas-liquid transmission plate 7, and process the shape 6 with a built-in step, and process the gas-liquid transmission plate into a corresponding boss shape 7, such as figure 1 As shown, the separation and fixing plate-gas-liquid transmission plate assembly formed by the co...

Embodiment 2

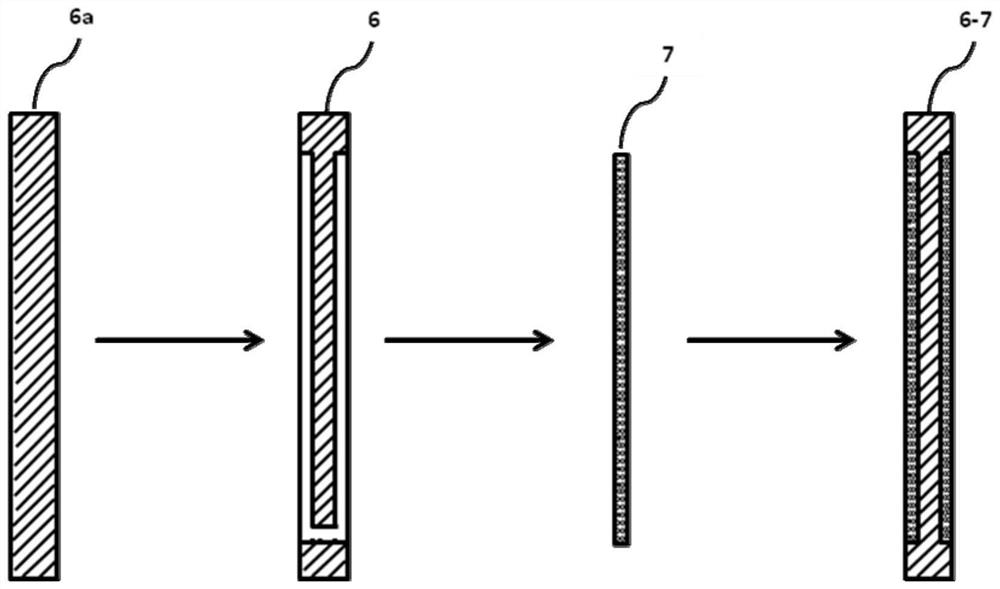

[0054] Such as image 3 and Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the air chamber components 6-7 are different. In this embodiment, the original plate 6a of the partition and fixing plate is selected, recesses 6 are processed on both sides of the partition and fixing plate, through holes 9 and 10 are processed on the partition and fixing plate, and the gas-liquid transmission plate is processed and embedded in the partition and fixing plate in the recessed platform. When a multi-stage hydrogen pump is used and multiple partitions and fixed plates are used, the gas-liquid channels processed on adjacent partitioned fixed plates should be staggered so that the gas and liquid can fully flow. Under the premise of ensuring good support, there can be one or more gas-liquid channels.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com