Ironing machine cleaning system and control method thereof

A cleaning system and ironing machine technology, applied in the field of ironing, can solve the problems of weakened heating effect, prolonged heating time, poor ironing effect, etc., so as to improve the descaling effect, improve the service life, and improve the ironing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

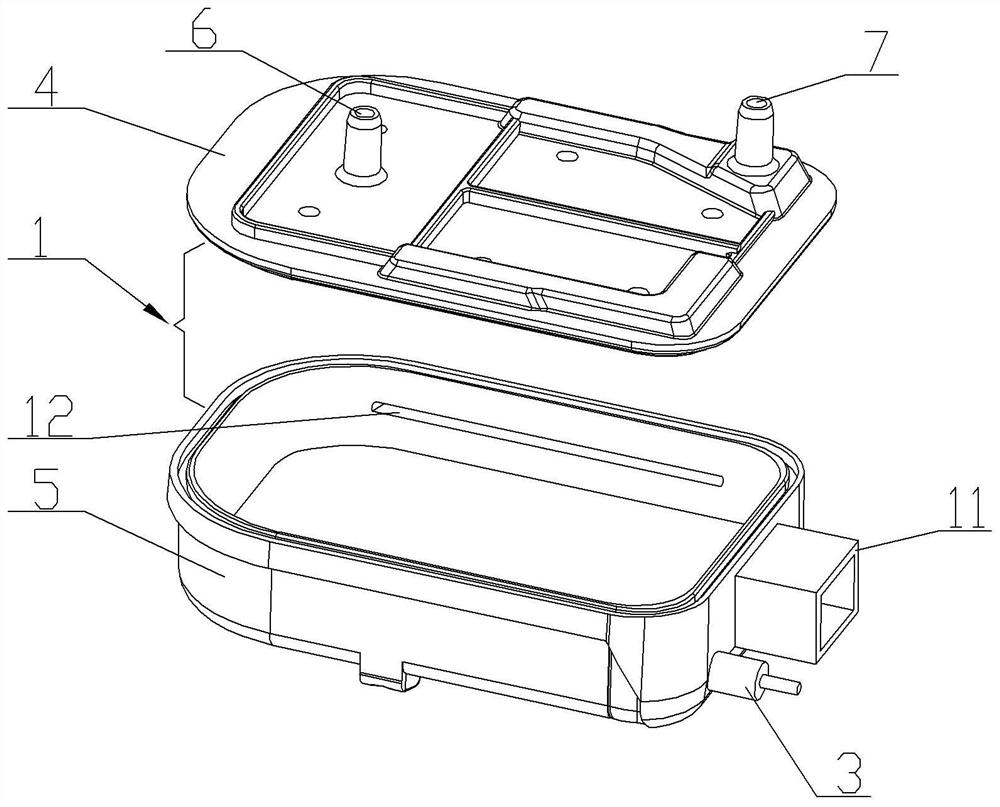

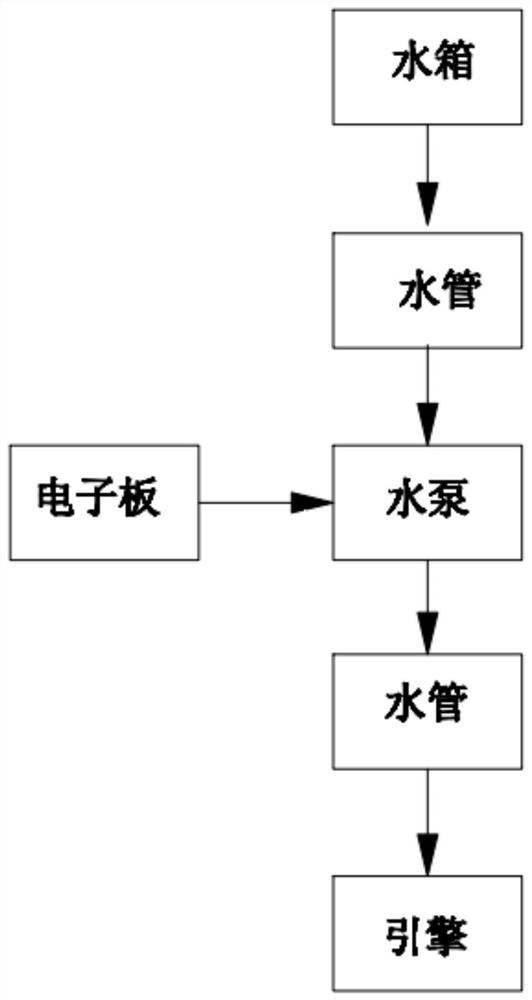

[0035] Embodiment one is basically as attached Figure 1-5 Shown: as figure 1 The cleaning system of an ironing machine shown includes an ironing machine body 1, an electronic board 2, a water pump, a water tank, a water pipe, and an engine 3. The ironing machine body 1 includes an upper cover 4 and a lower casing 5, and the upper cover 4 There are water inlet holes 6 and steam outlet holes 7 at the left and right ends of the engine respectively; the engine 3 includes heat pipes, which are embedded in the bottom of the lower casing 5 by die-casting technology, and the heat pipes can be Jshg type U-shaped pipes, and the heat pipes can be Connect to household power supply by wire.

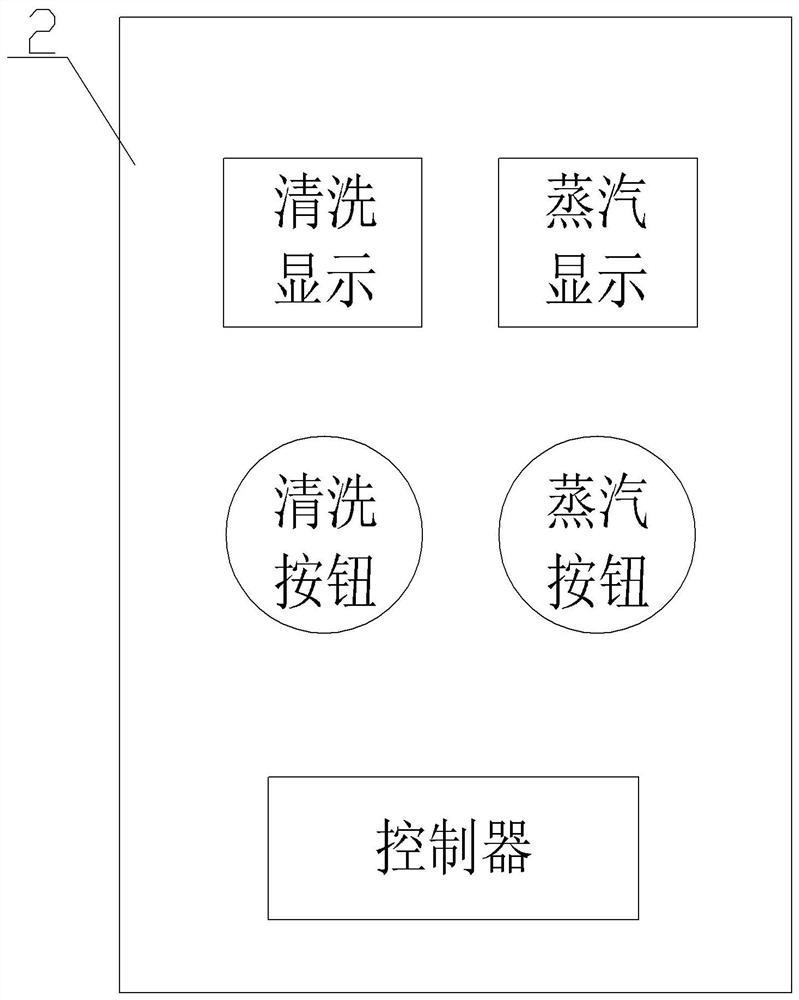

[0036] The electronic board 2 and the water tank are installed on the outside of the lower housing 5, and the water pump is installed on the water pipe between the water tank and the water inlet 6. like image 3 As shown, the electronic board 2 includes a cleaning display, a cleaning button, a ste...

Embodiment 2

[0043] On the basis of Example 1, as Figure 4 As shown, the cleaning system also includes a cleaning mechanism. The cleaning mechanism includes a servo motor 8, a screw 9 and a descaling block 10. A frame 11 with openings at both ends is welded on the body 1 of the ironing machine. The servo motor 8 is fixed on the iron body 1 by bolts. In the frame 11, the model of the servo motor 8 can be MR-J2S-100A; the screw 9 is located in the ironing machine body 1, the right end of the screw 9 is welded to the output shaft of the servo motor 8, and the left end of the screw 9 is connected to the lower casing 5 The side wall rotation connection.

[0044] Have threaded hole on the descaling block 10, and the descaling block 10 is threadedly connected with screw rod 9 by threaded hole; Figure 5 As shown, the inner wall of the lower housing 5 is provided with a "convex"-shaped slideway 12, the slideway 12 includes a limiting groove 13 and a flow groove 14; a block is welded on the desca...

Embodiment 3

[0054] Different from Embodiments 1 and 2, the cleaning system in this embodiment includes an ironing machine body 1, a water pump, a water tank, a water pipe, an engine 3 and a cleaning mechanism. The setting method is the same as in the first and second embodiments. The working steps are to manually start the water pump first, then pump water for 1 min, and then the heating pipe, the water pump and the cleaning mechanism work at the same time for 2 minutes. After the heat pipe works alone for 1min, the cleaning process is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com