Novel hot air type heating equipment based on old asphalt road surface heat regeneration

A heating equipment and heat regeneration technology, applied in the direction of roads, roads, road repair, etc., can solve the problems of easy damage of microwave heating components, hidden dangers, adhesion to the air outlet, etc., so as to protect from being blocked and reduce hidden dangers. , the effect of speeding up the heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

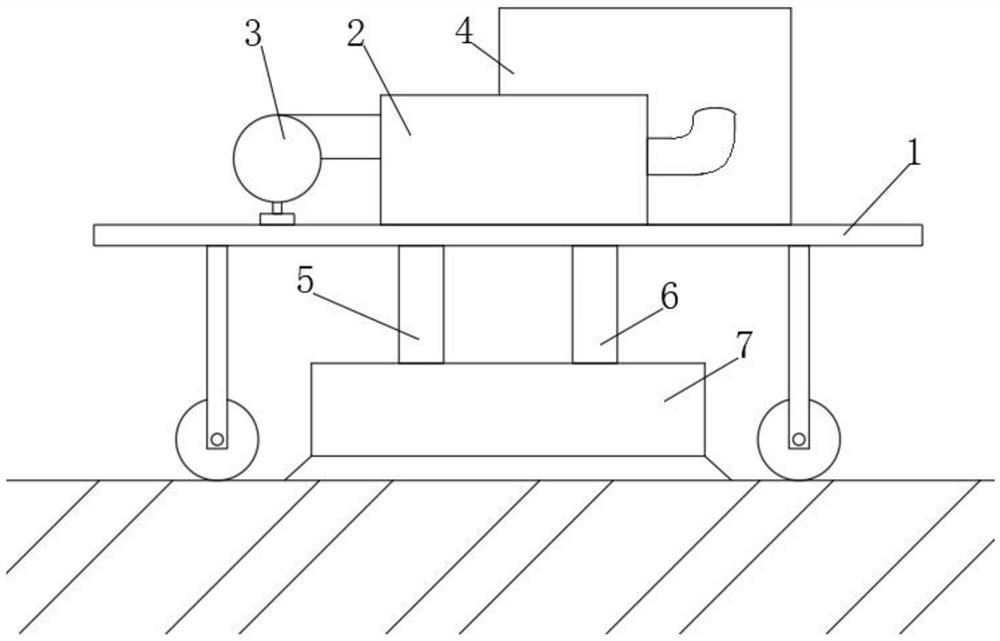

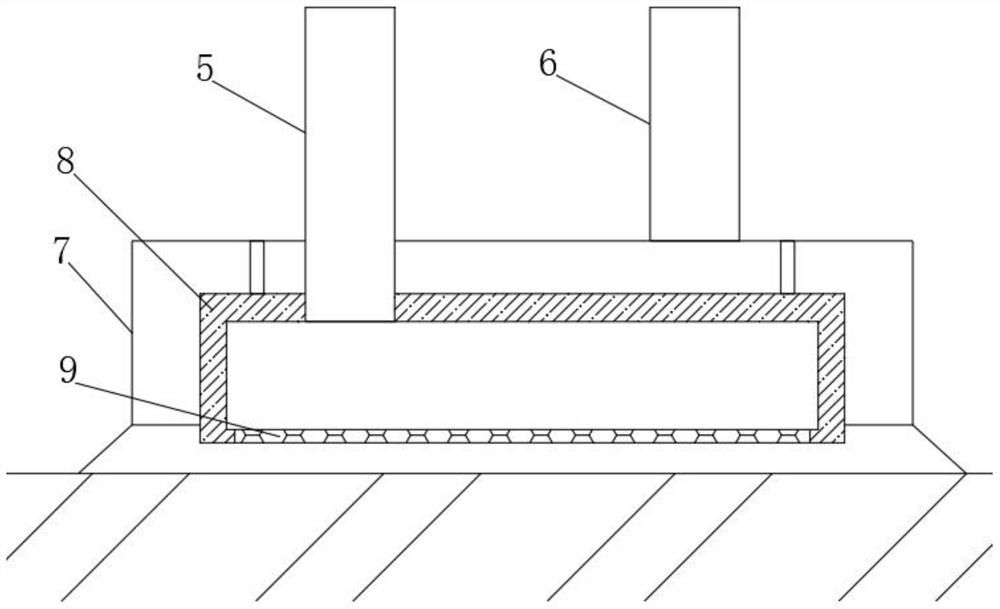

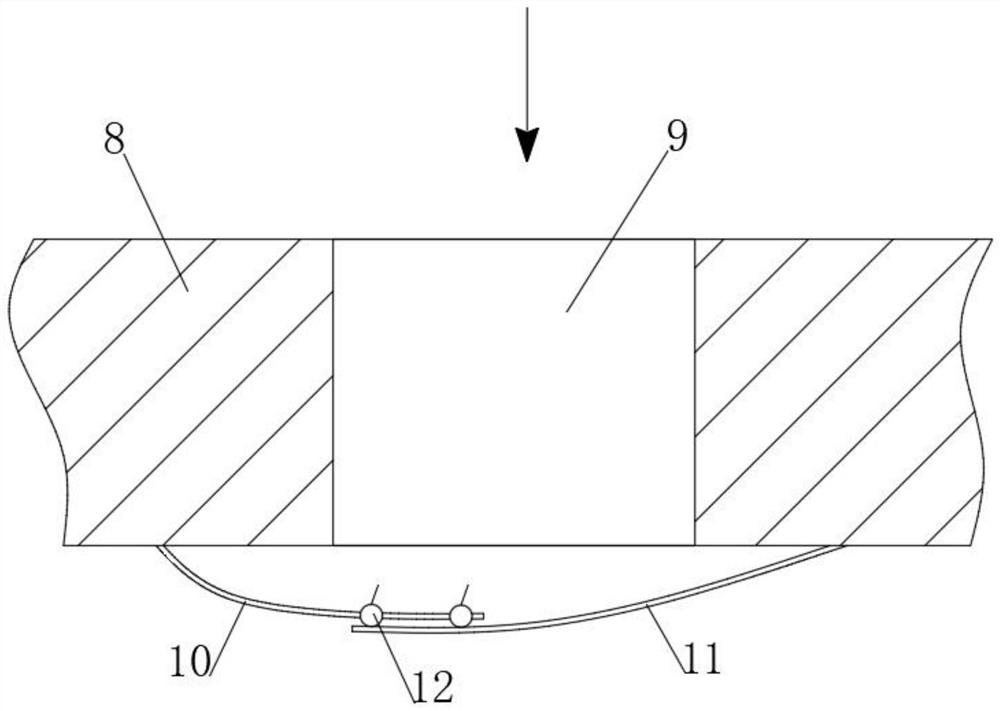

[0041] see Figure 1-2 , based on the old asphalt pavement thermal regeneration new type hot air heating equipment, including the chassis car 1, the upper end of the chassis car 1 is fixedly installed with a hot air circulation cylinder 2, a blower 3 and a hot blast stove 4, the hot air circulation cylinder 2 and the hot blast stove 4 are connected to each other, and the blower 3 It communicates with the hot air circulation cylinder 2. The lower end of the chassis car 1 is fixedly connected with an air inlet pipe 5 and a return air pipe 6. The air inlet pipe 5 and the return air pipe 6 are fixed and run through the chassis car 1, and the two are respectively connected to the hot blast stove 4 and the air return pipe 6. The hot air circulation cylinder 2 communicates with each other. The lower ends of the air inlet pipe 5 and the air return pipe 6 are fixedly connected with a hot air cover 7. The inner end of the hot air cover 7 is fixedly connected with a hot air dispersing pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com