Mechanism for controlling valve opening and closing, variable valve device and method

A valve and switch technology, which is applied in the field of vehicles, can solve the problems that the engine performance cannot be guaranteed, and the variable valve structure cannot be installed, so as to achieve the effect of guaranteeing the braking effect in the cylinder, reducing the pressure and reducing the emission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

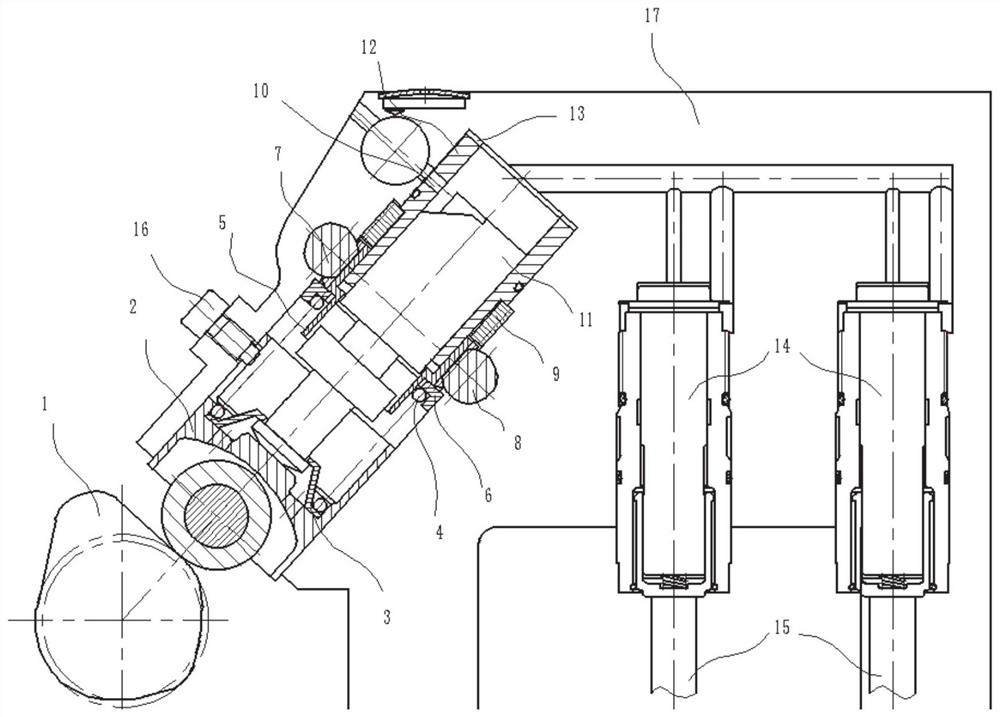

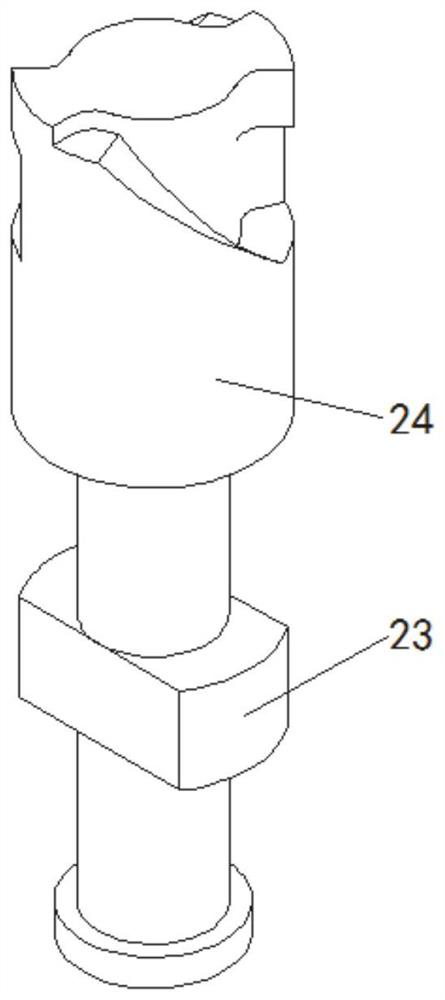

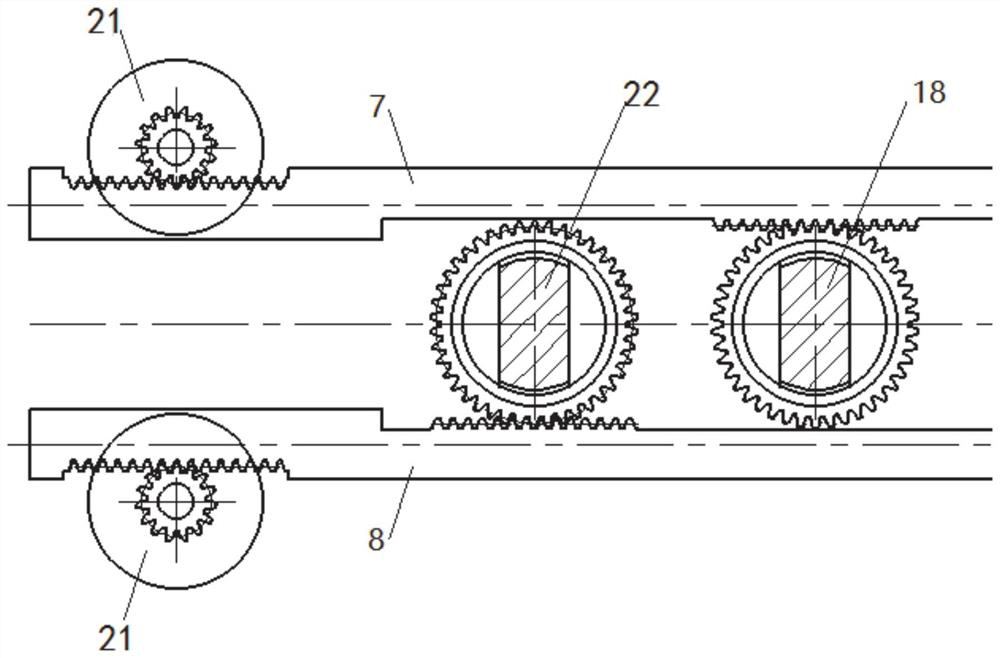

[0044] In a typical embodiment of the present invention, refer to figure 1 and Figure 8 As shown, the mechanism for controlling the valve switch includes a plunger sleeve 12, a plunger is arranged in the plunger sleeve, one end of the plunger is set beyond the bottom end of the plunger, and a rotatable control sleeve 5 is arranged at the bottom end of the plunger. The plunger is provided with an oil control profile, and the inner side of the control sleeve is provided with a control groove for the plunger to slide up and down, and the control groove of the control sleeve is engaged with the peripheral side of the plunger, and the control sleeve can drive the plunger to rotate together through the control groove.

[0045] One end of the plunger is set beyond the control sleeve, and the plunger sleeve is provided with an oil inlet and outlet hole and an oil outlet hole on the side near the other end of the plunger. An oil chamber is formed between the plug sleeves, and the end...

Embodiment 2

[0062] This embodiment discloses a variable valve device, including a camshaft, an intake valve and / or an exhaust valve, and the intake valve and / or exhaust valve are connected to the mechanism for controlling the valve switch described in Embodiment 1 , the camshaft is provided with at least one cam, the cam can be in contact with the rolling body, and the camshaft drives the corresponding cam to rotate, thereby pushing the plunger to move relative to the plunger sleeve through the rolling body, thereby controlling the mechanism for controlling the valve switch and the intake air valve and / or exhaust valve communication.

[0063] Further, the cam not only sets the first projection 19, refer to Figure 7 As shown, the exhaust cam is also provided with a second protrusion 20, the protrusion amplitude of the second protrusion is the same as or different from that of the first protrusion, and there is a gap between the second protrusion and the first protrusion. The set distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com