Hydrogen chloride self-pressurizing conveying and drying device

A drying device and hydrogen chloride technology, applied in the direction of chlorine/hydrogen chloride, chlorine/hydrogen chloride purification, inorganic chemistry, etc., can solve the problems of affecting absorption effect, concentration reduction, high energy consumption, etc., and achieve good drying effect and guaranteed concentration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

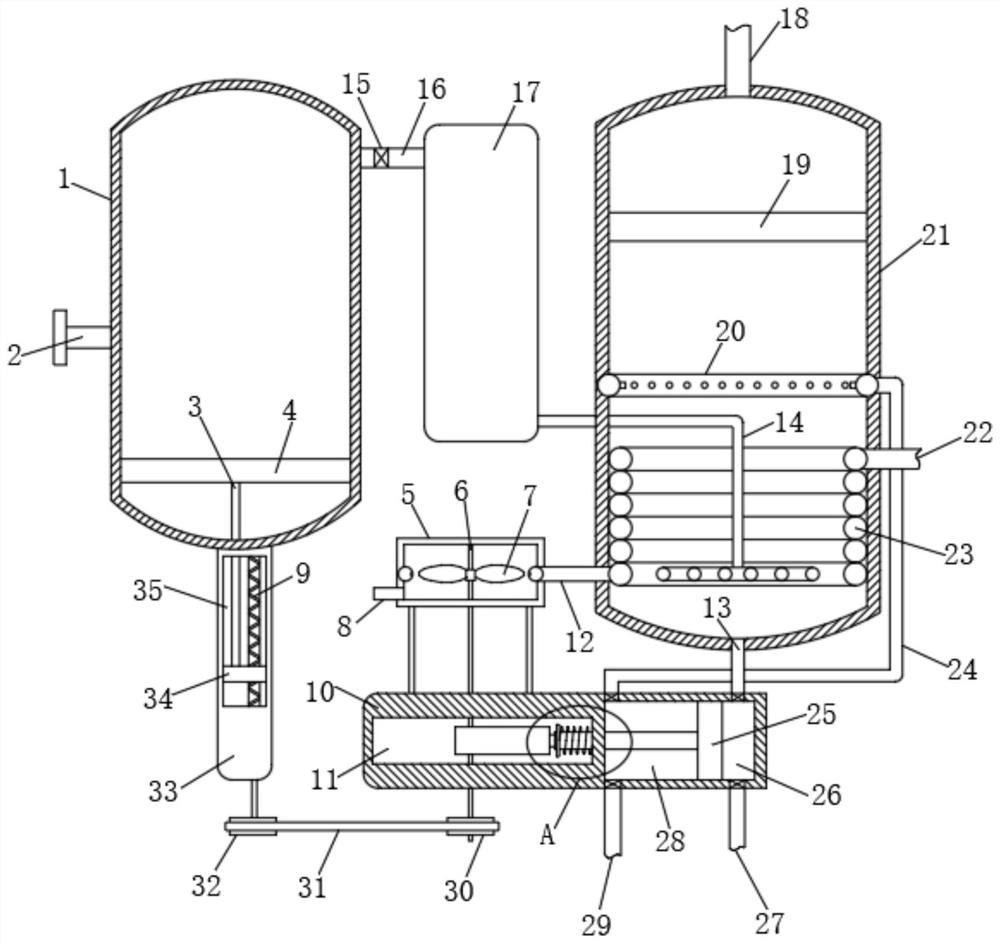

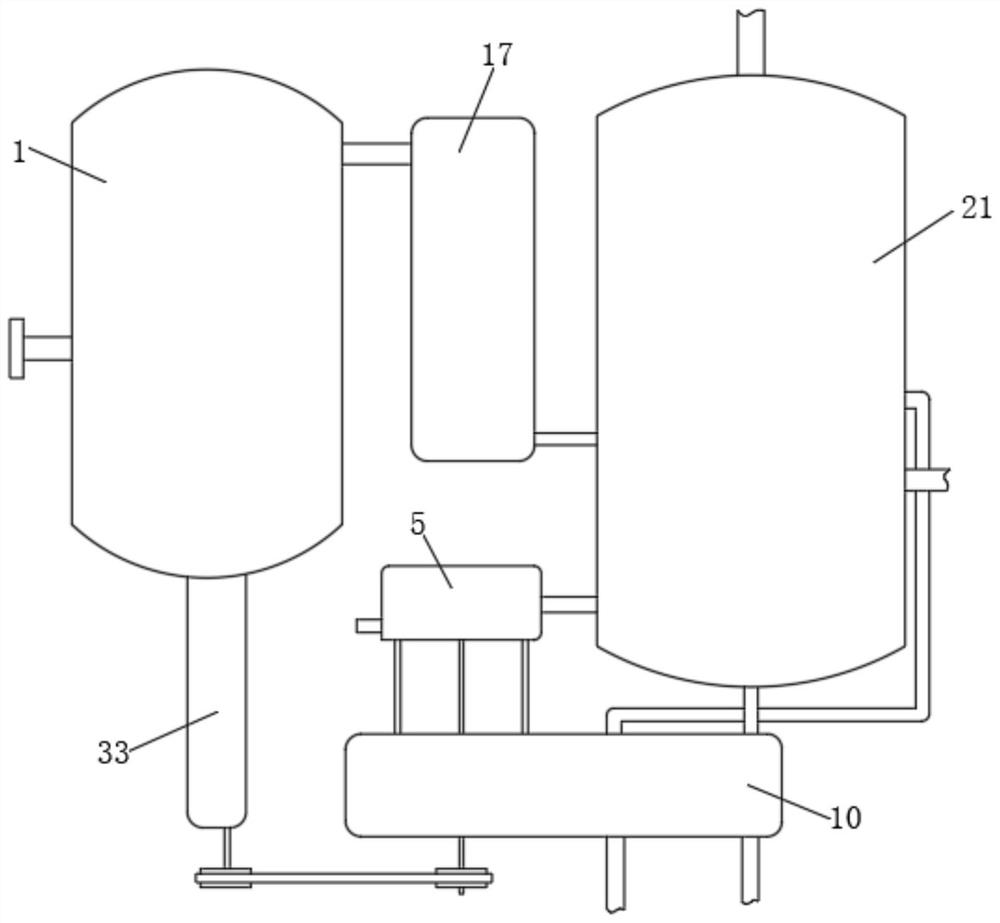

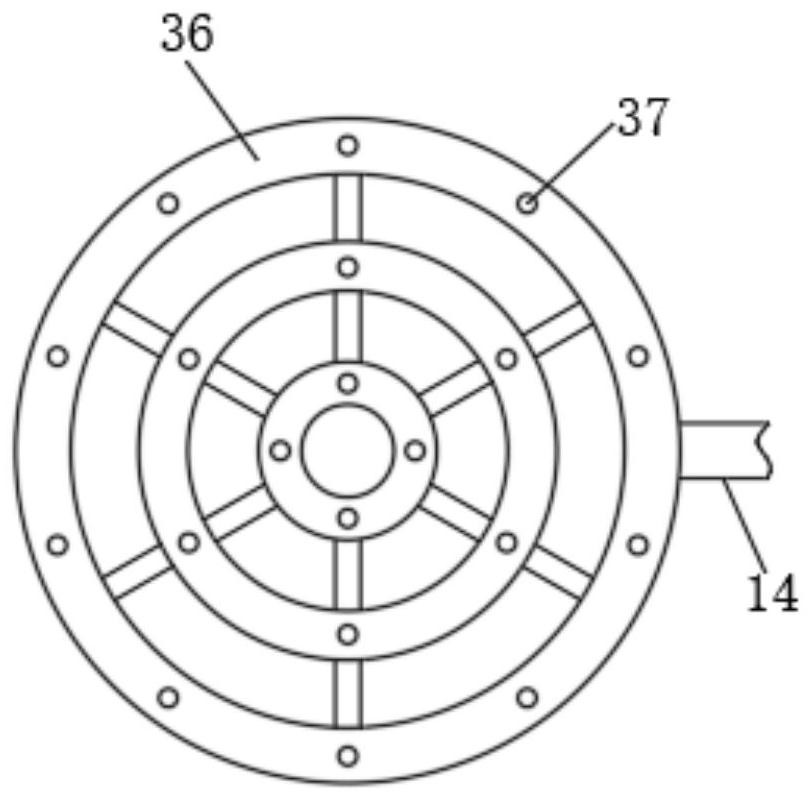

[0040] A hydrogen chloride self-pressure conveying and drying device, such as Figure 1~5 As shown, the device includes a self-pressure delivery tank 1, a graphite cooler 17, a drying tank 21, a device column 33, a booster mechanism, an air outlet mechanism, a heat exchange mechanism, a glass mesh eliminator 19, a cylindrical housing 5, Driving mechanism, body 10, reciprocating mechanism, piston 25, pumping mechanism, pumping mechanism and transmission mechanism.

[0041] One side wall of the self-pressure conveying tank 1 is provided with an air inlet pipe 2, and the other side side wall is provided with an air outlet pipe 16, and a pressure valve 15 is installed in the air outlet pipe 16, and the air outlet pipe 16 is connected with the inlet end of the graphite cooler 17, A device column 33 is fixedly connected to the outside of the bottom of the self-pressure delivery tank 1 , and a bar-shaped cavity 35 is arranged in the device column 33 , and a pressurization mechanism i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com