Method for measuring average Mach number of nozzle outlet

A technology of nozzle outlet and measurement method, which is applied in the direction of temperature measurement of moving fluid, measurement device, measurement of fluid pressure, etc., can solve the problems of distortion of measurement results, interference of nozzle flow field, and rarely used nozzle outlet flow rate, etc., so as to reduce disturbance , the effect of measuring low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] This embodiment is a method for measuring the average Mach number of a nozzle outlet, comprising the following steps:

[0051] Step 1: Determine the throat area A 1 :

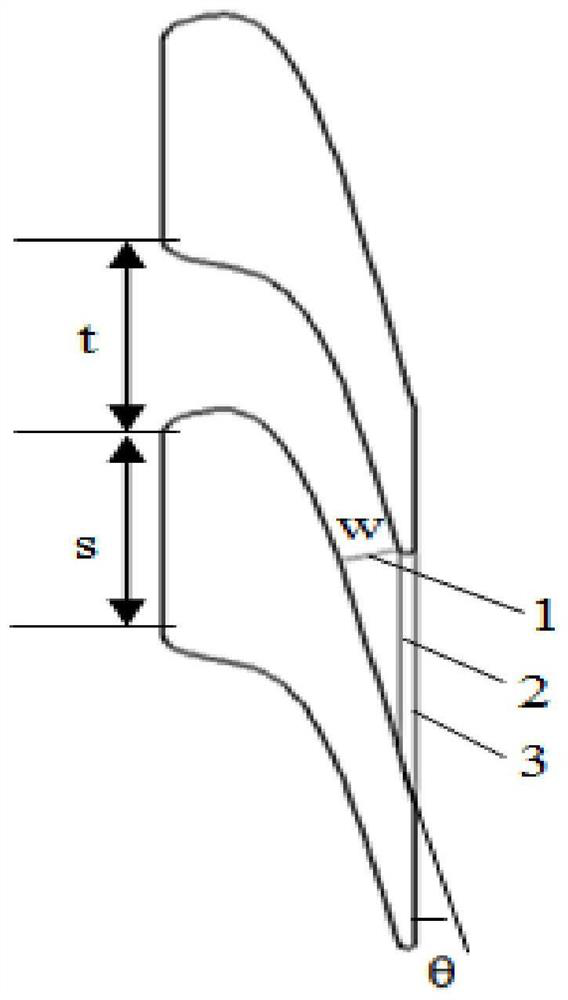

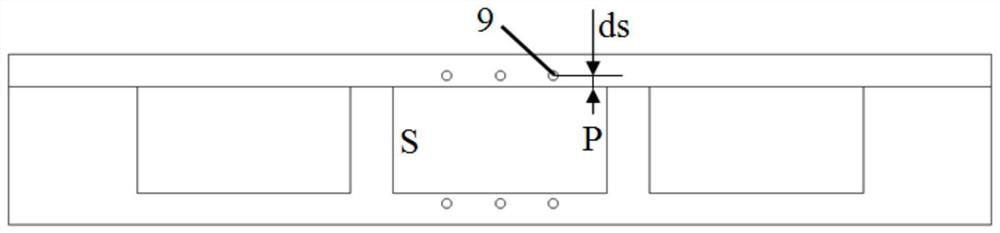

[0052] By measuring the width w of the nozzle throat section 1 and the nozzle height h, the throat area A of the nozzle is obtained 1 , namely A 1 =w×h;

[0053] Step 2: Total temperature T of nozzle inlet airflow 0 * Measurement:

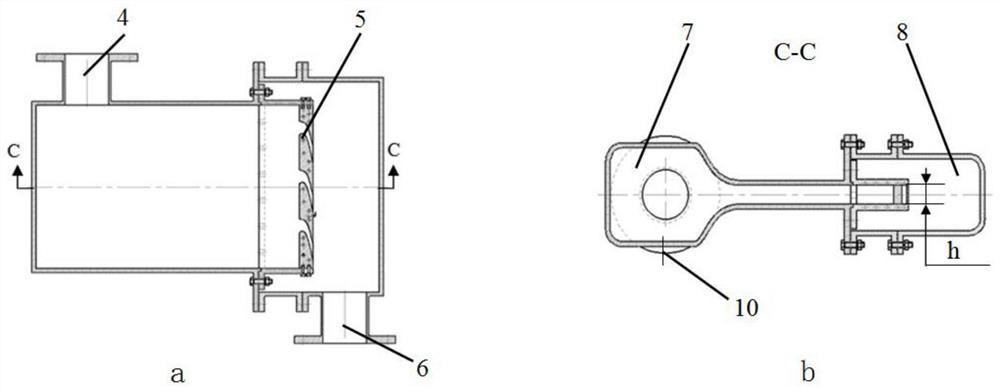

[0054] A total temperature measuring point 10 is set at any position in the middle of the inner surface of the air intake cavity 7; a hole is processed on the air intake cavity housing, and the hole is made to correspond to the total temperature measuring point. Put the total temperature probe into the air inlet cavity through the hole, and make the vertical distance between the end of the total temperature probe and the total temperature measuring point be 5mm. Measure the total temperature T of the nozzle inlet airflow through the total temperature probe 0 * . Mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com