Correction method of optical proximity correction model

A technology of optical proximity correction and model, which is applied in the direction of optics, originals for photomechanical processing, and photoplate making process of pattern surface, etc. It can solve the problems of distortion, deformation and deviation, and the size reduction of semiconductor devices, and achieve the improvement of precision , reduce the error, improve the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] It is known from the background art that optical proximity correction is used to form expected target patterns on a wafer. However, the accuracy of optical proximity correction still needs to be improved.

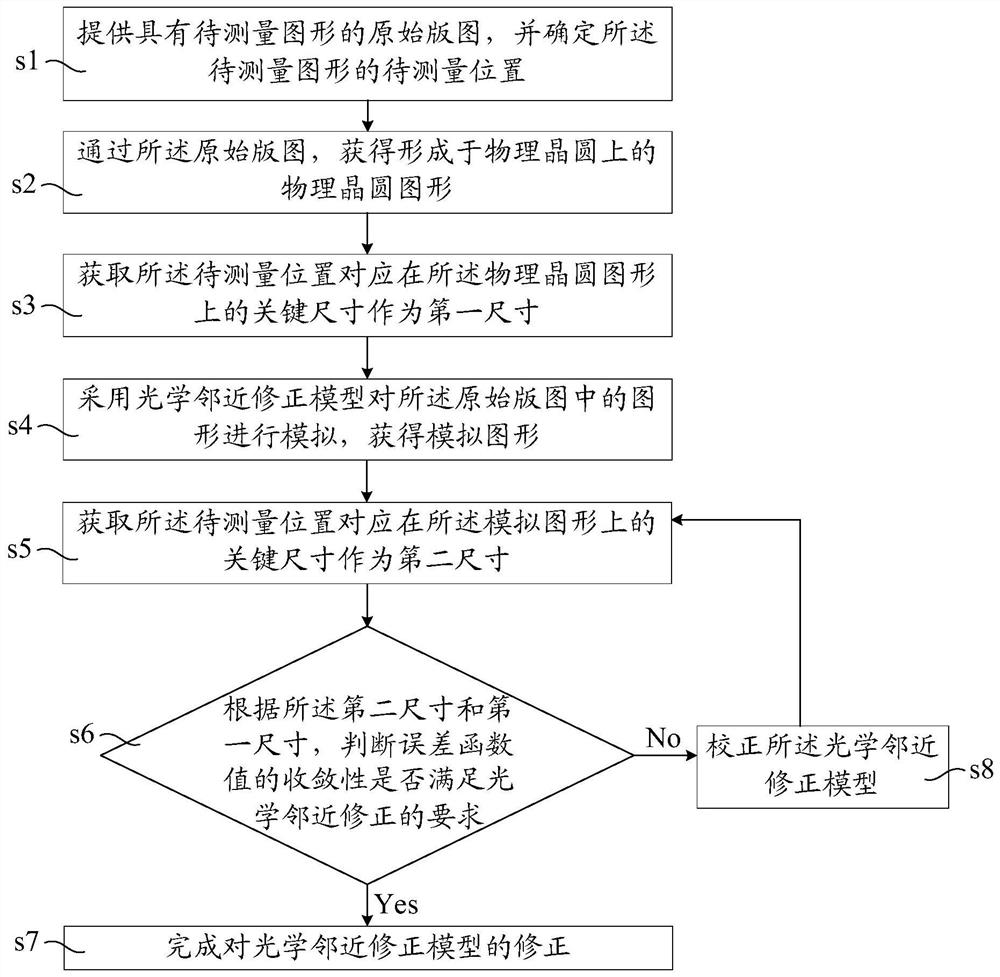

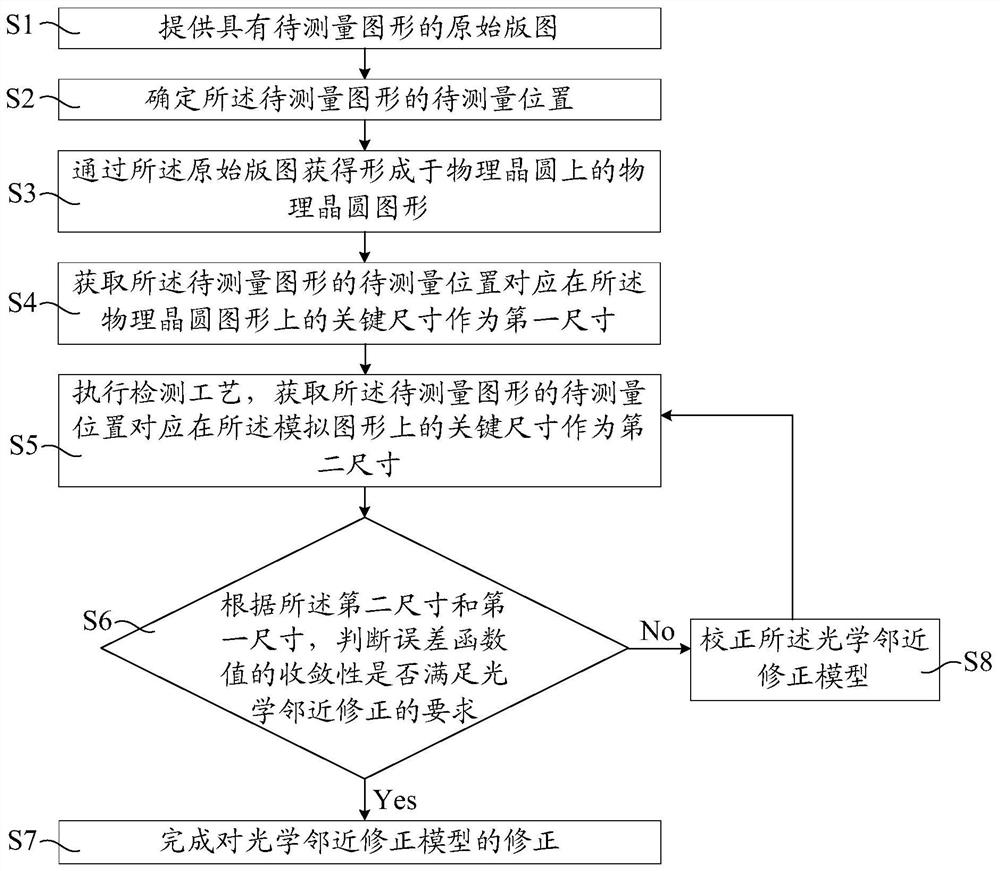

[0036] refer to figure 1 , shows a schematic flowchart of an optical proximity correction model calibration method.

[0037] The steps of the optical proximity correction model calibration method include:

[0038] Execute step s1, provide the original layout (layout) with the pattern to be measured, and determine the position to be measured of the pattern to be measured;

[0039] Execute step s2, obtain the physical wafer pattern formed on the physical wafer through the original layout;

[0040] Executing step s3, acquiring the critical dimension (CD) corresponding to the location to be measured on the physical wafer pattern as a first dimension;

[0041]Execute step s4, using the optical proximity correction model to simulate the graphics in the original layout ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap