Thin-wall plastic part injection molding process parameter multi-objective optimization method

A technology of multi-objective optimization and process parameters, which is applied in the field of process parameter optimization and multi-objective optimization of thin-walled plastic injection molding process parameters. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

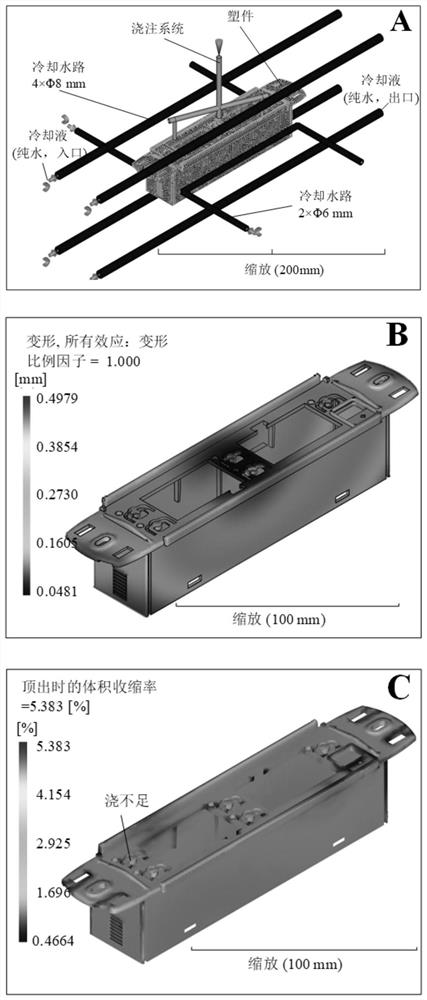

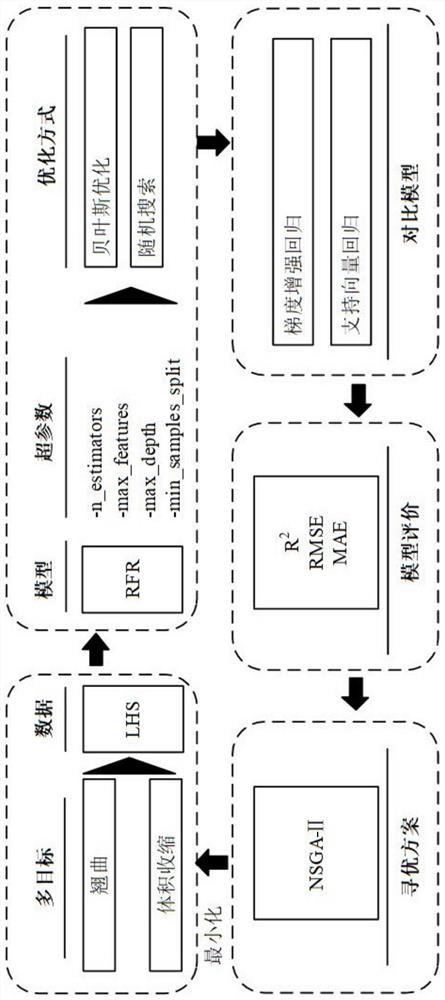

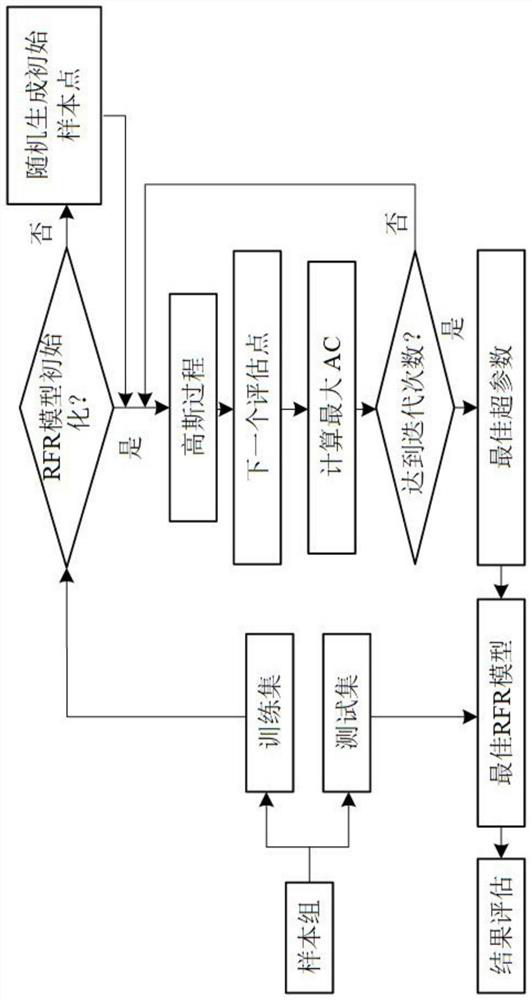

[0027] This multi-objective optimization method for injection molding process parameters of thin-walled plastic parts takes minimizing warpage and volume shrinkage as the two optimization objectives, and combines Moldflow simulation software with Latin hypercube sampling (LHS) to study different process parameters The influence of defects on plastic parts, and using Bayesian optimization improved random forest regression (BO-RFR) and non-dominated sorting genetic algorithm (Non-dominated sorting genetic algorithm II, NSGA-II) for multi-objective optimization. First, on the basis of LHS, random forest regression (RFR) is used to construct the mathematical relationship between the injection molding process parameters and the two optimization objectives; (Probability of improvement, PI) as the acquisition function, establish a Bayesian optimization algorithm (Bayesian optimization, BO), and use this to optimize the hyperparameters of RFR, so as to construct the BO-RFR model; final...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com