Fly ash winnowing floating bead equipment and winnowing separation method thereof

A technology for separation of fly ash and gas ash, which is applied in separation methods, solid separation, and dispersed particle separation, etc. It can solve the problems of high maintenance cost and production cost, reduced recovery efficiency of floating beads, and large power source output, etc., and achieves reduction Difficulty in washing, cost reduction, and effect of prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

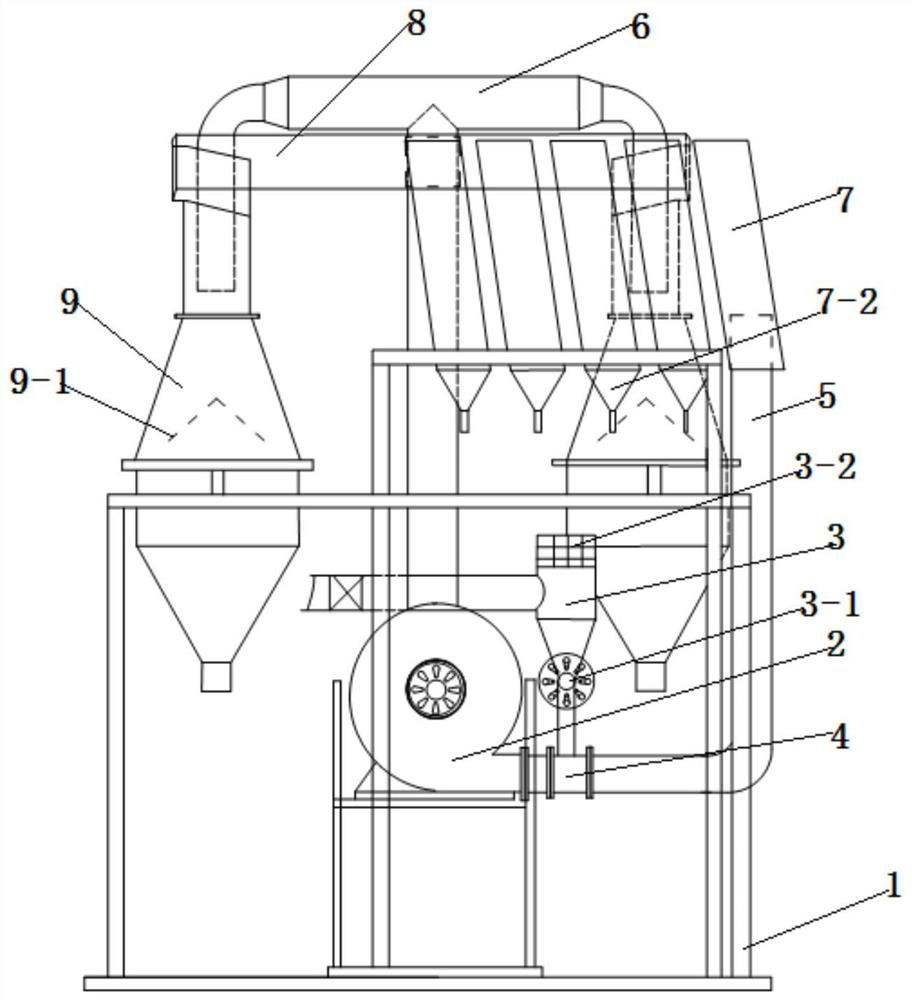

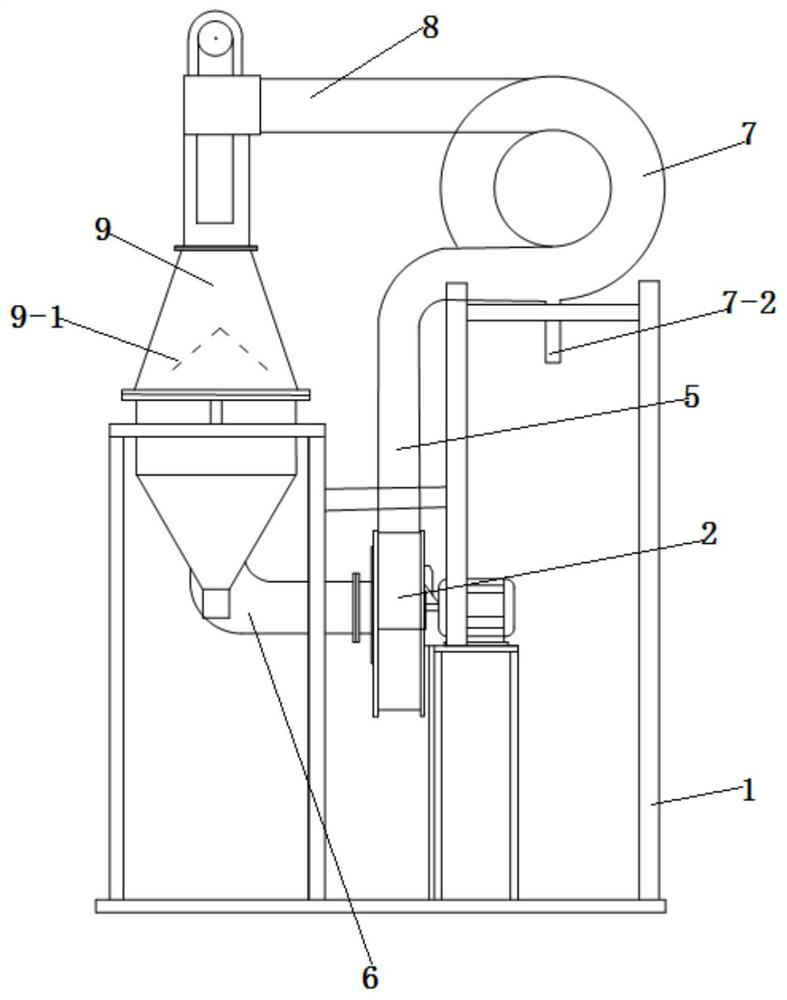

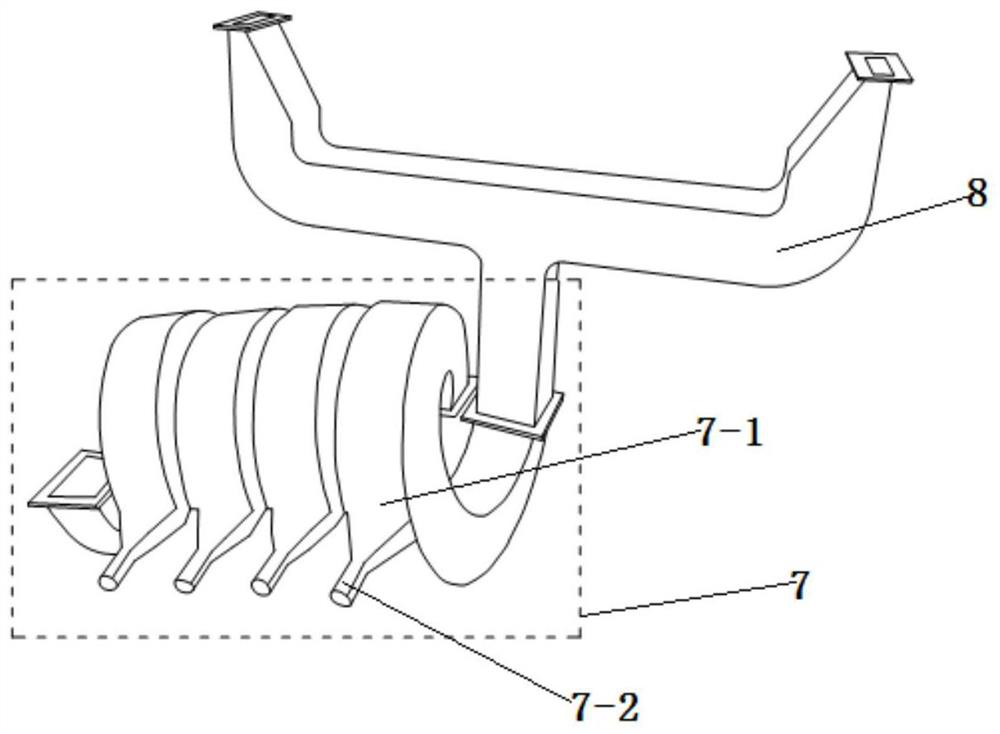

[0038] combine figure 1 , figure 2 and image 3 As shown, a kind of fly ash air separation bleaching device in the present embodiment 1 comprises support 1, fly ash conveying mechanism, fly ash winnowing mechanism and fly ash recovery mechanism, fly ash conveying mechanism, powder Coal ash winnowing mechanism and fly ash recovery mechanism are all inlaid and installed on the support 1 for fixing, and the described fly ash conveying mechanism includes circulating fan 2, ash collecting hopper 3, mixer 4, air supply pipe 5 and suction Pipe 6, the circulating fan 2 transports the fly ash to the fly ash winnowing mechanism; the ash discharge valve 3-1 is arranged under the ash collecting hopper 3 to prevent the pressure gas from leaking out, and the dust collector 3 is arranged above the ash collecting hopper 3 -2, to prevent the secondary pollution of fly ash and protect the environment. In this embodiment, the dust collector 3-2 is a bag filter, and the bottom of the dust coll...

Embodiment 2

[0046] A kind of fly ash winnowing bleaching equipment in the comparative patent is used to wind fly ash and drift beads, and the test is carried out in the workshop, and 1473.5g of power plant raw ash with the same composition and quality is selected, and after the fly ash wind The weight of the enriched ash at the winnowing place of the selection mechanism is 421g, and the small ash recovered at the fly ash recovery system is 1052.5g. Collected ash accounted for 28.5% of the original ash ratio of the power plant, and floating beads accounted for 1.66% of the original ash ratio of the power plant.

[0047] The above test shows that, using a kind of fly ash winnowing and floating pearl equipment in this embodiment to carry out floating pearl winnowing, the content of enriched ash accounts for 28.5% of the original ash ratio of the power plant, and the content of floating pearls in the enriched ash is 28.5%. Accounting for 70% of the content of floating beads in the raw ash of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com