Multifunctional ceramic tea set manufacturing equipment

A multi-functional, ceramic technology, used in ceramic molding machines, auxiliary molding equipment, manufacturing tools, etc., can solve problems such as excess power, and achieve the effect of avoiding waste, ensuring safety, and high fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

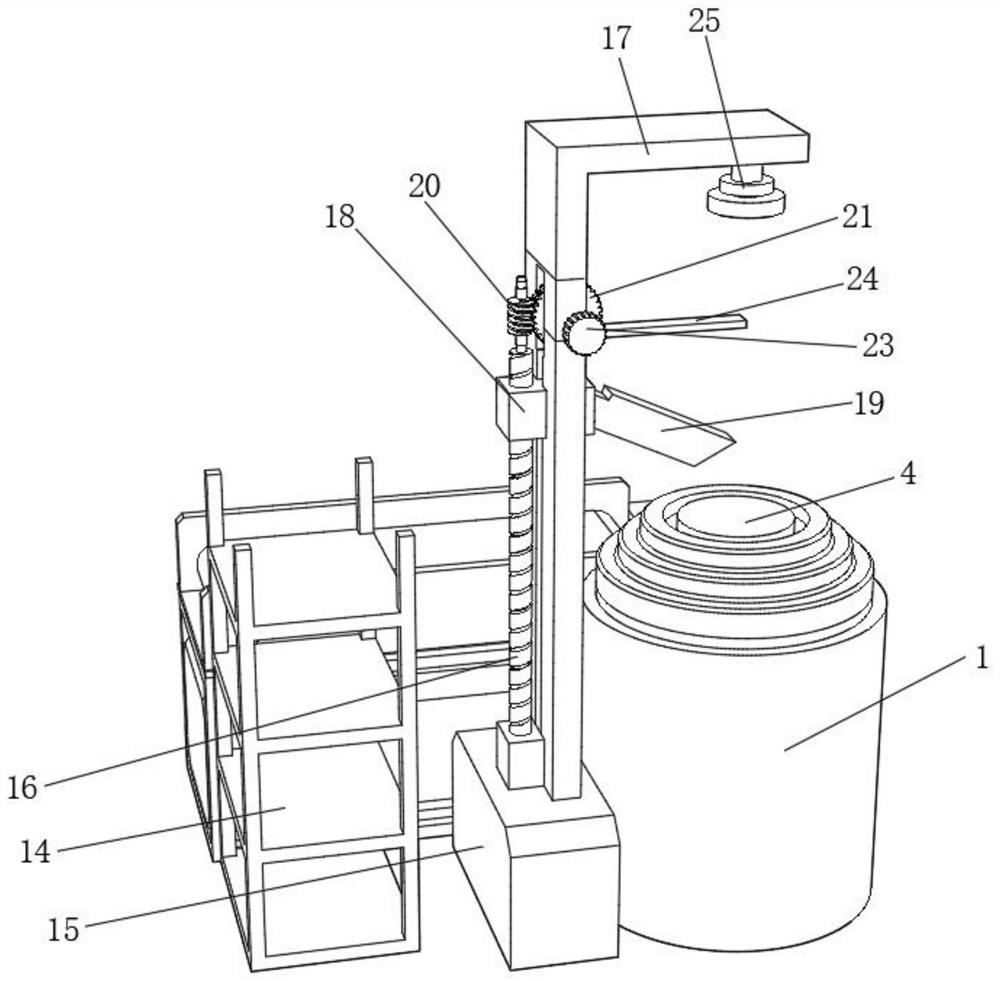

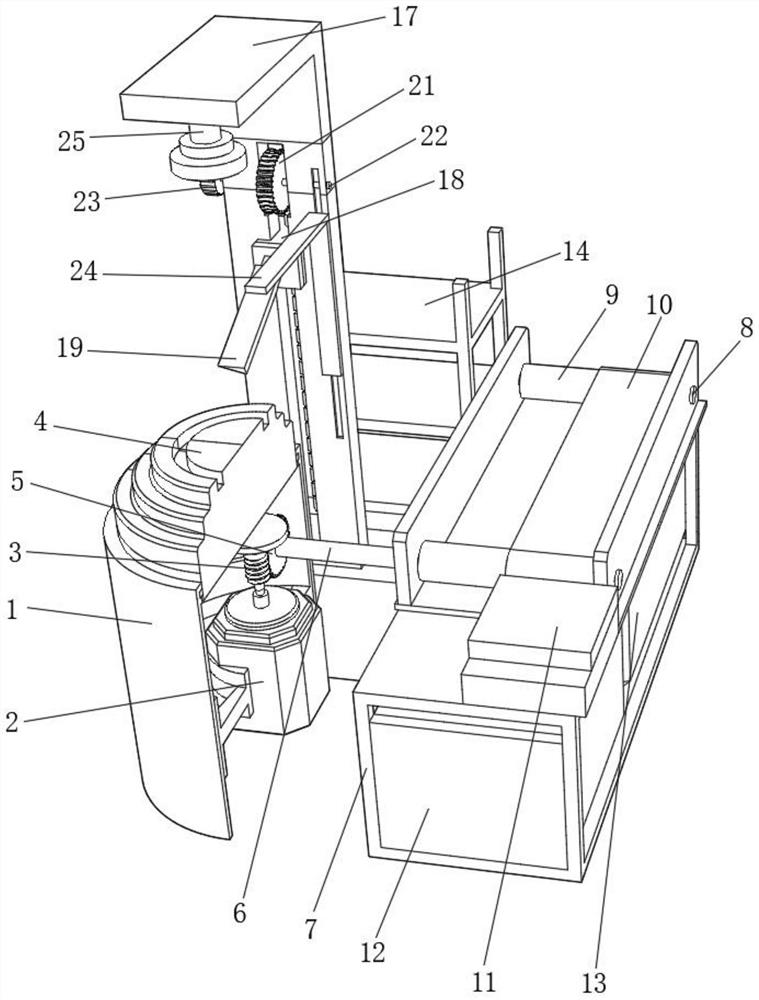

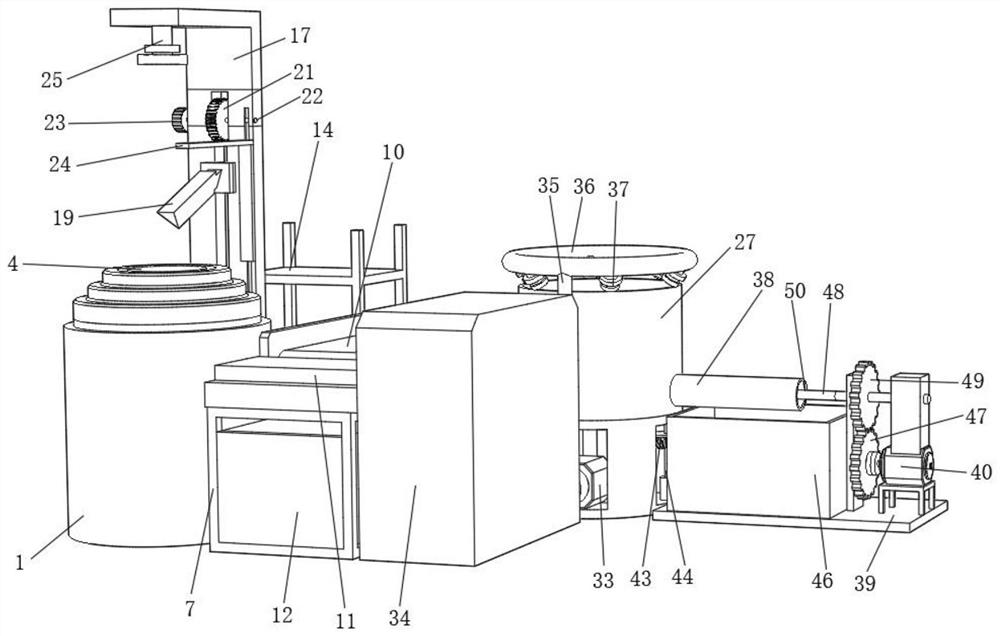

[0032] refer to Figure 1-2 , a multifunctional ceramic tea set production equipment, comprising a fixed shell 1, a rotary table 4 is slidably connected to one side of the inner circumference of the fixed shell 1, a first motor 2 is fixed on the bottom of the inner wall of the fixed shell 1 by bolts, and the output shaft of the first motor 2 One end of the key is connected with the first worm 3, and one end of the first worm 3 is fixedly connected with the turntable 4, and one side of the fixed shell 1 is provided with a fixed block 15, and the upper surface of the fixed block 15 is movably connected with a screw rod 16, through which the fixed block The setting of screw mandrel 16 on 15 can adjust trimming knife 19 up and down, and fixation is higher, and the trimming effect to green body is better, and the line of tea set is smoother, and screw mandrel 16 end keys are connected with second worm screw 20, fixed The upper surface of the block 15 is fixed with a support frame 1...

Embodiment 2

[0036] refer to Figure 3-4 , a multifunctional ceramic tea set production equipment, comprising a mounting frame 26, the mounting frame 26 is arranged on one side of the fixed frame 7, the upper surface of the mounting frame 26 is provided with a cleaning bucket 27, and the outer wall of the cleaning bucket 27 is provided with a sewage outlet, There is a sewage outlet pipe 38 fixed by bolts in the sewage outlet. Through the installation of the sewage pipe 38 on the cleaning bucket 27, the mud after cleaning the green body can be discharged faster, preventing the sludge water from polluting the green body, and ensuring the quality of tea set making , the bottom of the inner wall of the cleaning bucket 27 is fixed with a placement platform 28 by bolts, and one side of the circumference of the placement platform 28 is respectively sleeved with a hollow plate 29 and a filter plate 30. It can facilitate the cleaning of the green body. Multiple green bodies can be placed on the hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com