Preparation method of tensile flame-retardant fabric

A technology of flame-retardant fabrics and tensile strength, which is applied in the field of fiber fabric production, can solve the problems of insufficient softness and poor wearing comfort, and achieve the effects of improving flame-retardant effects, increasing service life, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

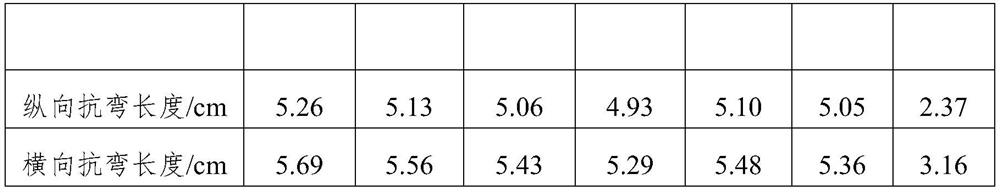

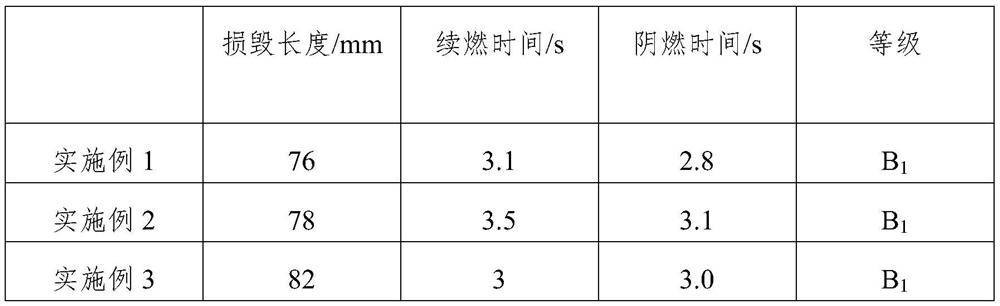

Embodiment 1

[0019] The preparation method of the tensile and flame-retardant fabric of the present embodiment 1, the preparation method comprises:

[0020] Prepare the flame-retardant layer: the warp of the flame-retardant layer is polyimide fiber, and the weft is polytetrafluoroethylene fiber. The warp and weft of the flame-retardant layer are all immersed in a mass percentage of 0.5% dispersant and 2% flame retardant and 97.5% distilled water to form a flame-retardant finishing solution to obtain warp flame-retardant fibers and weft flame-retardant fibers, and weave the warp flame-retardant fibers and weft flame-retardant fibers into a flame-retardant layer, wherein the flame retardant is a mass ratio of 1:2: 0.5 of tributyl phosphate, tricresyl phosphate and decabromodiphenyl ether;

[0021] Prepare the heat insulation layer: weave the warp and weft threads into flame-retardant aramid / cotton blended fabrics to form a flame-retardant layer;

[0022] Preparation of tensile and flame-ret...

Embodiment 2

[0024] The preparation method of the tensile flame-retardant fabric of the present embodiment 2, the preparation method comprises:

[0025] Prepare the flame-retardant layer: the warp of the flame-retardant layer is polyimide fiber, and the weft is polytetrafluoroethylene fiber. The warp and weft of the flame-retardant layer are all immersed in a mass percentage of 0.1% dispersant and 5% flame retardant and 94.9% distilled water to form a flame-retardant finishing solution to obtain warp flame-retardant fibers and weft flame-retardant fibers, and weave the warp flame-retardant fibers and weft flame-retardant fibers into a flame-retardant layer, wherein the flame retardant is a mass ratio of 1:1: 1 composed of tributyl phosphate, tricresyl phosphate and decabromodiphenyl ether;

[0026] Prepare the heat insulation layer: Weave the flame-retardant polyester / cotton blended fabric with warp and weft into a flame-retardant layer:

[0027] Preparation of tensile and flame-retardant...

Embodiment 3

[0029] The preparation method of the tensile and flame-retardant fabric of the present embodiment 3, the preparation method comprises:

[0030] Prepare the flame-retardant layer: the warp of the flame-retardant layer is polyimide fiber, and the weft is polytetrafluoroethylene fiber. The warp and weft of the flame-retardant layer are all immersed in a mass percentage of 1% dispersant and 1% flame retardant and 98% distilled water to form a flame-retardant finishing solution to obtain warp flame-retardant fibers and weft flame-retardant fibers, and weave the warp flame-retardant fibers and weft flame-retardant fibers into a flame-retardant layer, wherein the flame retardant is a mass ratio of 1:3: 0.1 of tributyl phosphate, tricresyl phosphate and decabromodiphenyl ether;

[0031] Prepare the heat insulation layer: weave the warp and weft threads into flame-retardant aramid / cotton blended fabrics to form a flame-retardant layer;

[0032] Preparation of tensile and flame-retarda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com