Production method of flaky crystal ferric chloride

A technology of flaky crystallization and production methods, which is applied in the direction of iron halide, can solve the problems of difficult production control, large production sites and labor intensity, and low material utilization rate, so as to reduce the difficulty of production control and avoid high-intensity labor , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

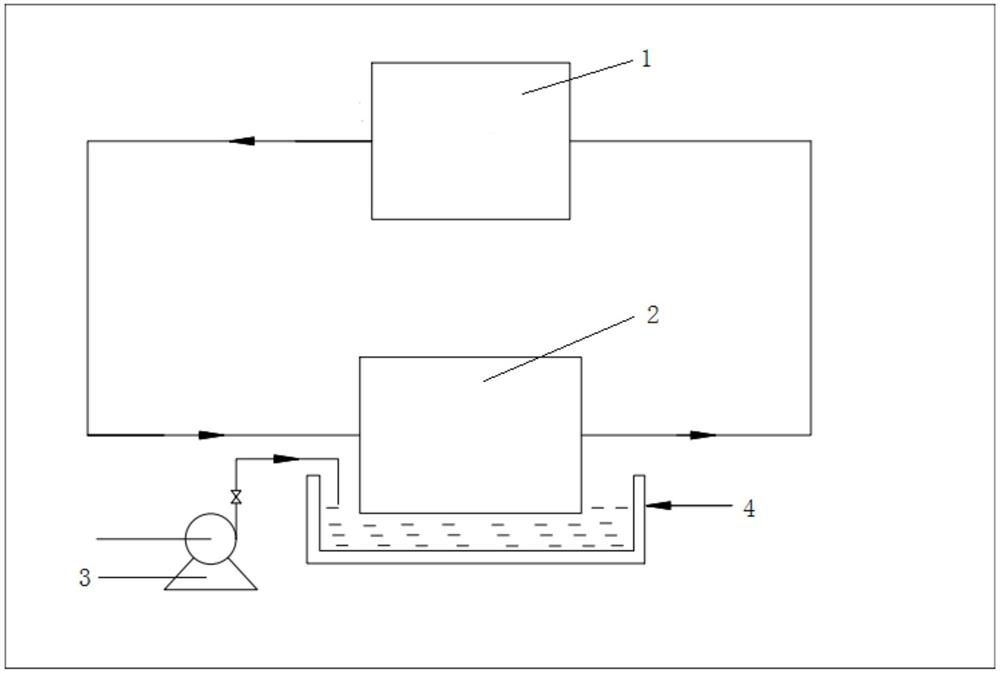

Method used

Image

Examples

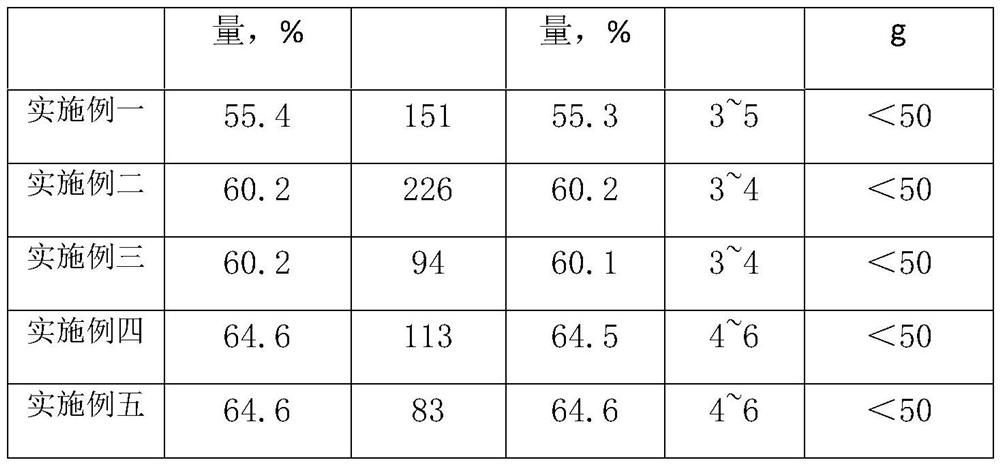

Embodiment 1

[0031] (1) Use a chiller to cool the circulating water to 5°C as a circulating refrigerant and inject it into the drum jacket;

[0032] (2) Concentration is that the ferric chloride concentrated solution of 55.4% is squeezed in the flaking machine feed tank of cylinder diameter 600mm, long 800mm, and the liquid level of ferric chloride concentrated solution in the feed tank is slightly higher than the lowest end of the cylinder, control The amount of material, so that the material is always not lower than the lowest end of the outer wall of the drum during the production process;

[0033] (3) Turn on the flaker switch, and control the rotation speed of the drum at 40r / hr;

[0034] (4) the concentrated solution of ferric chloride adhered to the outer wall of the drum leaves the trough with the rotation of the drum, and gradually cools on the outer wall of the drum at low temperature and converts into solid crystalline ferric chloride;

[0035] (5) The crystallized material on ...

Embodiment 2

[0037] (1) Use a chiller to cool the circulating water to 5°C as a circulating refrigerant and inject it into the drum jacket;

[0038] (2) Concentration is that the ferric chloride concentrated solution of 60.2% is squeezed in the flaking machine hopper of cylinder diameter 600mm, long 800mm, and the liquid level of ferric chloride concentrated solution in the hopper is slightly higher than the lowest end of the cylinder, control The amount of material, so that the material is always not lower than the lowest end of the outer wall of the drum during the production process;

[0039] (3) Turn on the flaker switch, and control the rotation speed of the drum at 60r / hr;

[0040] (4) the concentrated solution of ferric chloride adhered to the outer wall of the drum leaves the trough with the rotation of the drum, and gradually cools on the outer wall of the drum at low temperature and converts into solid crystalline ferric chloride;

[0041] (5) The crystallized material on the cy...

Embodiment 3

[0043] (1) Use a chiller to cool the circulating water to 20°C as a circulating refrigerant and inject it into the drum jacket;

[0044] (2) Concentration is that the ferric chloride concentrated solution of 60.2% is squeezed in the flaking machine hopper of cylinder diameter 600mm, long 800mm, and the liquid level of ferric chloride concentrated solution in the hopper is slightly higher than the lowest end of the cylinder, control The amount of material, so that the material is always not lower than the lowest end of the outer wall of the drum during the production process;

[0045] (3) Turn on the flaker switch, and control the rotation speed of the drum at 25r / hr;

[0046] (4) the concentrated solution of ferric chloride adhered to the outer wall of the drum leaves the trough with the rotation of the drum, and gradually cools on the outer wall of the drum at low temperature and converts into solid crystalline ferric chloride;

[0047] (5) The crystallized material on the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com