TPO environment-friendly particle for sunlight fabric

A technology of sunshine fabrics and particles, applied in textile, yarn, filament/thread forming and other directions, can solve the problem of poor flame retardant effect of sunshine fabrics, and achieve good application prospects, good compatibility, and the effect of reducing odor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

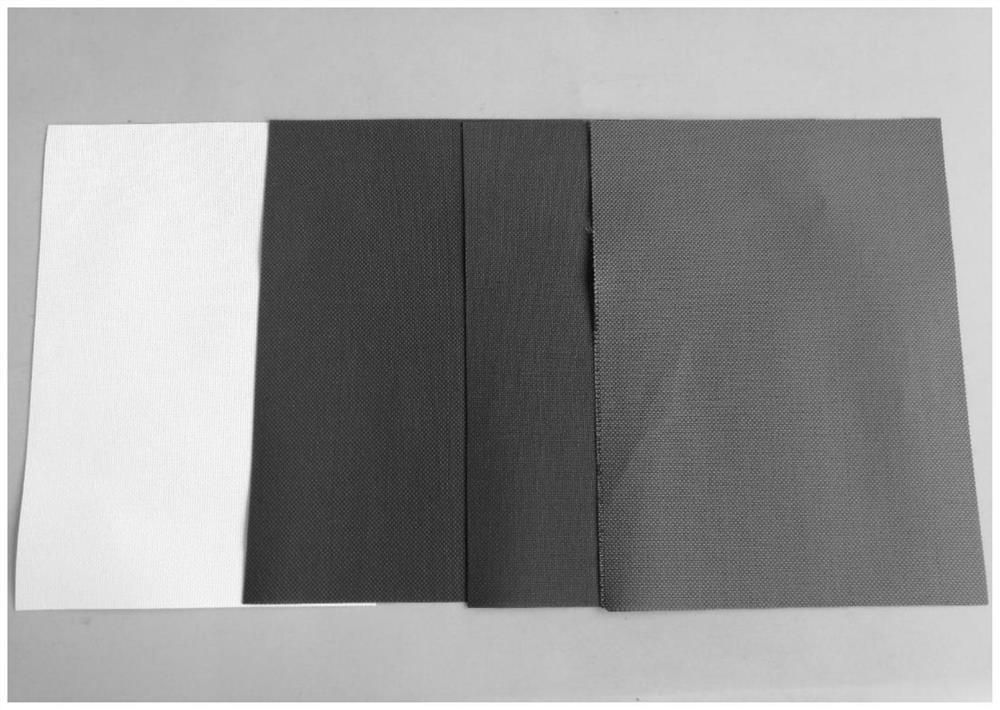

Image

Examples

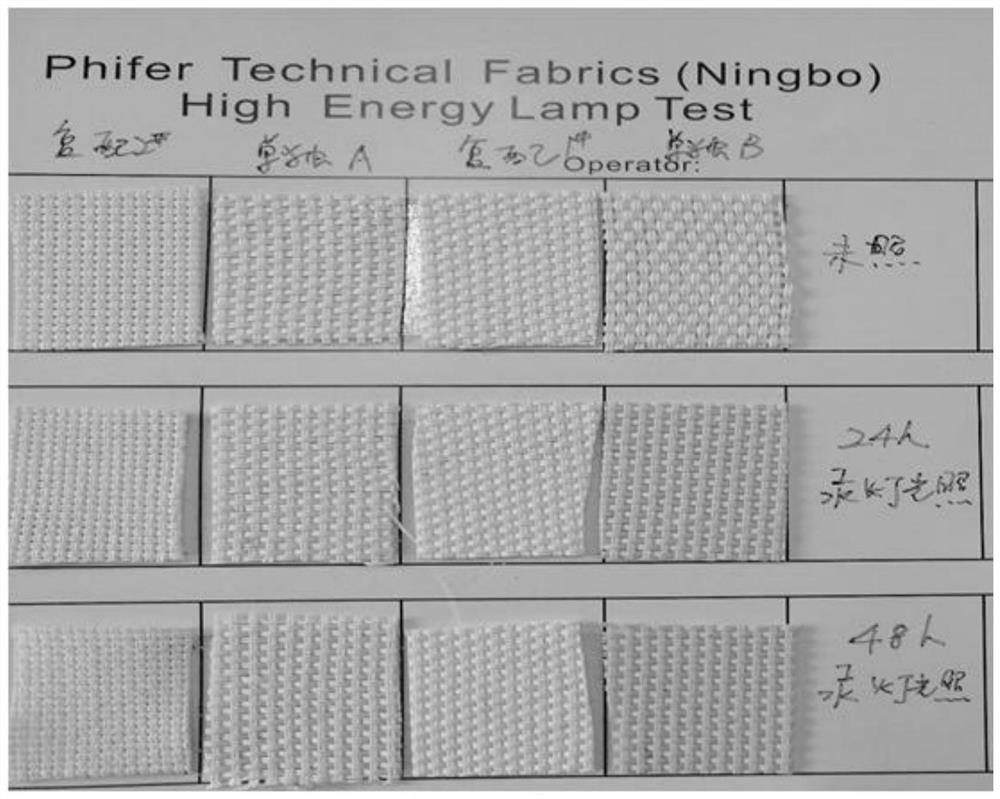

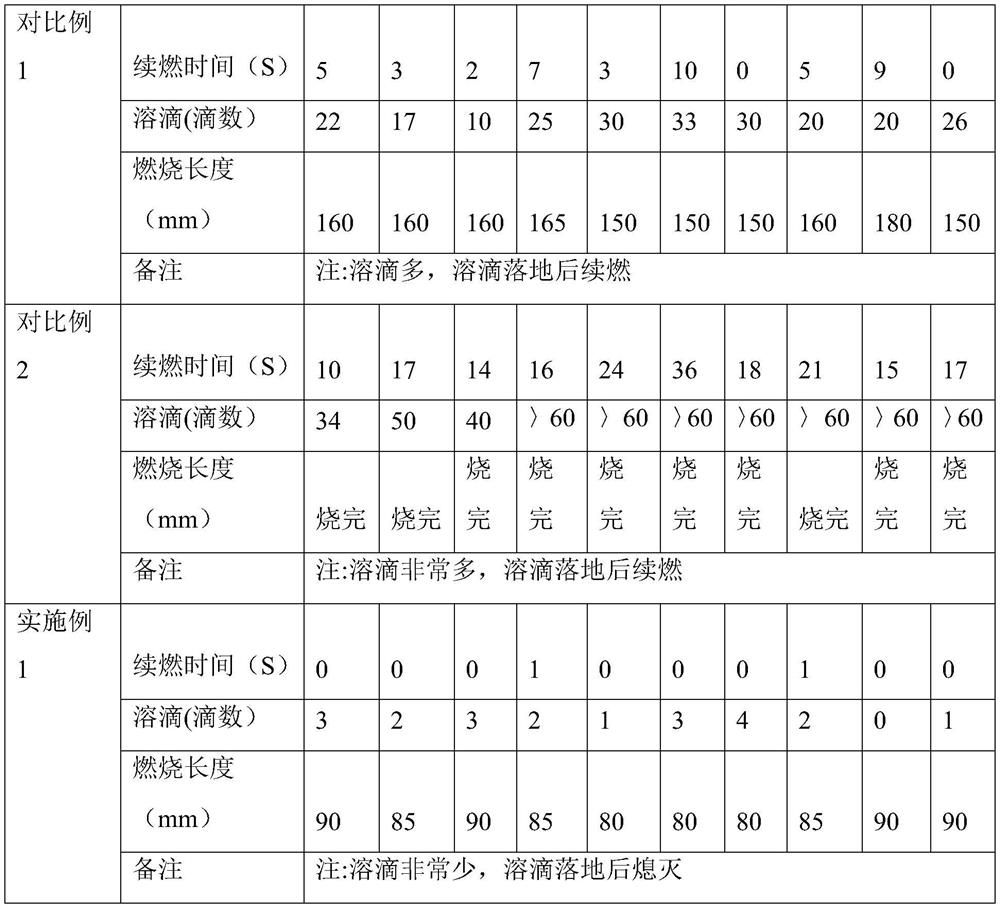

Embodiment 1

[0039]The raw materials of TPO environmental protection particles include: PPR260 (melting value is about 30) 50 parts (weight ratio 45%), ethylene-propylene elastomer 6202 (hardness is about 60A) 40 parts (weight ratio 36%), HS768 ( Talcum powder) 5 parts (weight ratio 4.5%), PP flame-retardant masterbatch FR50C 4 parts (weight ratio 3.4%), PP flame-retardant masterbatch FR50G 4 parts (weight ratio 3.4%), compound antioxidant 0.3 part (weight ratio ratio 0.25%), 0.8 parts of compounded light stabilizer (0.67% by weight), 0.6 parts of ultraviolet absorber UV2344 (0.5% by weight), 0.3 parts of super-dispersed lubricant DP-310 (0.25% by weight), compound 0.2 parts of antibacterial agent (0.17% by weight), 5 parts of rutile titanium dioxide (4.5% by weight), and the rest are pigments. Phosphate ester compound, the compound light stabilizer is a compound of low molecular weight hindered benzoate light stabilizer and high molecular weight hindered amine light stabilizer with a mass...

Embodiment 2

[0070] This embodiment provides TPO environment-friendly particles used indoors (such as for curtains, etc.), and the raw materials include: 50 parts of PPR260 (melting value is about 30), 45 parts of ethylene-propylene elastomer 6202 (hardness is about 60A) in parts by weight , 4 parts of PP flame retardant masterbatch FR50C, 4 parts of PP flame retardant masterbatch FR50G, 0.4 parts of compound antioxidant, 0.8 part of compound light stabilizer, 0.5 part of ultraviolet absorber UV234, 0.2 part of compound antibacterial agent, dispersant 0.3 parts of DP310, 10 parts of talc powder HS-768, 3 parts of rutile DuPont titanium dioxide, pigments are added according to the color requirements, and the mass ratio of the compound antioxidant is 1: 1 Compound, compound light stabilizer is a compound of low molecular weight hindered benzoate light stabilizer (Xinxiu Chemical 5586) and high molecular weight hindered amine light stabilizer (Xinxiu Chemical 901) with a mass ratio of 1:2 , t...

Embodiment 3

[0075] This embodiment provides TPO environment-friendly particles used indoors (such as for curtains, etc.), and the raw materials include: 50 parts of PPR260 (melting value is about 30), 45 parts of ethylene-propylene elastomer 6202 (hardness is about 60A) in parts by weight , 6 parts of PP flame retardant masterbatch FR50C, 6 parts of PP flame retardant masterbatch FR50G, 0.5 part of compound antioxidant, 1 part of compound light stabilizer, 0.7 part of ultraviolet absorber UV234, 0.2 part of compound antibacterial agent, dispersant 0.3 parts of DP310, 10 parts of talc powder HS-768, 3 parts of rutile DuPont titanium dioxide, pigments are added according to the color requirements, and the mass ratio of the compound antioxidant is 1: 1 Compound, compound light stabilizer is a compound of low molecular weight hindered benzoate light stabilizer (Xinxiu Chemical 5586) and high molecular weight hindered amine light stabilizer (Xinxiu Chemical 901) with a mass ratio of 1:2 , the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com