Railway monolithic track bed with good shock absorption performance

An integral track bed, shock absorption technology, applied in springs/shock absorbers, roads, tracks, etc., can solve problems such as hidden safety hazards and poor shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

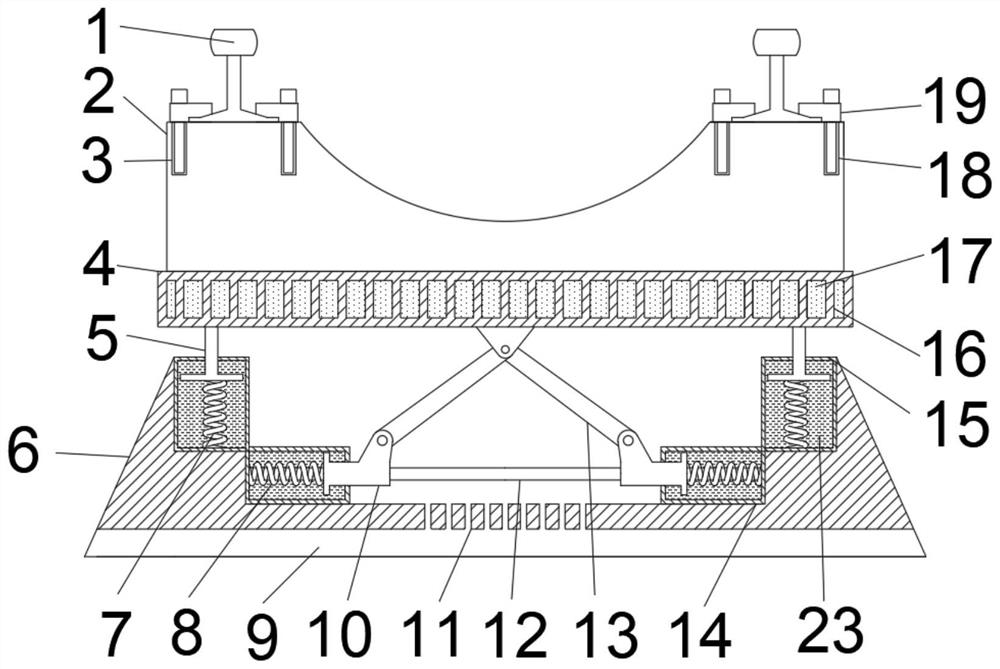

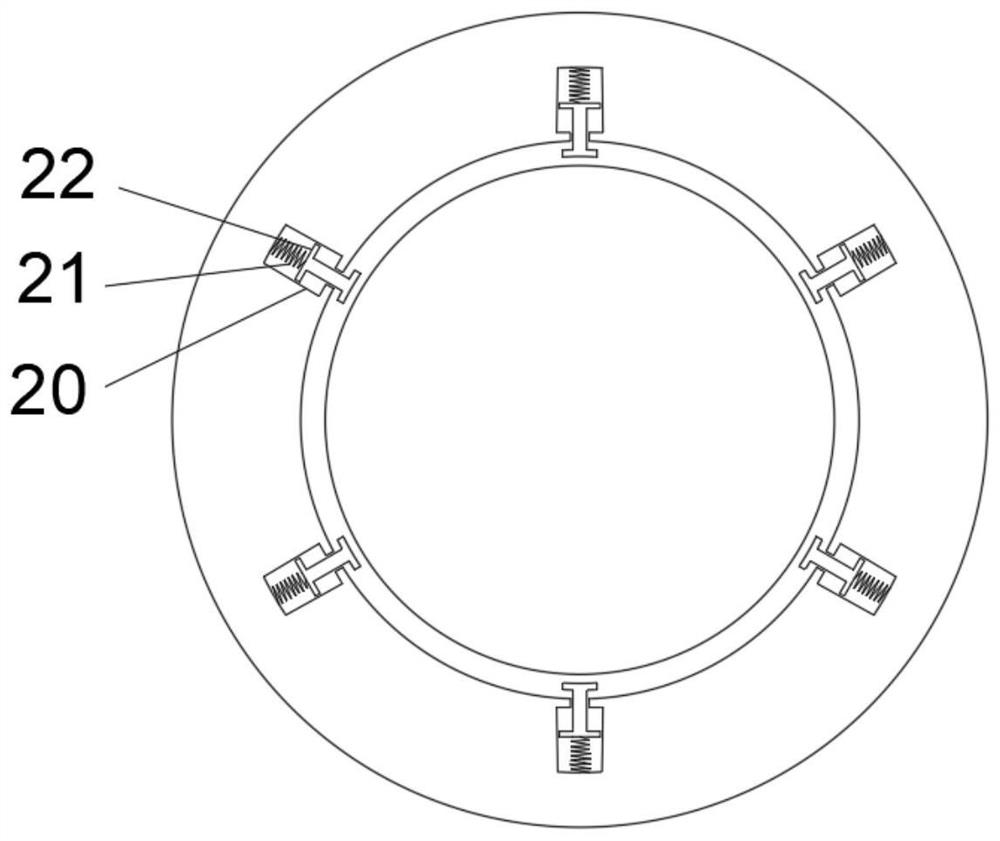

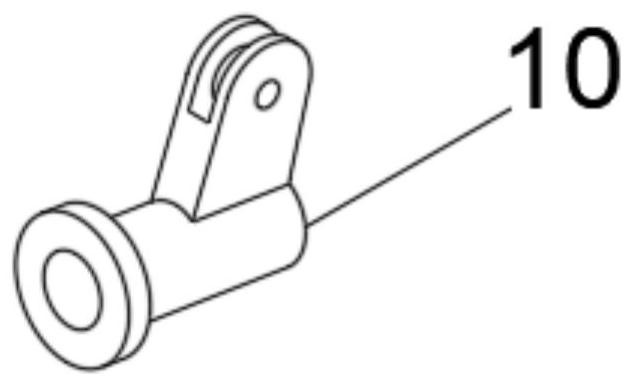

[0026] see Figure 1~3 , in an embodiment of the present invention, an integrated railway track bed with good shock absorption, comprising a sleeper 2, rails 1 are arranged on both sides above the sleeper 2, and rails 1 are fixedly connected to the sleeper 2 on both sides of the bottom of the rail 1 The installation block 19, the installation block 19 is provided with the installation bolt 3 that runs through the installation block 19; the position of the sleeper 2 corresponding to the installation bolt 3 is provided with a bolt hole 18; the bolt hole 18 and the installation bolt 3 are provided with The rail buffer mechanism, the rail buffer mechanism includes six mounting holes 20 evenly arranged in the bolt holes 18, the bottom of the mounting holes 20 is fixedly connected with a rail buffer spring 21, and the other end of the rail buffer spring 21 is connected to the The elastic shaft 22 is fixedly connected. When the train is running, it first contacts with rail 1, so the...

Embodiment 2

[0033]In this embodiment, a further improvement is made on the basis of Embodiment 1, and the improvement content is: a water channel 9 is provided at the bottom of the base 6 , and a water leakage port 11 is provided at the center of the base 6 . When running into rainy and snowy weather, sewage will enter inside the base, and the sewage will cause parts such as connecting rods and cross bars to corrode, thereby reducing their service life. And setting water channels and water leaks at the bottom can discharge it from the inside of the base in time, thereby avoiding parts from rusting.

[0034] To sum up, the working principle of the present invention is as follows: when the train is running, the train first passes the rail 1, and the rail 1 transmits the vibration to the mounting block and the mounting bolt, and the vibration is weakened for the first time by the rail buffer mechanism. Then the vibration is transmitted from the sleeper 2 to the base plate 4 and weakened for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com