Lower oscillation sliding vane jet flow stroke-increasing hydraulic oscillator

A hydraulic oscillator and jet technology, which is used in vibration drilling, vibration generating devices, wellbore/well components, etc., can solve the problems of short service life, complex structure, and many rotating parts, and achieve long service life and output efficiency. High, few moving parts effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

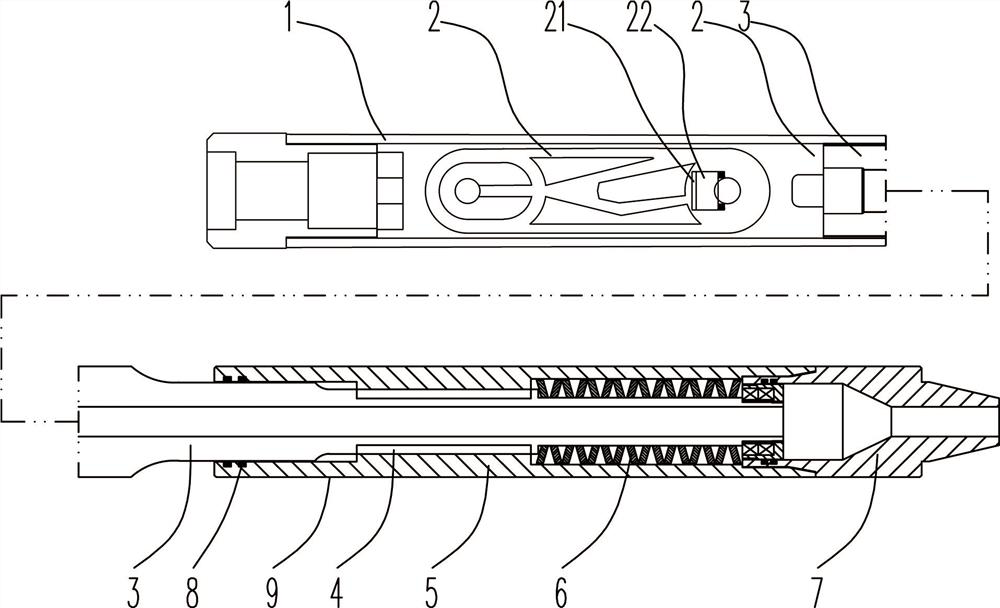

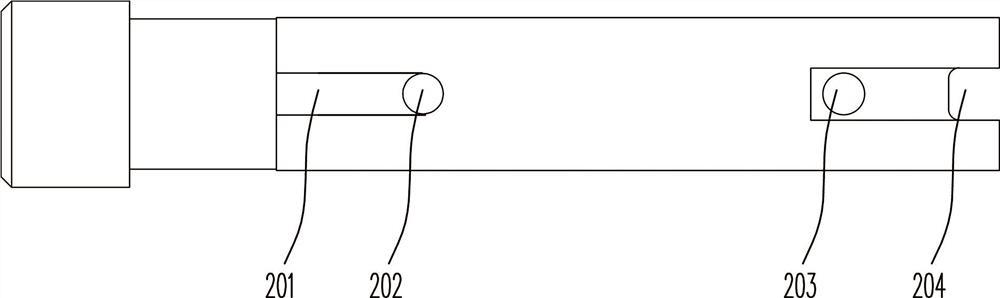

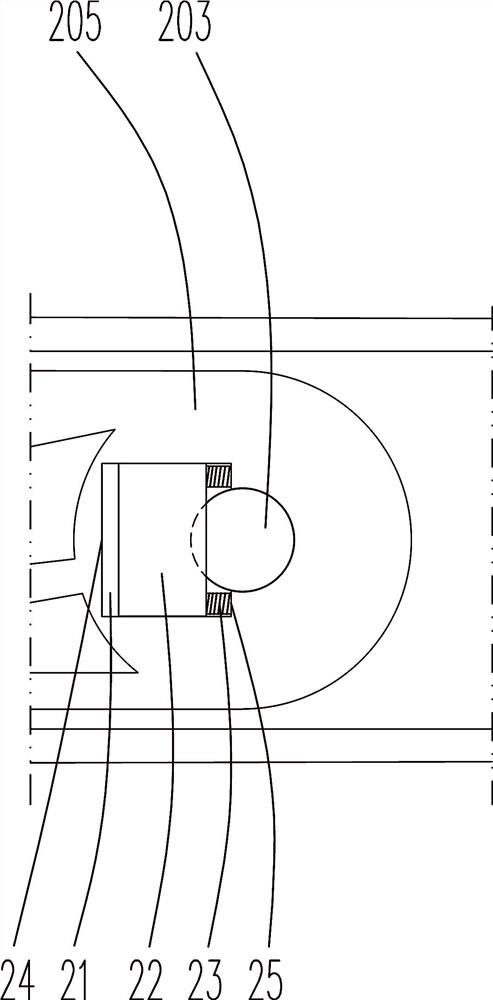

[0026] Such as Figure 1~4 Among them, a lower oscillating sliding vane jet flow extended range hydraulic oscillator, the outer sleeve 1 is fixed with a vortex cavity body 2, the vortex cavity body 2 is used to generate vibration, and an inlet hole 205 is provided at one end of the vortex cavity body 2, The other end of the vortex cavity body 2 is provided with an outlet hole 203, the outlet hole 203 is located at the center of the vortex cavity 205, and a chute 21 is provided on one side of the vortex cavity 203, and a slideway 21 is provided in the chute 21 to slide along the axial direction. One end of the stroke of the movable slider 22 partially covers the outlet hole 203 , and the other end of the stroke is completely away from the outlet hole 203 to alternately limit the flow section of the outlet hole 203 . Due to this structure, due to the vibration generated by the vortex cavity body 2, the vibration direction is along the axial direction of the outer sleeve 1, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com