Top-mounted structure of heat exchanger of electric regenerative furnace

A heat exchanger and electric heat storage technology, applied in heat exchange equipment, heating methods, electric heating systems, etc., can solve problems such as unfavorable system heat energy exchange effect, affecting the efficiency of electric heat storage furnace, affecting equipment safety and stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

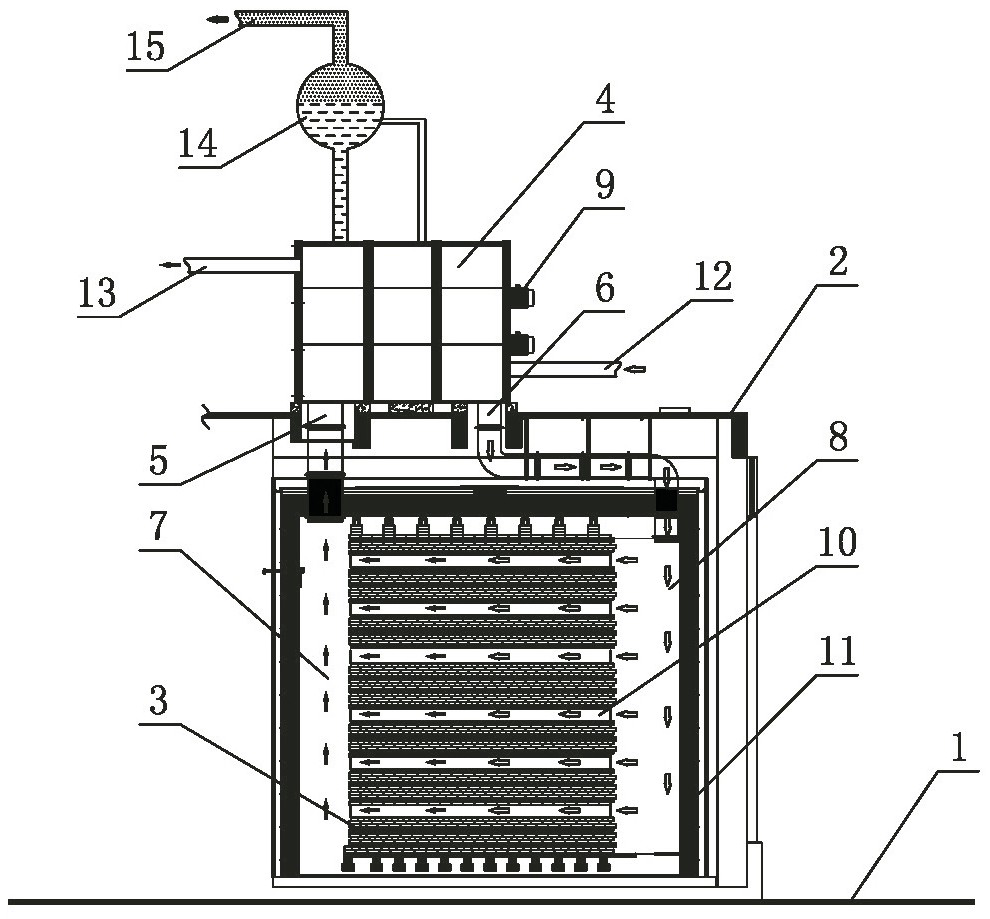

[0011] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The following descriptions are only for demonstration and explanation, and do not limit the present invention in any form.

[0012] like figure 1 As shown, 1 in the figure is a ground floor, 2 is a second floor floor, 3 is an electric heat storage body with a heat storage body insulation layer 11, a high temperature wind zone 7, and a low temperature wind zone 8, 4 is a heat exchanger, 9 is a circulating fan; the electric heat accumulator is set on the ground 1 on the first floor that meets the load requirements, and the light-weight heat exchanger 4 and the circulating fan 9 are placed on the second floor 2 on the top of the electric heat accumulator. The second-floor floor slab 2 has a structure with sufficient strength and bearing capacity, and is a second-floor floor slab with sufficient overall waterproof performance to prevent the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com