Thyroid puncture model based on 3D printing and manufacturing method thereof

A 3D printing and production method technology, applied in teaching models, auxiliary operations of additional layers, 3D object support structures, etc., can solve problems such as poor teaching practicability, hard materials, and poor simulation effects, and achieve convenient installation and promotion and application. , to achieve the effect of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In the following text, numerous specific details are set forth in order to provide a thorough understanding of the concepts underlying the described embodiments, however, it will be apparent to those skilled in the art that the described embodiments can be used without these specific details. Some or all instances were practiced, and in other instances well-known process steps were not described in detail.

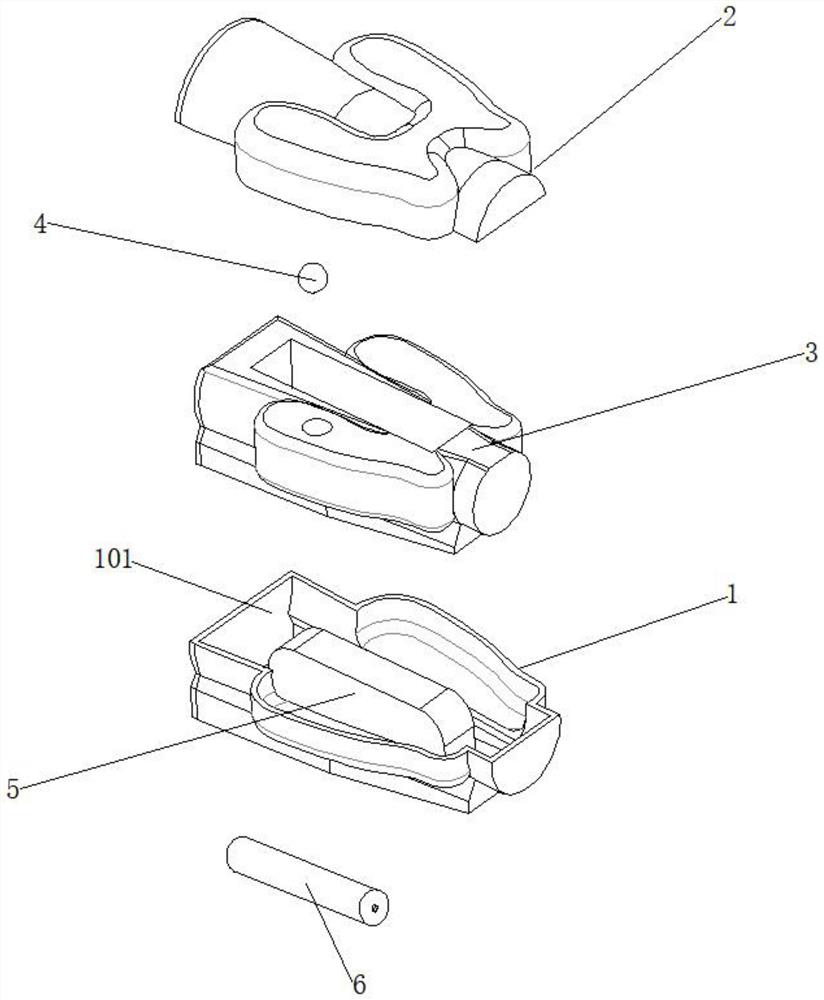

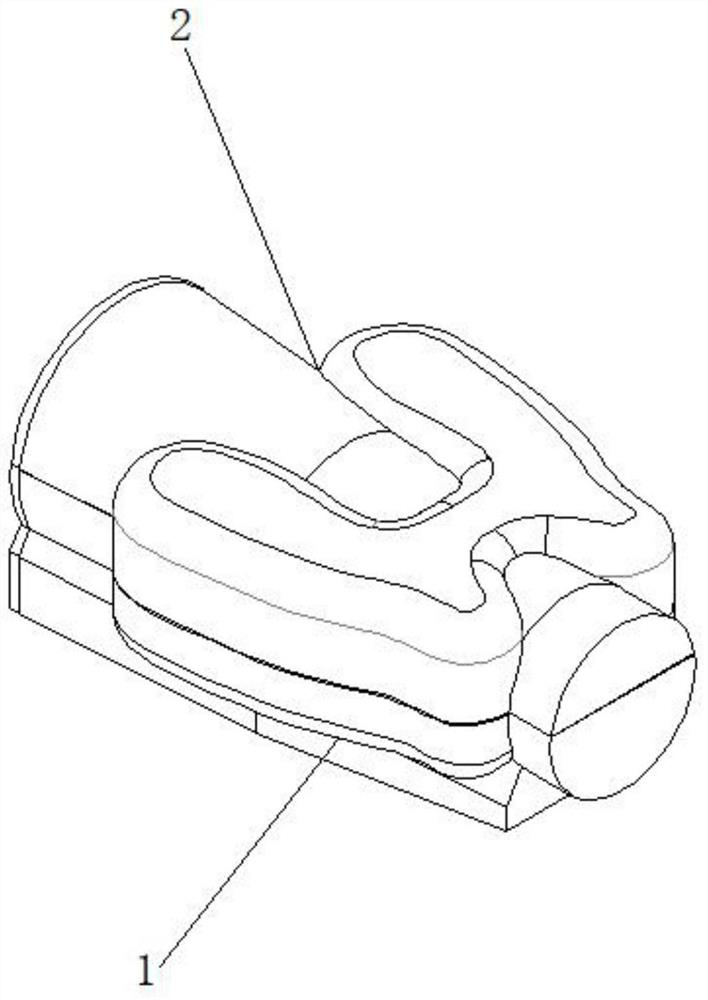

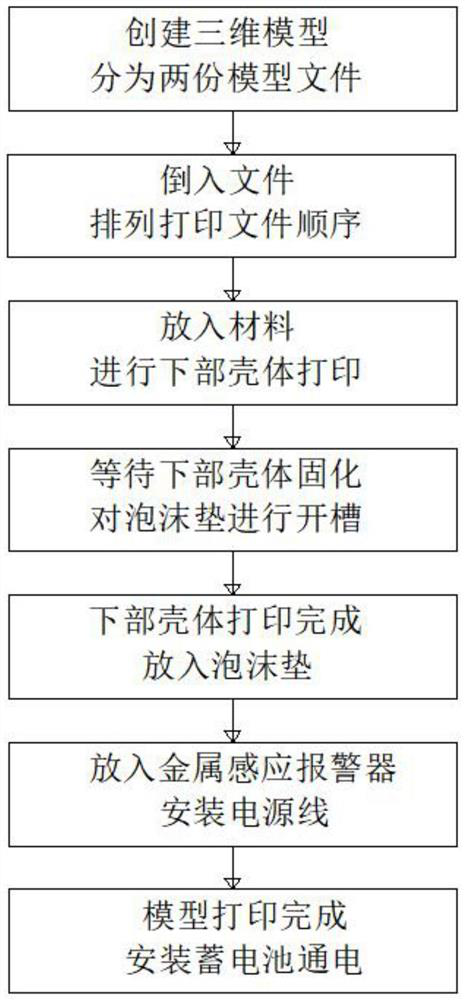

[0037] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, a thyroid puncture model based on 3D printing and its manufacturing method, the thyroid puncture model includes a lower casing 1, an upper casing 2, a foam pad 3, a metal induction alarm 4, a battery compartment 5, and a storage battery 6 , the upper shell 2 is fixed on the top of the lower shell 1, the upper shell 2 and the lower shell 1 are hot melt formed, and the lower shell 1 and the upper shell 2 are also placed inside Foam cushion 3, described foam cushion 3 ado...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com