Raw material wheat cleaning device for flour processing

A technology of cleaning device and feeding device, which is applied in application, grain processing, grain milling, etc., can solve the problems of inability to filter, fail to reach green environmental protection, waste water resources, etc., achieve novel internal structure design, facilitate classification, cleaning, and separation Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

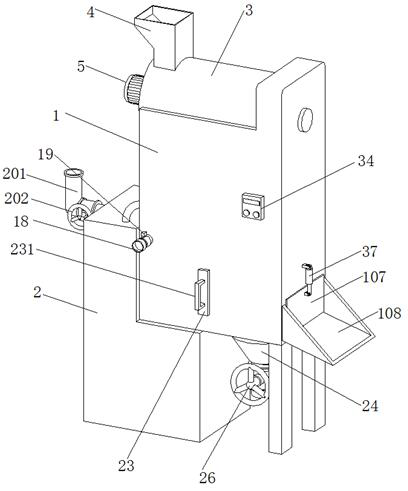

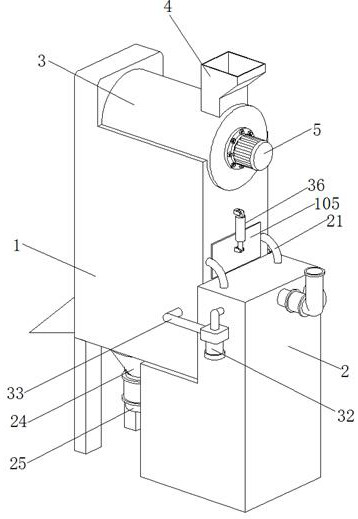

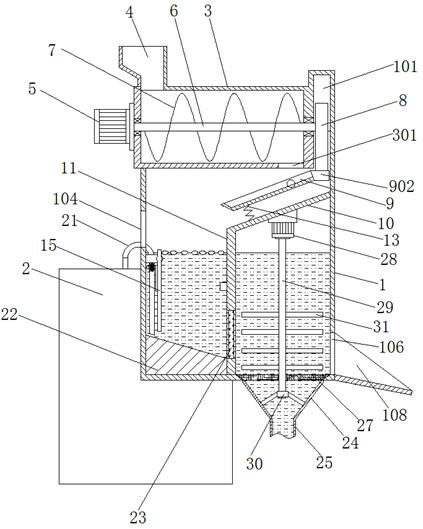

[0038] Embodiment 1 has introduced a kind of flour processing raw material wheat cleaning device, with reference to attached figure 1 And attached figure 1 , its main structure includes a cleaning tank 1 and a water storage tank 2, the water storage tank 2 is arranged on the left side of the cleaning tank 1, and a liquid feeding pipe 201 is arranged on the water storage tank 2, and a manual valve 202 is arranged on the liquid feeding pipe 201, The cleaning liquid can be replenished in the water storage tank 2 in time through the liquid feeding pipe 201 .

[0039] Reference attached image 3 And attached Figure 4 , the cleaning box 1 is provided with an auger uniform feeding device, specifically, its auger uniform feeding device includes a cylinder 3 arranged on the upper surface of the cleaning box 1, and a feeding hopper 4 is arranged on the upper surface of the left end of the cylinder 3, and the cleaning In the process, the wheat raw material purchased can be added to t...

Embodiment 2

[0046] Embodiment 2 is a further improvement and improvement made on the basis of Embodiment 1, which will be described in detail below with reference to the accompanying drawings.

[0047] First, the similarities between Embodiment 1 and Embodiment 2 will not be described again. The difference is that a PLC control panel 34 is also provided on the outer surface of the cleaning tank 1, and a liquid level sensor is provided on the vertical partition 11. 35, and the liquid level sensor 35 is electrically connected with the PLC control panel 34, and its liquid level sensor 35 detects the water level height during cleaning and feeds back to the PLC control panel 34, and the PLC control panel 34 controls the operation of the water pump 32 and Closed, so that the internal liquid level is at a reasonable height every time it is cleaned.

[0048]In addition, in order to further strengthen the sealing and waterproof performance between the first sealing side plate 105 and the floating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com