Waste metal pelleting machine

A technology of pelletizing machine and waste, which is applied in the field of waste metal recycling equipment, which can solve the problems of low processing capacity of metal pelletizing machine and irregular shape of metal pellets, and achieve the effect of saving internal space, occupying a large space, and reducing gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

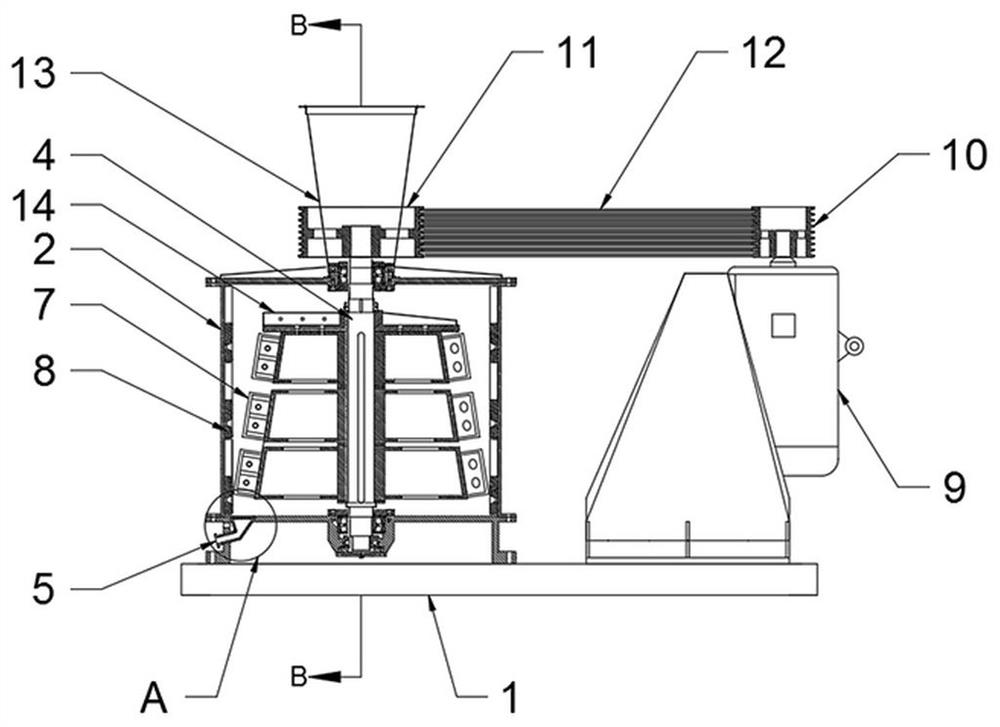

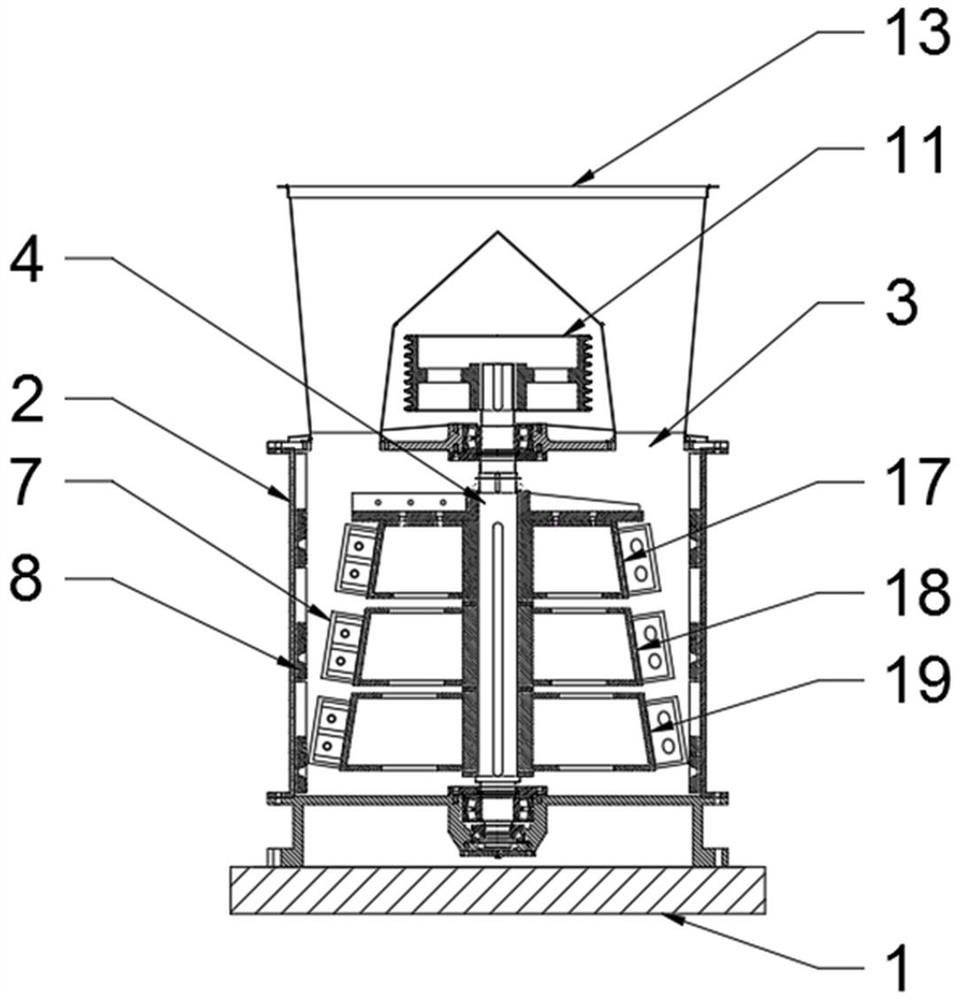

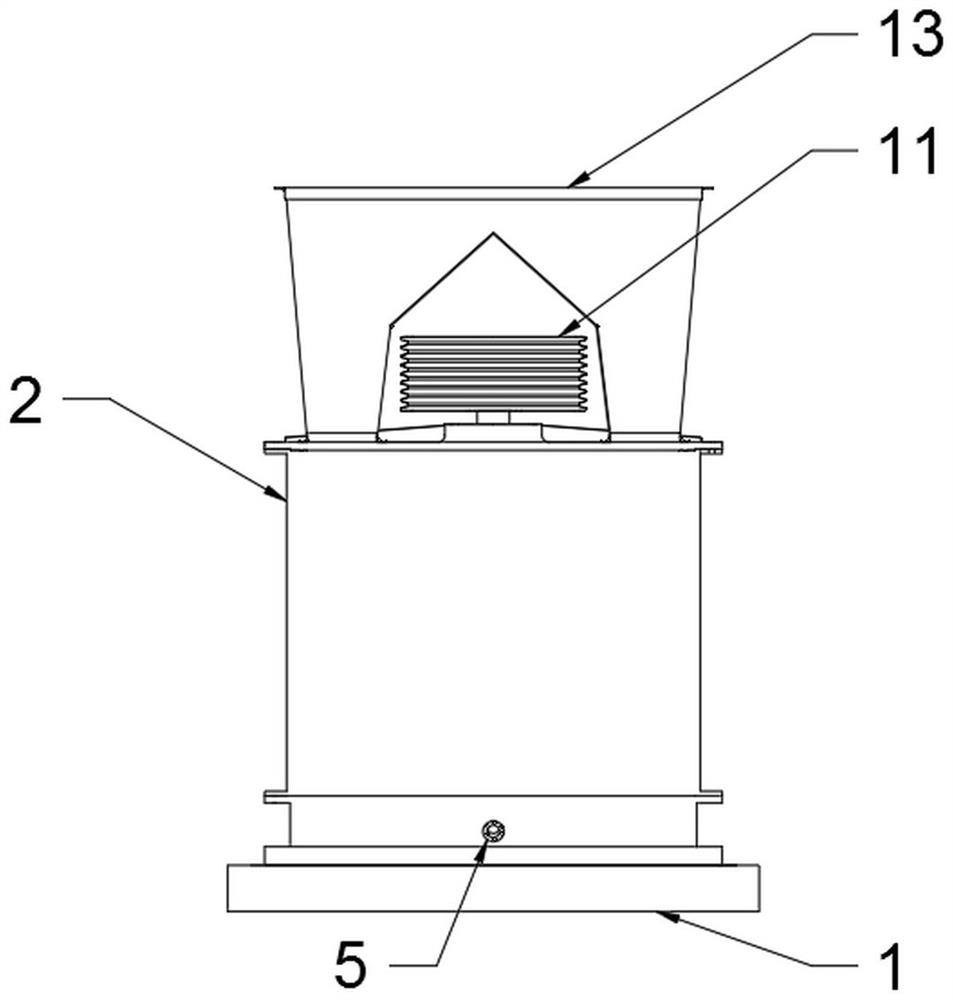

[0030] The metal scrap ball machine includes a base 1, a casing 2, and a driving device. The casing 2 is fixedly installed on the base 1. The casing 2 is cylindrical. The top of the casing 2 is provided with two feeding ports 3. The axis of the casing 2 is provided with a rotating shaft 4, and the two ends of the rotating shaft 4 are movably connected with the casing 2 through bearings. The driving device includes a driving motor 9, a driving wheel 10, a driven wheel 11, a transmission belt 12, a driving motor 9 and a base 1 Fixedly connected, the driving wheel 10 is fixedly installed on the rotating shaft of the driving motor 9, the driven wheel 11 is fixedly installed on the upper end of the rotating shaft 4, the driving wheel 10 and the driven wheel 11 are connected by power transmission belt 12, and the driving motor 9 uses a model of YX3-200L1 -2 high-power three-phase asynchronous AC motor, rated power 30kW, the bottom of the casing 2 is provided with a discharge port 5, ...

Embodiment 2

[0038] The metal scrap ball machine includes a base 1, a casing 2, and a driving device. The casing 2 is fixedly installed on the base 1. The casing 2 is cylindrical. The top of the casing 2 is provided with two feeding ports 3. The axis of the casing 2 is provided with a rotating shaft 4, and the two ends of the rotating shaft 4 are movably connected with the casing 2 through bearings. The driving device includes a driving motor 9, a driving wheel 10, a driven wheel 11, a transmission belt 12, a driving motor 9 and a base 1 Fixedly connected, the driving wheel 10 is fixedly installed on the rotating shaft of the driving motor 9, the driven wheel 11 is fixedly installed on the upper end of the rotating shaft 4, the driving wheel 10 and the driven wheel 11 are connected by power transmission belt 12, and the driving motor 9 uses a model of YX3-200L1 -2 high-power three-phase asynchronous AC motor, rated power 30kW, the bottom of the casing 2 is provided with a discharge port 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com