Plate polishing and edge sawing device for fire-fighting box body production line

A technology of production line and fire box, which is applied in the direction of machine tools suitable for grinding workpiece planes, machine tools suitable for grinding workpiece edges, grinding drive devices, etc., which can solve the problems of reducing labor intensity, prominent areas, and low safety factors, etc. problem, to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

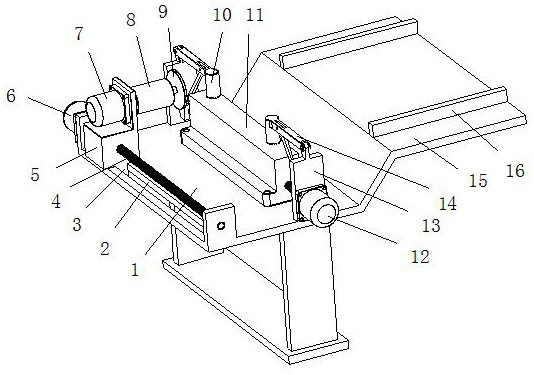

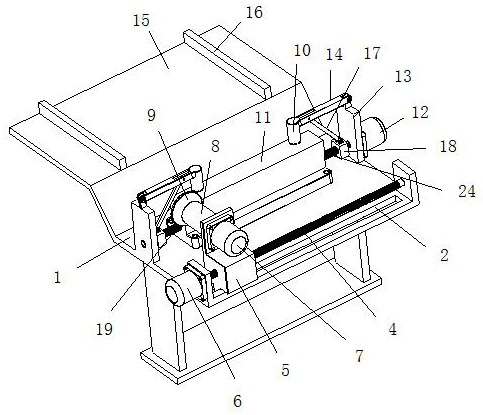

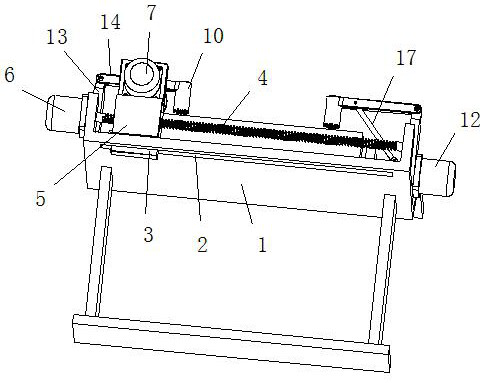

[0022] like Figure 1-4 As shown, a polishing and sawing device for plates used in the production line of fire box boxes includes a base 1 mounted on a bracket, and the base 1 is provided with a saw edge end for the plates to be polished to lie flat. The positioning plate 11, the base 1 is also provided with a clamping member for clamping and installing the end of the plate to be polished on the positioning plate 11, and the base 1 is provided with a slide that slides along the length direction of the positioning plate 11 Seat 5, the sliding seat 5 is driven by a translation piece to move horizontally, a polishing motor 7 is installed horizontally on it, and a self-adjusting part is driven and connected to the polishing motor 7, and a self-adjusting part is installed on the self-adjusting part. Polishing grinding wheel 9 for sawing and polishing, the self-adjusting part is used to make the polishing grinding wheel 9 have a moving stroke along its axial direction, so that the e...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap