Noise reduction equipment applied to pneumatic grinding machine

A pneumatic grinder and noise reduction technology, applied in the field of noise reduction, can solve problems such as secondary noise, different flow directions, pipe wall collision, etc., and achieve the effect of slow gas flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

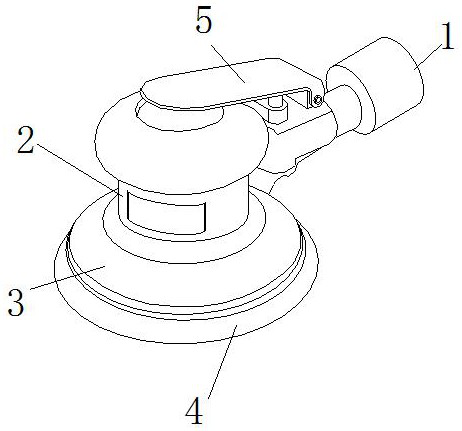

[0028] as attached figure 1 To attach Image 6 Shown:

[0029] The invention provides a noise reduction device applied to a pneumatic grinder, the structure of which includes an air inlet 1, a motor shield 2, a grinding shell 3, a grinding head 4, and a switch handle 5, and one end of the air inlet 1 is connected to the The outside of the motor casing 2 is connected, the grinding casing 3 is embedded and installed at the bottom of the motor casing 2, the grinding head 4 is movably connected to the bottom of the grinding casing 3, and one end of the switch pressure handle 5 is connected to the air intake The top of port 1 is connected, and the switch pressure handle 5 moves above the motor shield 2.

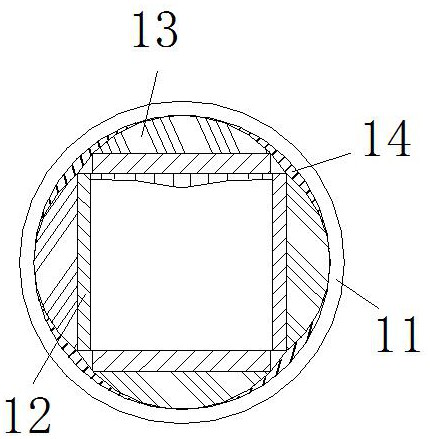

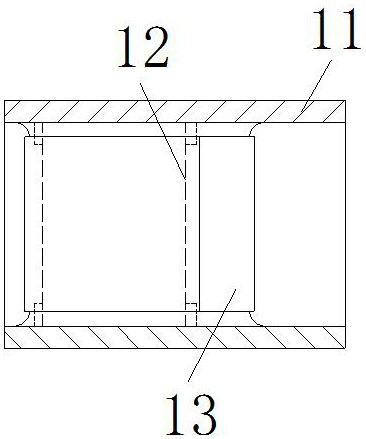

[0030] The air inlet 1 is provided with a pipe 11, a noise reducer 12, a petal block 13, and a corner block 14, the noise reducer 12 is located in the middle of the inner side of the pipe 11, and the outer wall of the petal block 13 is connected to the On the inner side wall of...

Embodiment 2

[0036] as attached Figure 7 to attach Figure 8 Shown:

[0037] Wherein, the corner block 14 is provided with a retaining flap b1, an angle stabilizing end b2, and a stabilizing layer b3, the retaining flap b1 is embedded and connected on the inner upper wall of the corner resisting block 14, and the corner stabilizing end b2 is fixed Installed under the retaining flap b1, the stabilizing layer b3 is connected to both sides of the angle-stabilizing end b2, the retaining flap b1 is in the shape of an ellipse to ensure uniform stress, and the overall shape of the angle-stabilizing end b2 is fixed at It can return to its original shape after stretching.

[0038] Wherein, the stabilizing layer b3 is provided with a pointed insertion section b31, an inner pressure layer b32, a supporting arc block b33, an inner buttress b34, and a pocket b35, and the pointed insertion section b31 is located at the center of the stabilizing layer b3. At the most side angle position, the stretchi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com