Method for guiding robot to suck buzzers for dust removal

A robot and buzzer technology, which is applied to the cleaning methods, chemical instruments and methods, cleaning methods and utensils using gas flow, etc. Improved assembly efficiency and high alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

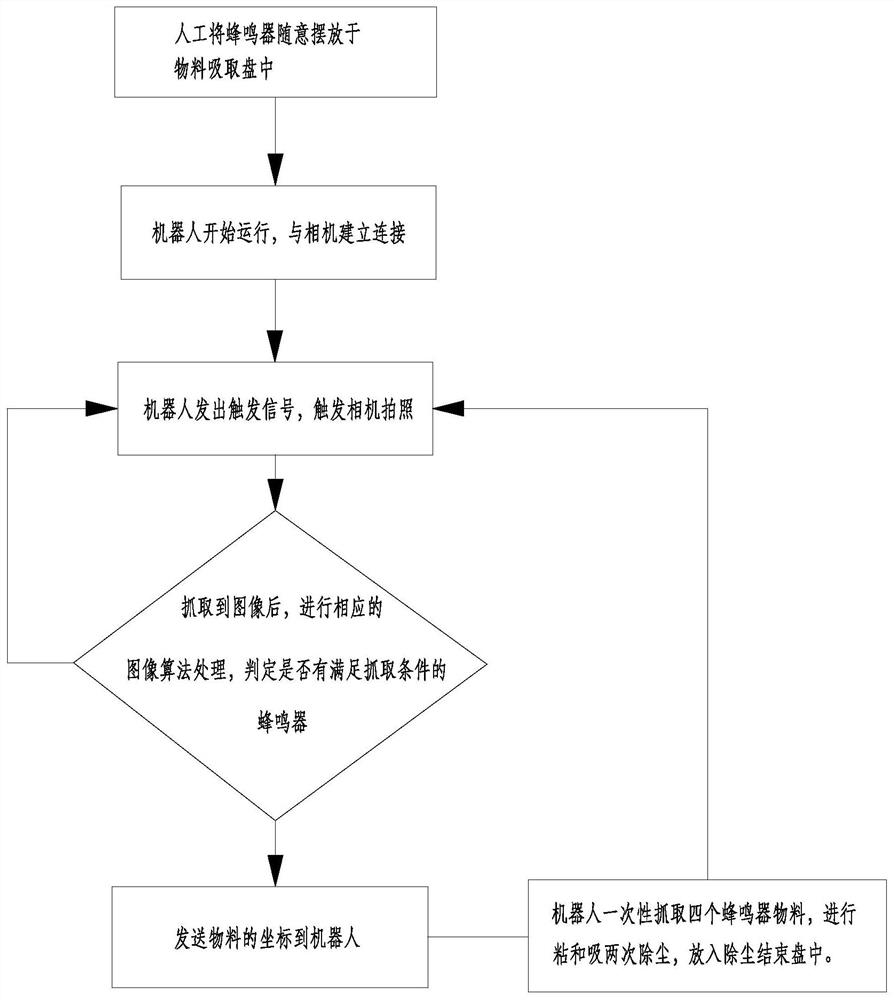

[0015] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0016] Such as figure 1 Shown, a kind of method for guiding robot suction buzzer to carry out dust removal has the following steps:

[0017] S1: Manually place the buzzer in the material suction tray; more than 120pcs of material can be put in at one time, and the robot will start the running program and establish a Socket communication connection with the camera;

[0018] S2: The robot starts to run and establishes a communication connection with the camera; the robot sends a fixed camera command through Socket communication to trigger the camera to take pictures.

[0019] The above-mentioned camera is fixedly installed above the suction plate, and the phot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com