Mechanical arm for mine

A technology of a mechanical arm and a mechanical swing arm, applied in the field of mechanical arms, can solve the problems of violent shaking of the mechanical arm, potential safety hazards, laborious drilling, etc., to achieve stability without drilling, stable swing process, and increase the force on the bottom area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

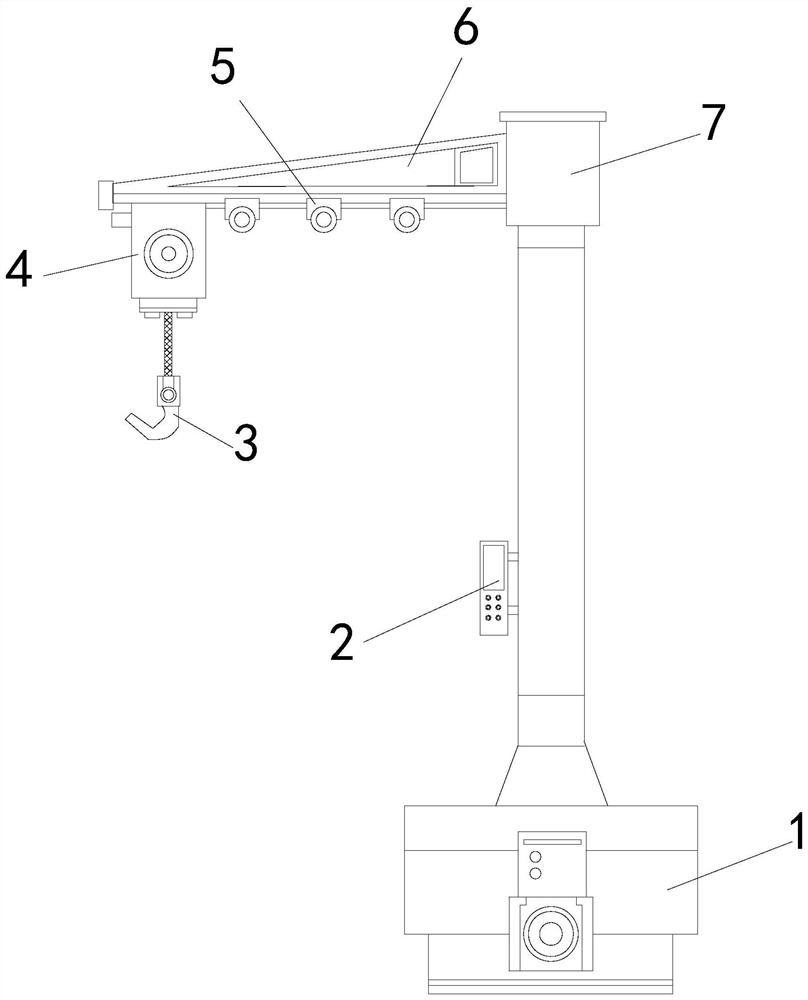

[0026] see Figure 1-Figure 3 , the present invention provides a mechanical arm technical solution for mines: its structure includes: a fixed frame body 1, a controller 2, a hoisting head 3, a power crane 4, a transmission shaft wheel 5, a mechanical swing arm 6, and a supporting main rod 7 , the hoisting head 3 is installed under the power crane 4 and fastened with the power crane 4, the power crane 4 is arranged under the mechanical swing arm 6, and the mechanical swing arm 6 is locked with the power crane 4, The power hoist 4 is electrically connected to the controller 2 through the transmission shaft wheel 5, the controller 2 is arranged at the lower end of the supporting main rod 7, and a fixed frame body 1 is arranged below the supporting main rod 7, and the fixed frame body 1 is locked with the supporting main rod 7, and the fixed frame body 1 includes a support plate device a, a stability maintenance device b, a buffer pad c, an assembly steel frame d, and a connection...

no. 2 example

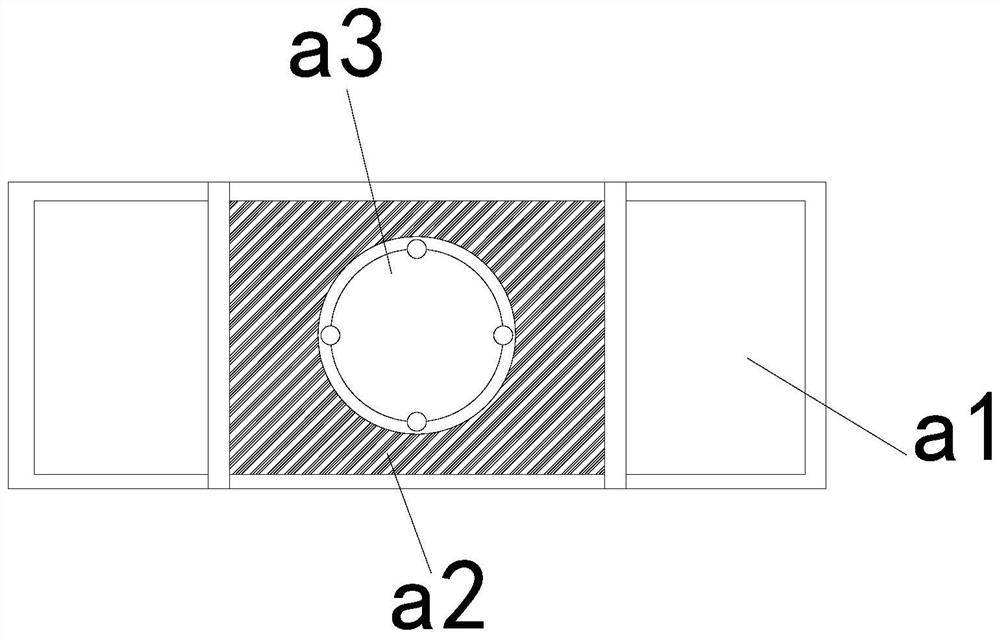

[0030] see Figure 4-Figure 6 , the present invention provides a mechanical arm technical solution for mines: its structure includes: the adjustment plate device a1 includes an adjustment shaft tube a11, a side slide plate a12, a locking plate a13, and a connecting sleeve layer a14, and the inside of the side slide plate a12 is provided with There is a locking plate a13 and it is welded with the locking plate a13. The inner side of the locking plate a13 is provided with an adjustment shaft tube a11. The inner side of the adjustment shaft tube a11 is provided with a connection sleeve layer a14. The gap between the connection sleeve layer a14 and the adjustment shaft tube a11 Cooperate.

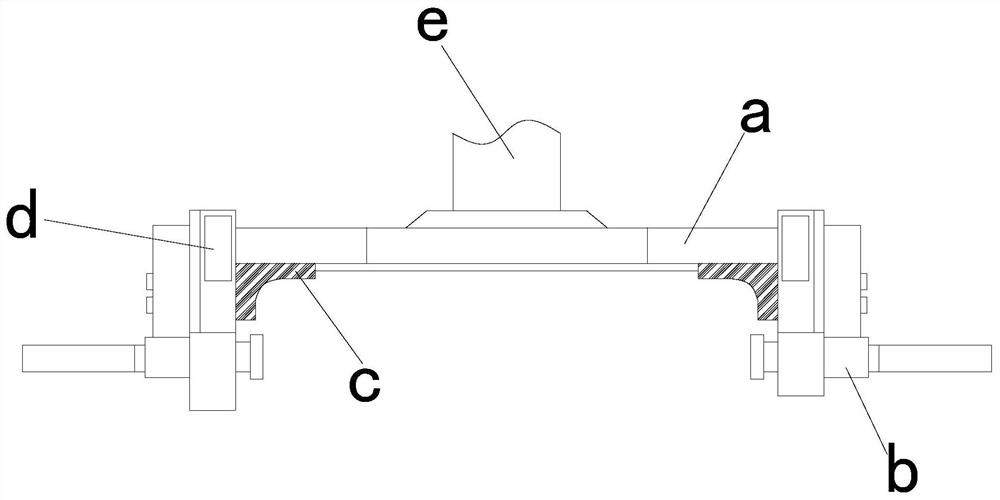

[0031] The stability maintenance device includes a snap-fit frame device b1, an electric storage tube b2, a telescopic shaft b3, and a travel motor b4. The snap-fit frame device b1 is installed on the front end of the telescopic shaft b3, and the telescopic shaft b3 runs through the travel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com