Responsive concrete antifreeze agent as well as preparation method and application thereof

A technology of concrete and antifreeze, which is applied in the direction of applying stable tension/pressure to test material strength, instruments, and analysis materials, etc. It can solve the problems of negative impact on mechanical properties, many limiting factors in use, complex construction, etc., and achieve the use method The effect of simplicity, fewer restrictions on use, and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

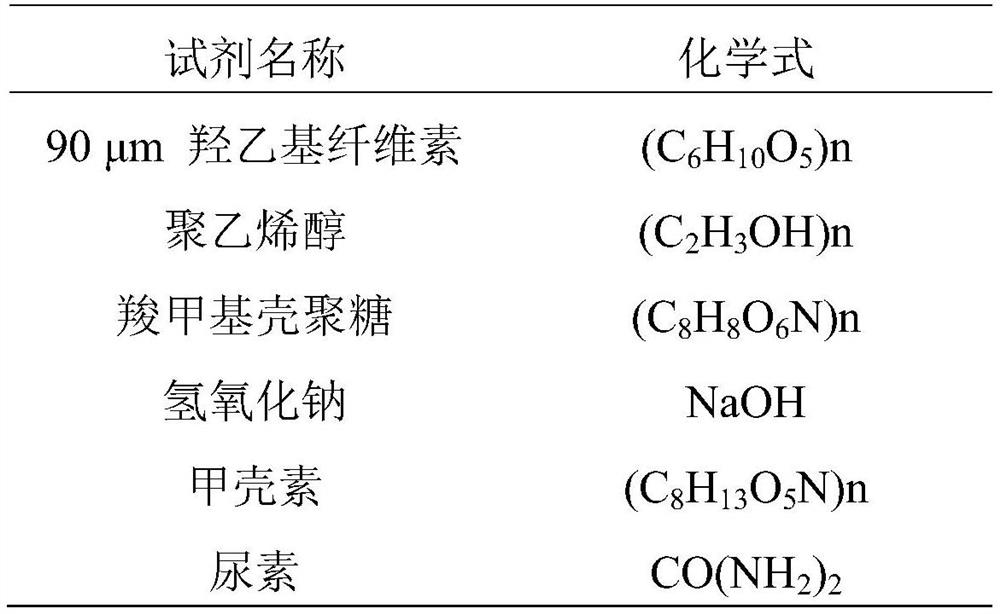

[0036] A responsive concrete antifreeze agent, the main raw materials are carboxylated chitosan, hydroxyethyl cellulose, chitin, polyvinyl alcohol, urea and sodium hydroxide, as shown in Table 1 below:

[0037] Table 1 Reagents used in the test

[0038]

[0039] According to the proportioning design of antifreeze, the former solution obtains the following table 2:

[0040] Table 2 Ratio design of antifreeze original solution

[0041]

[0042] Above-mentioned cellulose / chitosan former solution and PVA / chitin former solution are uniformly mixed, can make antifreeze, select two formulas (mass ratio) of preparation antifreeze, as shown in table 3:

[0043] Table 3 Antifreeze ratio

[0044]

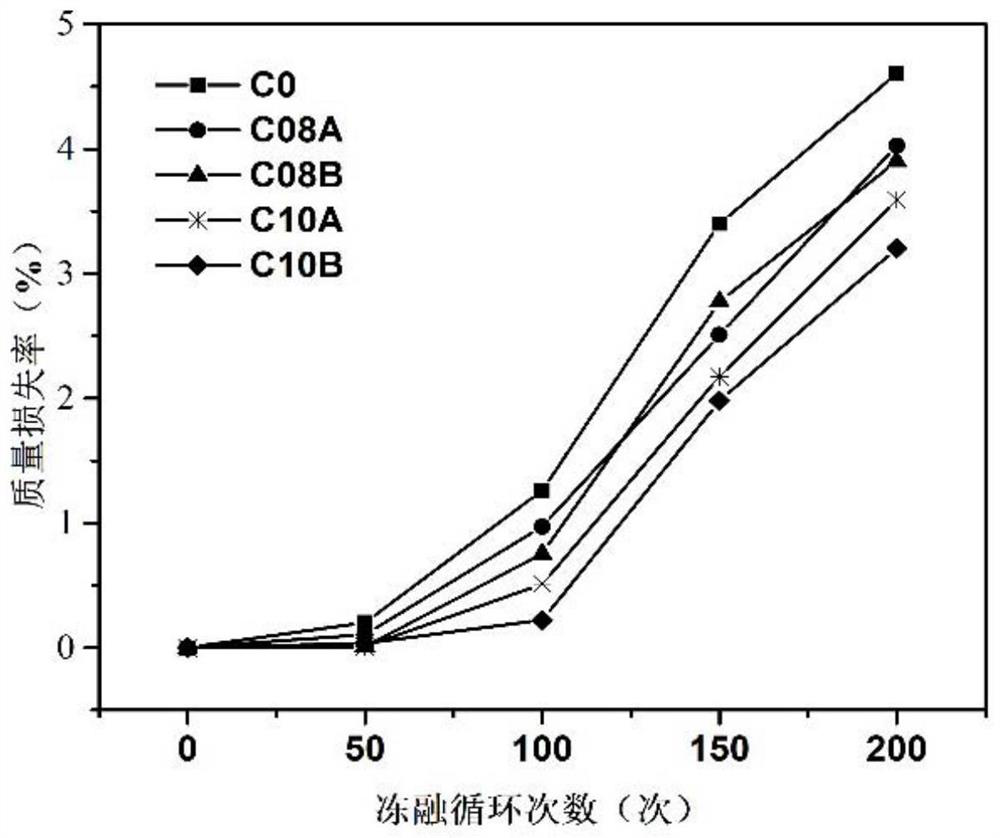

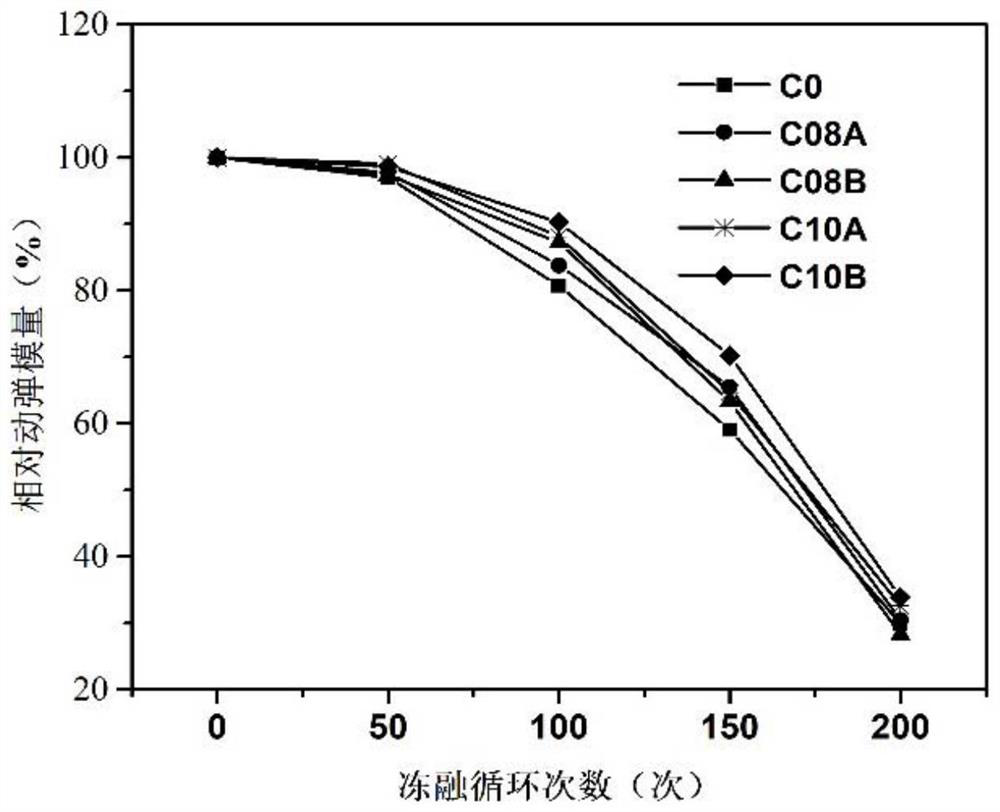

[0045]Raw materials used to prepare ordinary concrete: P.O 42.5 ordinary Portland cement; natural river sand, medium sand with a fineness modulus of 2.7, and all indicators meet the requirements of the "Sand for Construction" (GB / T14684-2011) standard specification; The pebbles wit...

Embodiment 2

[0062] A kind of responsive concrete antifreeze, its preparation method comprises the following steps:

[0063] 1) adding NaOH and urea to water to obtain NaOH / urea solution;

[0064] 2) Add hydroxyethyl cellulose and carboxylated chitosan to NaOH / urea solution to obtain cellulose / chitosan solution; add polyvinyl alcohol and chitin to NaOH / urea solution to obtain polyvinyl alcohol / chitin solution;

[0065] 3) Mix the cellulose / chitosan solution with the polyvinyl alcohol / chitin solution evenly and remove air bubbles to obtain the responsive concrete antifreeze agent.

[0066] In step 1), in the NaOH / urea solution, the solvent is water, the mass percentage of NaOH is 1%, and the mass percentage of urea is 5%.

[0067] In step 2), the preparation process of the cellulose / chitosan solution is as follows: adding hydroxyethyl cellulose to the NaOH / urea solution at 35°C and stirring, then adding carboxylated chitosan and ultrasonically dispersing , followed by freezing and thawi...

Embodiment 3

[0078] A kind of responsive concrete antifreeze, its preparation method comprises the following steps:

[0079] 1) adding NaOH and urea to water to obtain NaOH / urea solution;

[0080] 2) Add hydroxyethyl cellulose and carboxylated chitosan to NaOH / urea solution to obtain cellulose / chitosan solution; add polyvinyl alcohol and chitin to NaOH / urea solution to obtain polyvinyl alcohol / chitin solution;

[0081] 3) Mix the cellulose / chitosan solution with the polyvinyl alcohol / chitin solution evenly and remove air bubbles to obtain the responsive concrete antifreeze agent.

[0082] In step 1), in the NaOH / urea solution, the solvent is water, the mass percentage of NaOH is 3%, and the mass percentage of urea is 3%.

[0083] In step 2), the preparation process of the cellulose / chitosan solution is as follows: adding hydroxyethyl cellulose to the NaOH / urea solution at 45°C and stirring, then adding carboxylated chitosan and ultrasonically dispersing , followed by freezing and thawi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com