Pulverized coal flow regulating valve of boiler air and powder pipeline and control method of pulverized coal flow regulating valve

A flow regulating valve, regulating valve technology, applied in the direction of valve lift, valve details, valve devices, etc., can solve the problems of insufficient mixing of air powder, uneven air powder, unsatisfactory combustion conditions, etc., to improve coal powder Effects of distribution ratio, increasing output of pulverized coal, and reducing carbon content in fly ash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

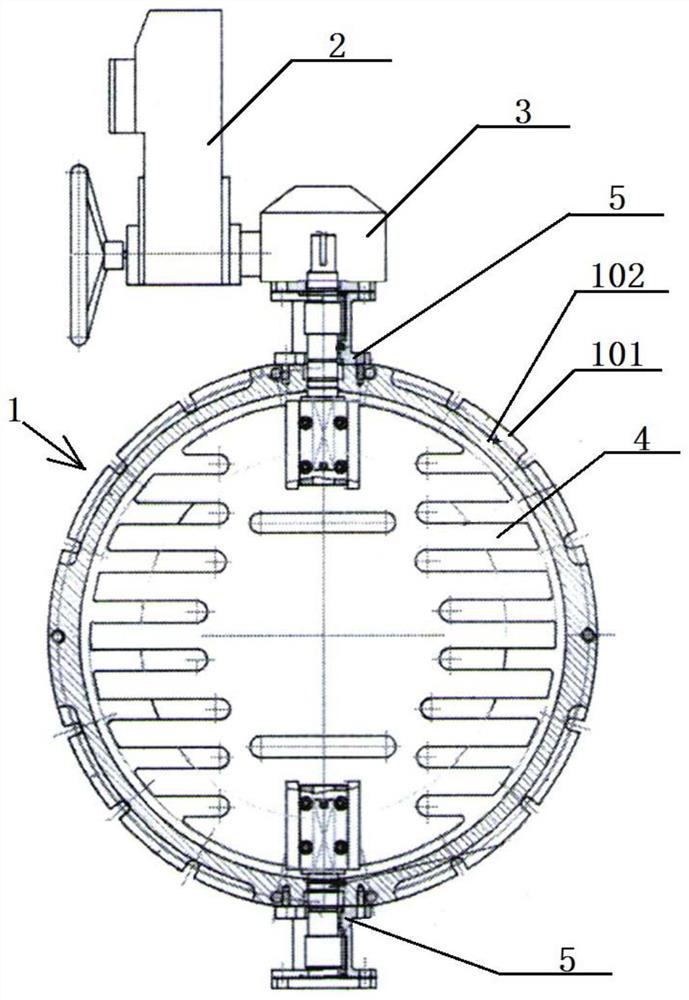

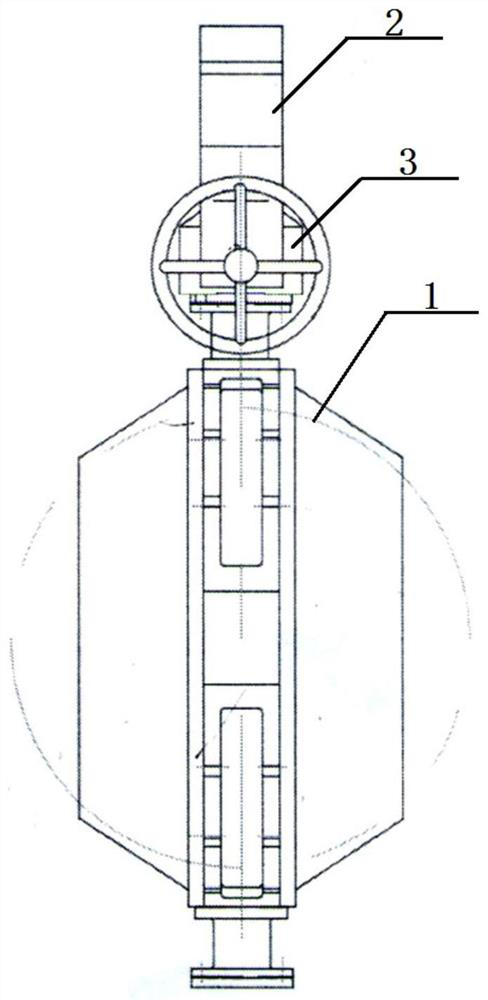

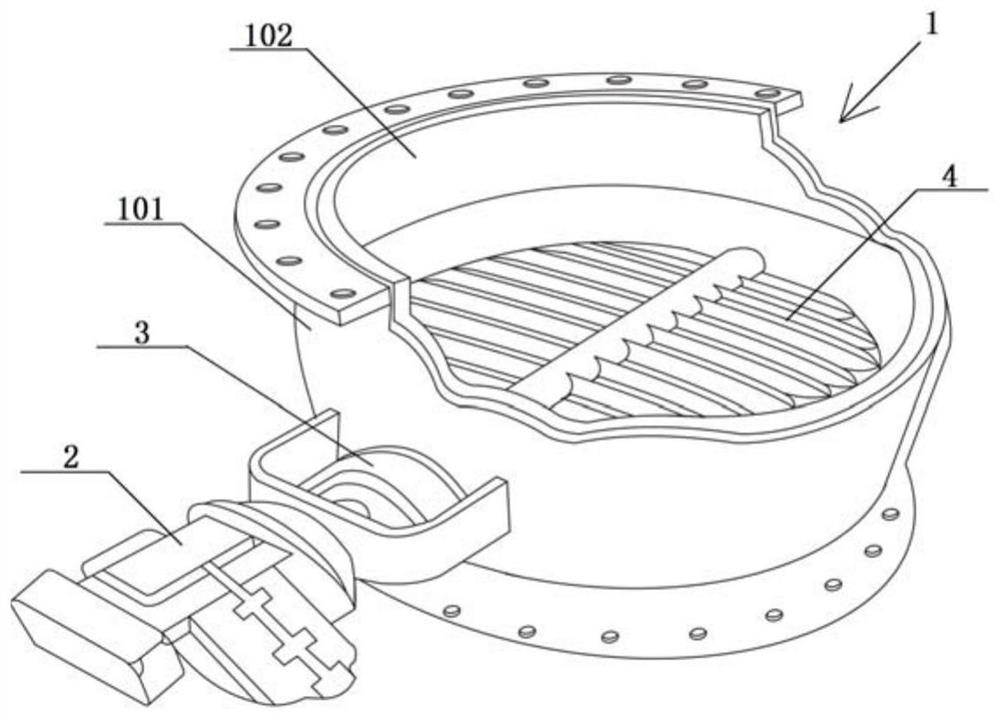

[0031] refer to Figure 1-4 , the pulverized coal flow regulating valve of the boiler air powder pipeline provided by the present invention includes: a coal mill and several pulverized coal pipelines connected with the pulverizer, and several pulverized coal pipelines connected with the pulverizer A pulverized coal flow regulating valve is arranged between the pipelines, and the pulverized coal flow regulating valve includes: a regulating valve body 1, a permanent magnet servo actuator 2 installed on the casing of the regulating valve body 1, and a spur gear reducer 3, Rotate the double-comb valve plate 4 connected inside the regulating valve body 1, the bearing seat 5 installed on the regulating valve body 1 and located on both sides of the double-comb valve plate 4, wherein the regulating valve body 1 It includes: an outer casing 101 and a sealed casing 102 attached to the inner wall of the outer casing 101. Flanges are arranged at both ends of the outer casing 101, and the ...

Embodiment 2

[0037] This embodiment provides a method for controlling the powder flow state of a pulverized coal flow regulating valve of a boiler air powder pipeline, which specifically includes the following steps:

[0038] Step S1: install a pulverized coal flow regulating valve 1 between the pulverized coal mill and several pulverized coal pipelines connected to the pulverized coal mill, and control the pulverized coal flow state through the pulverized coal flow regulating valve 1;

[0039] Step S2: using the double-comb valve plate 4 inside the pulverized coal flow regulating valve 1 to divide the regulating valve body 1 into a front chamber and a rear chamber;

[0040] Step S3: Using the pulverized coal flow regulating valve 1 whose inner diameter is larger than that of the pulverized coal pipeline, the pulverized coal flow through the pulverized coal pipeline is blocked by the damping action of the central blocking plate 401 of the double-comb valve plate 4, and the pulverized coal f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com