A Method for Lubricating Oil Temperature Control of Large Condenser Condenser Suppressing Intermittent Internal Disturbance

A temperature control method and lubricating oil technology, which is applied in the direction of engine lubrication, lubricating parts, mechanical equipment, etc., can solve problems such as unfavorable lubricating oil temperature stability control, internal disturbance of fan start and stop, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to clarify the technical scheme and working principle of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

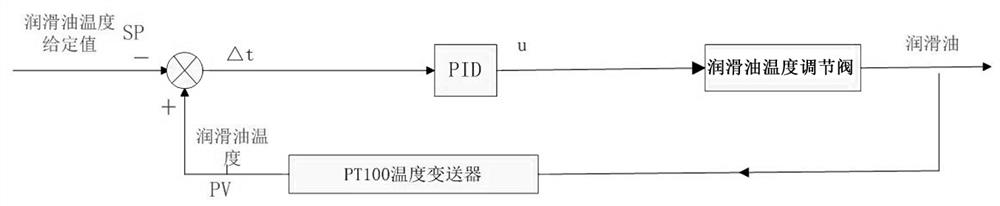

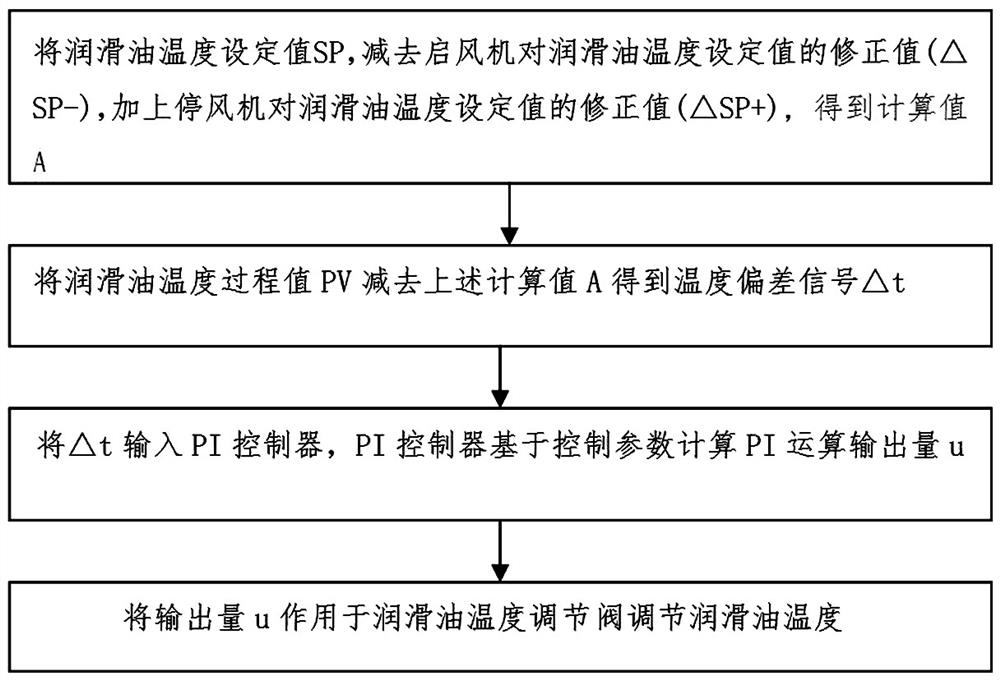

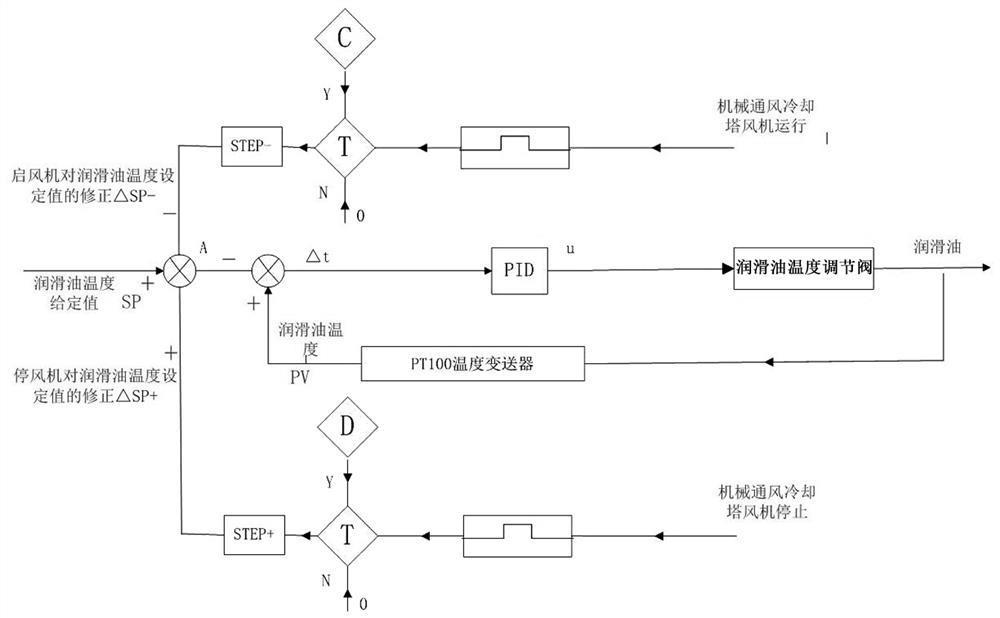

[0035] Such as figure 2 , image 3 A large-scale condenser lubricating oil temperature control method that suppresses intermittent internal disturbance is shown, which is used in the control of the lubricating oil temperature regulating valve by the PID controller of the lubricating oil system. The heated lubricating oil maintains an appropriate oil temperature by exchanging heat with the external cooling water in the heat exchanger. The lubricating oil temperature regulating valve is installed on the water inlet pipe of the external cooling water of the heat exchanger, and the water inlet flow of the external cooling water pipe of the heat exchanger is controlled through the opening degree, so as to realize the adjustment of the outlet oil temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com