Construction method and application of specific electrochemical sensor for HER2 detection

A construction method and electrochemical technology, applied in the field of electrochemistry, can solve problems such as composite materials that are rarely reported, and achieve the effects of promoting cross-development, expanding applications, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

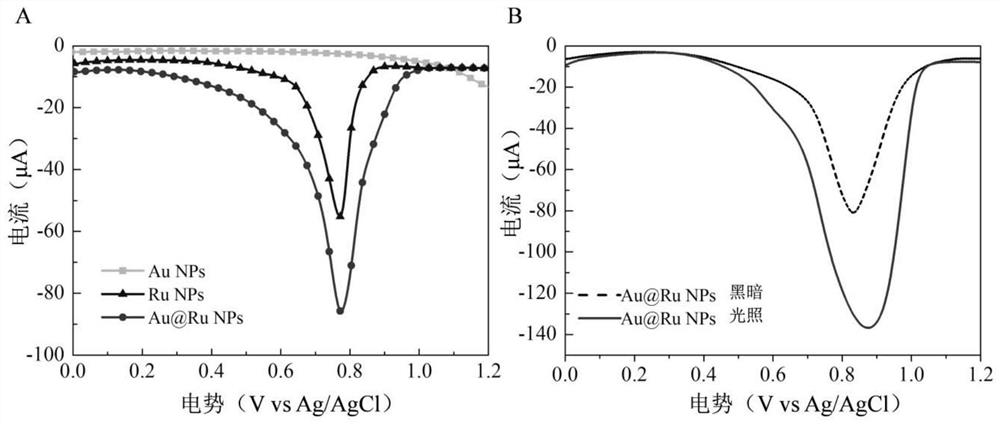

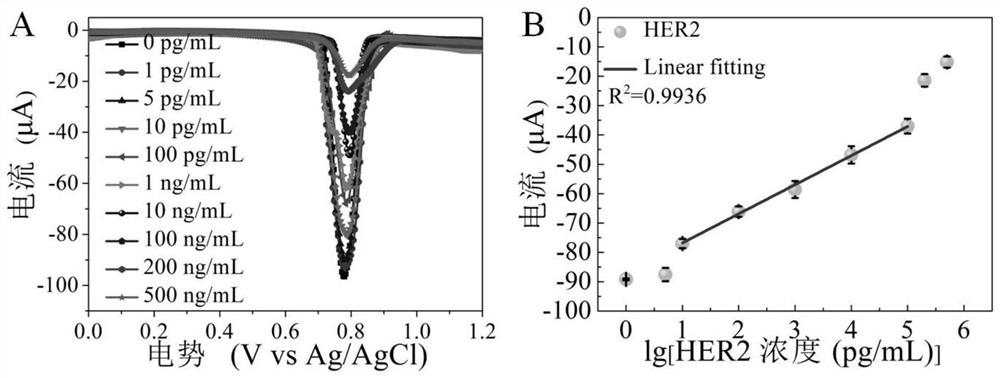

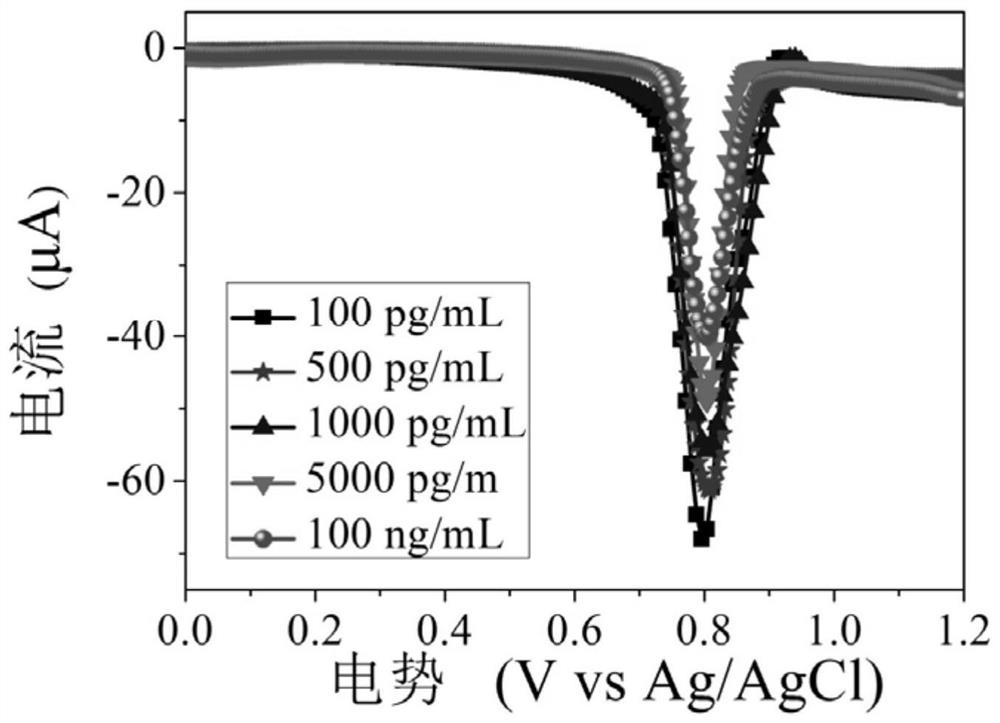

Method used

Image

Examples

Embodiment 1

[0033] A method for constructing a specific electrochemical sensor for HER2 detection, specifically comprising the steps of:

[0034] (1) Preparation of AuRu nanoparticles:

[0035] First, PVP (80 mg) and CTAB (60 mg) were dissolved in 15 mL of diethylene glycol solution, and the solution was stirred at room temperature for 20 minutes. It was then placed in a sand bath and heated at 190° C. for 5 minutes with magnetic stirring. Immediately after, 30 mg CTAB and 5 mg RuCl 3 ·3H 2 O was dispersed in 1 mL of diethylene glycol. Then, 20 μL of an ethanol solution of chloroauric acid (0.05 g / mL) was added to the above mixture with stirring. Afterwards, the mixed solution was injected into the previously heated diethylene glycol solution through a flow syringe pump. Subsequently, the solution was heated at a temperature of 190° C. for 5 minutes under magnetic stirring, and the color of the solution was observed to change to dark brown. After the solution was cooled to room temp...

Embodiment 2

[0048] A method for constructing a specific electrochemical sensor for HER2 detection, specifically comprising the steps of:

[0049] (1) Preparation of AuRu nanoparticles:

[0050] First, PVP (88.8 mg) and CTAB (72.9 mg) were dissolved in 20 mL of diethylene glycol solution, and the solution was stirred at room temperature for 30 minutes. It was then placed in a sand bath and heated at 195° C. for 10 minutes with magnetic stirring. Immediately after, 36mg CTAB and 7.8mg RuCl 3 ·3H 2 O was dispersed in 2 mL of diethylene glycol. Then, 24.2 μL of an ethanol solution of chloroauric acid (0.1 g / mL) was added to the above mixture with stirring. Afterwards, the mixed solution was injected into the previously heated diethylene glycol solution through a flow syringe pump. Subsequently, the solution was heated at a temperature of 195° C. for 10 minutes under magnetic stirring, and the color of the solution was observed to change to dark brown. After the solution was cooled to ro...

Embodiment 3

[0063] A method for constructing a specific electrochemical sensor for HER2 detection, specifically comprising the steps of:

[0064] (1) Preparation of AuRu nanoparticles:

[0065] First, PVP (100 mg) and CTAB (80 mg) were dissolved in 25 mL of diethylene glycol solution, and the solution was stirred at room temperature for 40 minutes. It was then placed in a sand bath and heated at 2000 °C for 15 minutes with magnetic stirring. Immediately after, 40mg CTAB and 10mg RuCl 3 ·3H 2 O was dispersed in 3 mL of diethylene glycol. Then, 30 μL of an ethanol solution of chloroauric acid (0.15 g / mL) was added to the above mixture with stirring. Afterwards, the mixed solution was injected into the previously heated diethylene glycol solution through a flow syringe pump. Subsequently, the solution was heated at a temperature of 200° C. for 15 minutes under magnetic stirring, and the color of the solution was observed to change to dark brown. After the solution was cooled to room te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com