A catalyst evaluation device for CO dehydrogenation purification with reaction gas recycling and controllable atmosphere

A technology for purifying catalysts and reactive gases, applied in measuring devices, control/regulating systems, non-electrical variable control, etc., it can solve problems such as changing the ratio of reaction raw materials, and the inability to realize gas recycling, reducing the proportion of Gas cycle, the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

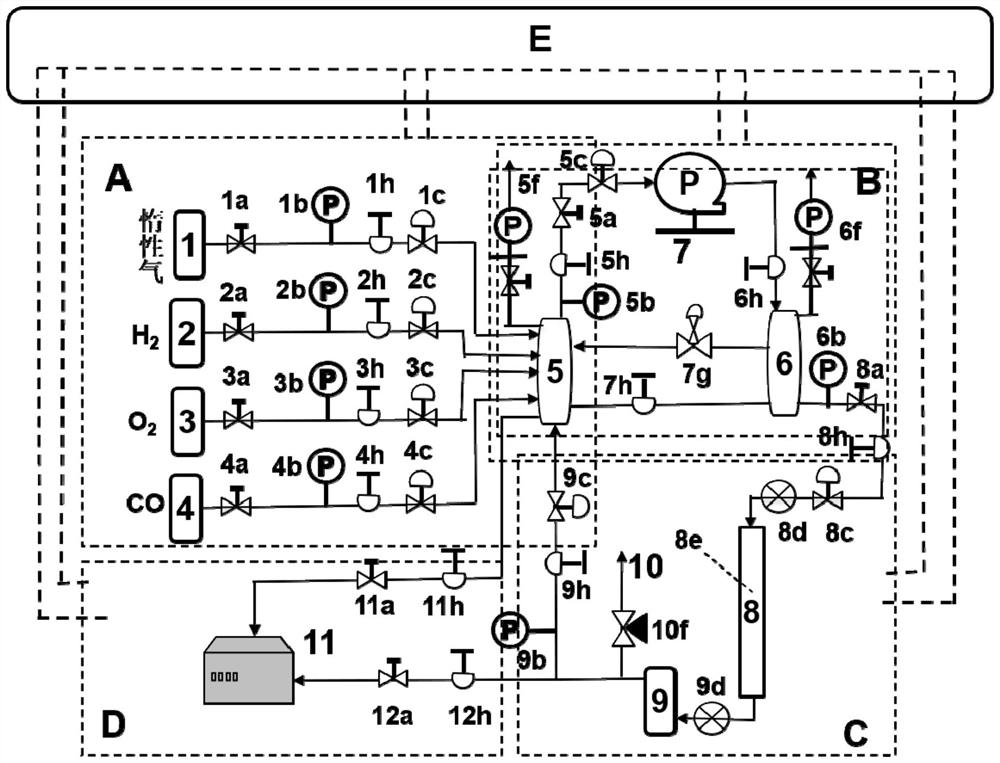

[0052] (1) Check the airtightness of the device.

[0053] (2) Measure 100ml of CO dehydrogenation purification catalyst and load it into reactor 8, insert thermocouple 8e into the midpoint of the catalyst bed, and connect the front and back pipes of reactor 8.

[0054] (3) Close the second shut-off valve 2h, the third shut-off valve 3h, the fourth shut-off valve 4h, the fifth shut-off valve 5h, the sixth shut-off valve 6h, the ninth shut-off valve 9h, the eleventh shut-off valve 11h, the twelfth shut-off valve Stop valve 12h, open the first pressure stabilizing valve 1a, the first stop valve 1h, the first mass flow meter 1c, the seventh stop valve 7h, the eighth stop valve 8h, the eighth mass flow meter 8c, and the ninth mass flow meter 9c 8. The eighth pressure stabilizing valve 8a, adjust the valve opening of the differential pressure flowmeter 7g to 0, unscrew the back pressure valve 10f completely, and let in nitrogen gas to purge the system, control the flow rate of nitro...

Embodiment 2

[0061] According to the steps of Example 1, what are specifically adjusted are steps (3), (7) and (8), and steps (1), (2), (4), (5), and (6) remain unchanged.

[0062] Adjust step (3) to: close the second cut-off valve 2h, the third cut-off valve 3h, the fourth cut-off valve 4h, the fifth cut-off valve 5h, the sixth cut-off valve 6h, the ninth cut-off valve 9h, and the eleventh cut-off valve 11h, the twelfth stop valve 12h, open the first pressure stabilizing valve 1a, the first stop valve 1h, the first mass flow meter 1c, the seventh stop valve 7h, the eighth stop valve 8h, the eighth mass flow meter 8c, the first Nine mass flowmeter 9c, eighth pressure stabilizing valve 8a, adjust the valve opening of the differential pressure flowmeter 7g to 0, unscrew the back pressure valve 10f completely, blow in nitrogen gas to purge the system, and control the flow rate of nitrogen gas to 800ml / min, after purging for 10 minutes, open the ninth shut-off valve for 9 hours, tighten the b...

Embodiment 3

[0066] According to the steps of Example 1, what are specifically adjusted are steps (3), (7) and (8), and steps (1), (2), (4), (5), and (6) remain unchanged.

[0067] Adjust step (3) to: close the second cut-off valve 2h, the third cut-off valve 3h, the fourth cut-off valve 4h, the fifth cut-off valve 5h, the sixth cut-off valve 6h, the ninth cut-off valve 9h, and the eleventh cut-off valve 11h, the twelfth stop valve 12h, open the first pressure stabilizing valve 1a, the first stop valve 1h, the first mass flow meter 1c, the seventh stop valve 7h, the eighth stop valve 8h, the eighth mass flow meter 8c, the first Nine mass flowmeter 9c, eighth pressure stabilizing valve 8a, adjust the valve opening of the differential pressure flowmeter 7g to 0, unscrew the back pressure valve 10f completely, let nitrogen gas in to purify the system, and control the flow rate of nitrogen gas to 1000ml / min, after purging for 10 minutes, open the ninth shut-off valve for 9 hours, tighten the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com