Composite stone face tile

A stone surface and multiple technology, applied in the field of multiple synthetic stone surface tiles, can solve the problems of high cost, difficult bonding, low surface gloss, etc., and achieve the effects of low cost, easy color matching, and consistent color and luster.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

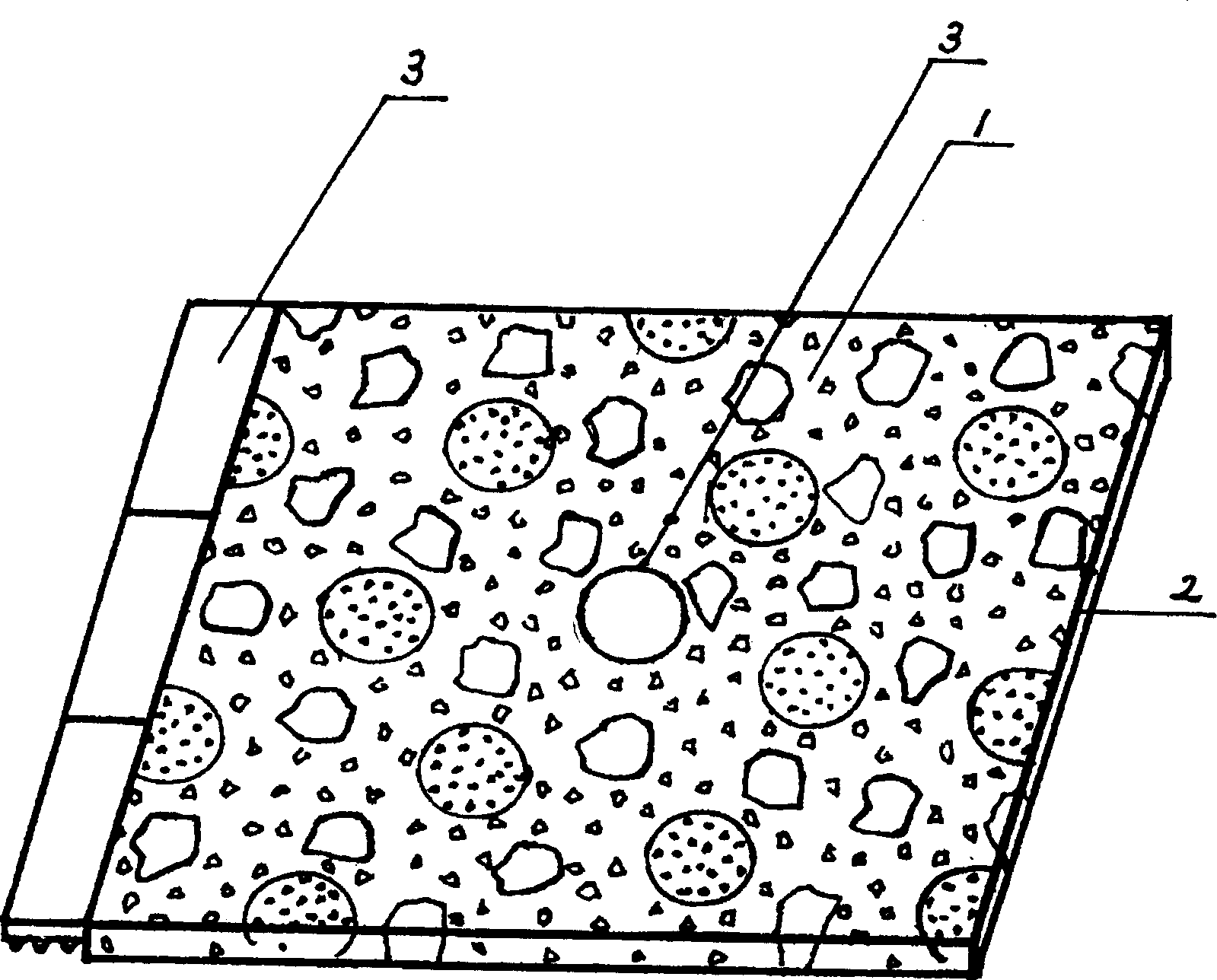

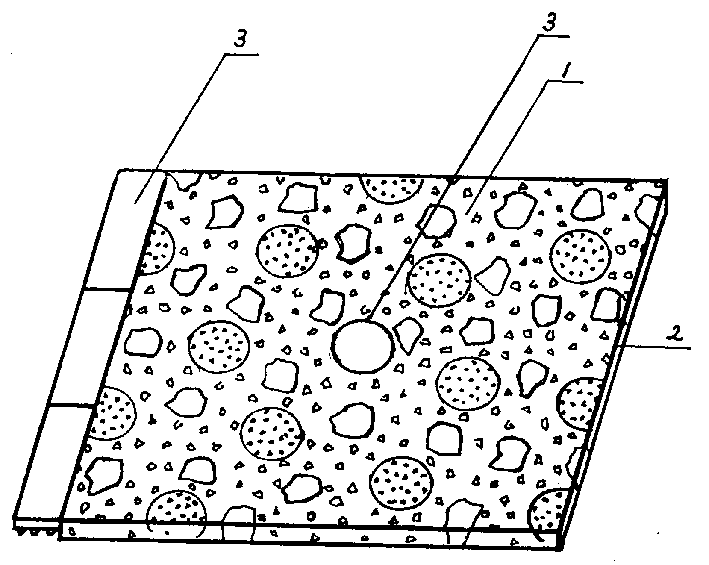

[0008] The implementation of the present invention can be produced by making certain technical improvements in the existing complete artificial stone production line and glass mosaic production line. The attached picture is a schematic diagram of the assembly of synthetic stone facing bricks and three attached composite glasses. The production process of the products is as follows:

[0009] ① Prefabricated cement body production: use 70% by weight of 0-2mm marble fine sand processed by crushed stone, 30% by weight of organic pigment, 107 glue, water and white cement to mix into agglomerates. For the production of strong artistic shapes, it can also be made into rolls by hand, layer by layer, and then pressed with a mold with a certain shape. The body of this example is a circular sphere with a diameter of 60 mm;

[0010] ② Manufacture of glassy complex (3): This product can be mass-produced after the improvement of the existing glass mosaic production line. Stone spreading d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap