Miniaturized high-power isolated synthetic network device and implementation method

A technology of a network device and an implementation method, applied in the field of communication, can solve the problems of unsatisfactory amplitude and phase consistency of multiple branches, failure to consider isolation, and large inter-stage influence, and achieve good performance characteristics, compact structure, and withstand power. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A method for realizing a miniaturized high-power isolated synthesis network, including steps:

[0055] Step S1: providing a lower chamber 1 and an upper chamber 2;

[0056] Step S2: Carry out milling on the opposite sides of the lower cavity 1 and the upper cavity 2, including:

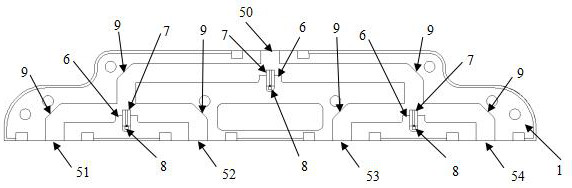

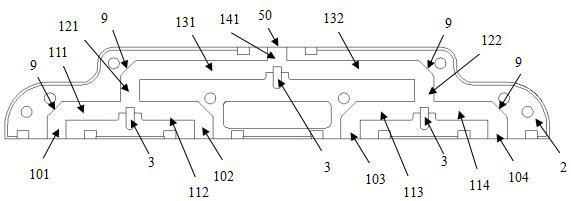

[0057] The corresponding positions on the opposite side are all processed: No. 101 of the first vertical channel I, No. 102 of the first vertical channel II, No. 103 of the first vertical channel III, No. 104 of the first vertical channel IV, and No. 111 of the first horizontal channel , No. 112 of the first horizontal channel II, No. 113 of the first horizontal channel III, No. 114 of the first horizontal channel IV, No. 121 of the second vertical channel I, No. 122 of the second vertical channel II, No. 131 of the second horizontal channel I, No. Second horizontal channel II No. 132, third vertical channel 141;

[0058] The ends of the first vertical channel No. I 101, the first vertical ch...

Embodiment 2

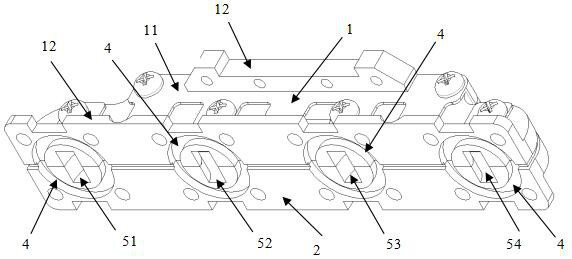

[0072] Such as Figure 1~4 As shown, this example provides a miniaturized high-power isolated composite network device, including: a cavity, and the composite network device is formed in the cavity.

[0073] The cavity body includes a lower cavity 1 and an upper cavity 2 that cooperate with each other. Specifically, the synthetic network device is formed on the mutual mating surface of the lower cavity 1 and the upper cavity 2, and the lower cavity 1 and the upper cavity 2 are locked by fasteners after being matched.

[0074] The miniaturized high-power isolated synthetic network device of this example includes:

[0075] E-arm branch waveguide port I No. 51, E-arm branch waveguide port II No. 52, E-arm branch waveguide port III No. 53, and E-arm branch waveguide port IV No. 54 arranged at equal intervals along a straight line;

[0076] The first vertical channel I No. 101, the first No. 102 of vertical channel II, No. 103 of first vertical channel III, No. 104 of first verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com