Brushless direct-drive linear servo actuator

A linear actuator and direct drive technology, applied in the direction of electromechanical devices, electrical components, magnetic circuit static parts, etc., can solve the problem that the application environment cannot guarantee reliability and life, cannot meet high reliability, high precision and low cost, The motor cannot realize stroke displacement feedback control and other problems, so as to achieve the effects of simple and reliable processing and assembly, improved system bearing capacity, and low manufacturing and use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

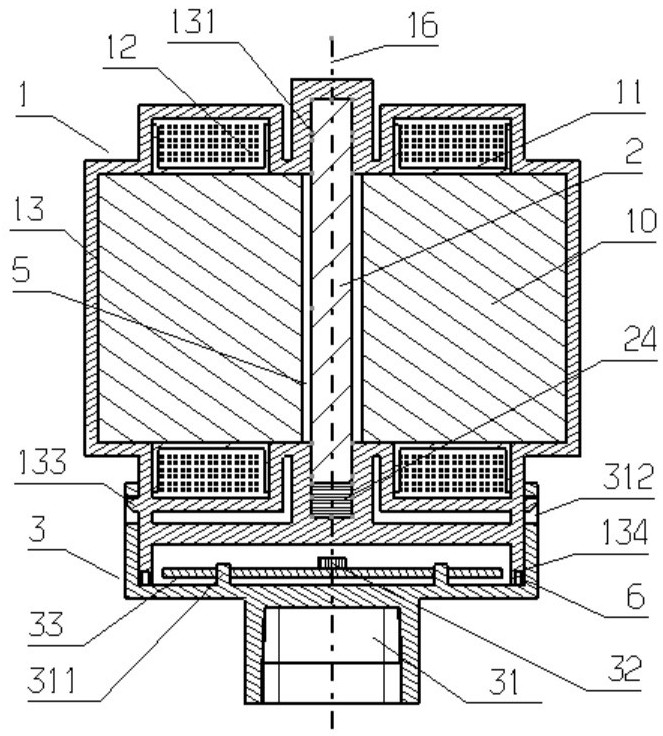

[0036] Figure 5 It is the B-B plane sectional view of the brushless direct-drive linear servo actuator of the first embodiment of the present invention. The specific implementation method is as follows: two groups of armatures are integrally covered by the shell 13 to form a solid integrated structure. The mover chamber 131 and the output hole 132 for extending the output end 23 are formed in the shell 13. The two sides of the mover 2 are connected to the mover. The sub-cavity 131 cooperates to ensure that the mover 2 is installed and positioned on the mirror image symmetrical center plane 16 of the stator 1 , so that there is a uniform air gap 5 between the mover 2 and the stator pole pieces 102 on both sides. The mover 2 includes a mover frame 21 and a magnetic steel 22. The mover frame 21 is extended to form an output end 23, which extends out of the actuator through the output hole 132 for connection with the driven mechanism. The magnetic steel 22 has two pairs of magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com